Carbide Ball Teeth, also known as carbide ball inserts, tungsten carbide ball teeth, or conical picks, are a specific type of wear part and cutting tool characterized by their hemispherical (ball-shaped) head made of tungsten carbide. They are primarily designed for robust impact, crushing, and grinding applications, rather than precise shearing or slicing.

Their unique design allows them to transmit high point load forces into the material, making them ideal for breaking extremely hard and abrasive substances.

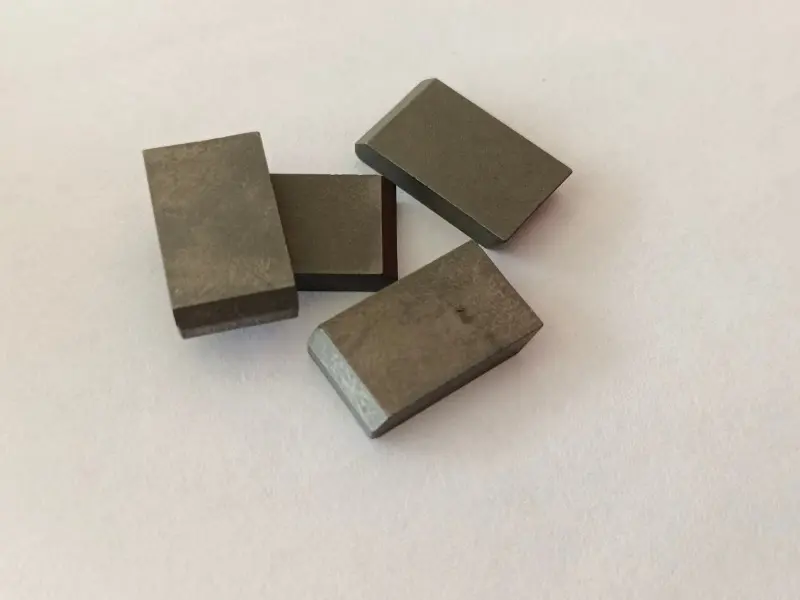

Hemispherical Head: The rounded, ball-like head is the defining feature. This shape allows the tooth to rotate within its holder, promoting even wear around the entire head. This self-sharpening effect significantly extends the tool's service life compared to a fixed-profile tool.

Tungsten Carbide Tip: The head is made from a tough grade of tungsten carbide, providing exceptional impact resistance and abrasive wear resistance.

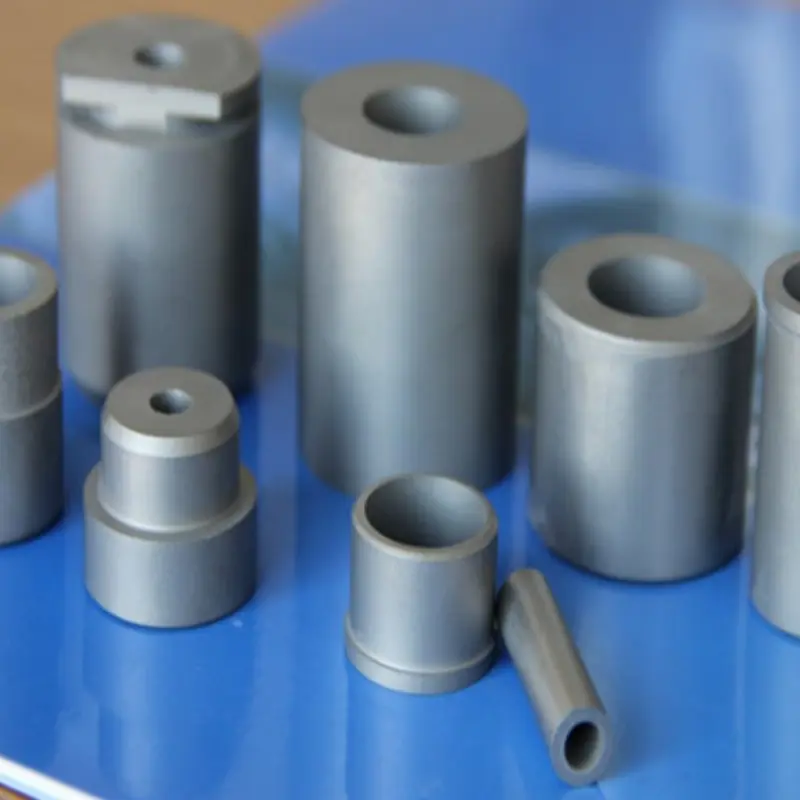

Steel Body/Shank: The carbide head is brazed onto a sturdy steel body, which provides the necessary toughness and ductility to absorb heavy shock loads without breaking. The shank is precision-machined to fit securely into a block or holder.

Retention System: They are held in place by a robust retention system (often a spring clip or a rubber/plastic retainer), which keeps the tooth securely in place while allowing it to rotate during operation.

The operational genius of carbide ball teeth lies in their ability to rotate:

As the machine (e.g., a road planer or miner) applies force, the ball tooth impacts the material.

The asymmetric forces acting on the hemispherical head cause it to rotate slightly in its holder with each impact.

This rotation ensures that wear is distributed evenly across the entire head surface, preventing the formation of flat spots and maintaining a consistently sharp, effective point of contact.

Carbide ball teeth are indispensable in industries involving heavy-duty excavation and surface degradation:

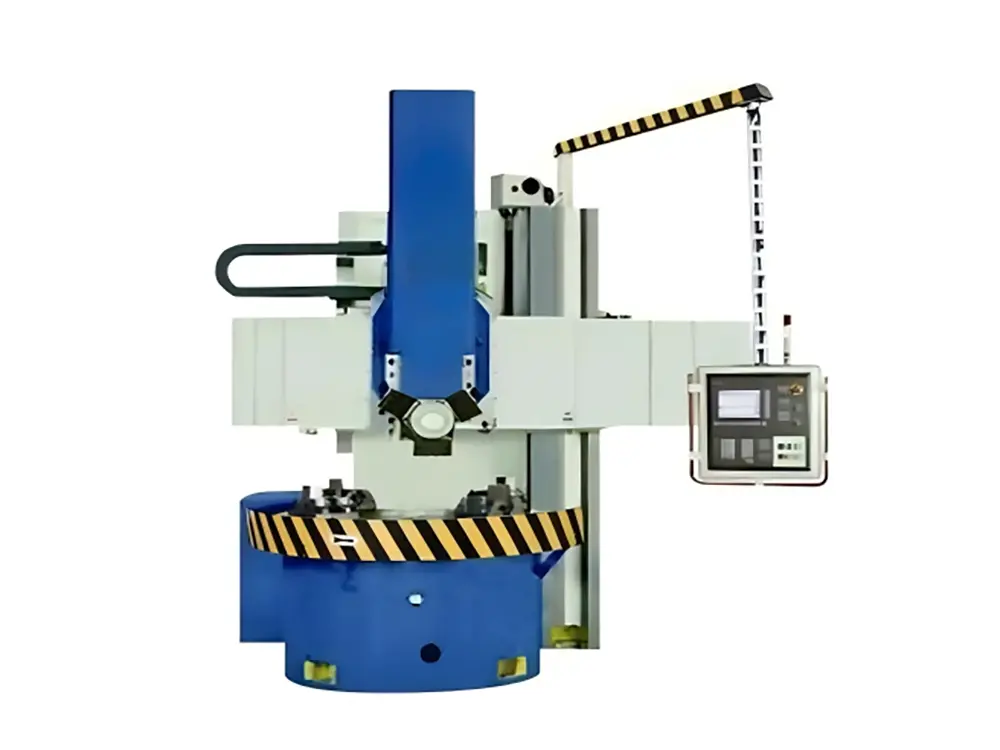

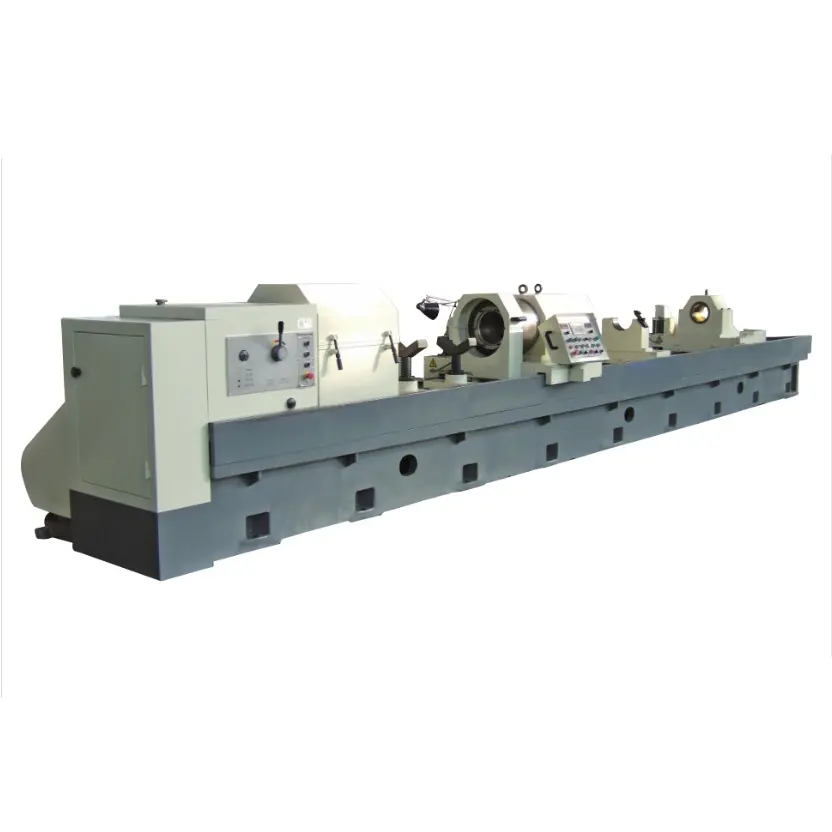

Road Milling & Cold Planing: Mounted on the drums of cold planers (milling machines) to remove asphalt and concrete pavement layers.

Surface Mining & Trenching: Used on continuous surface miners and trenchers to cut through hard rock and strata.

Tunnel Boring & Rock Drilling: Employed on certain types of tunnel boring machines and raise boring heads.

Material Processing: Found in crushers and hammer mills to break down large, hard materials.