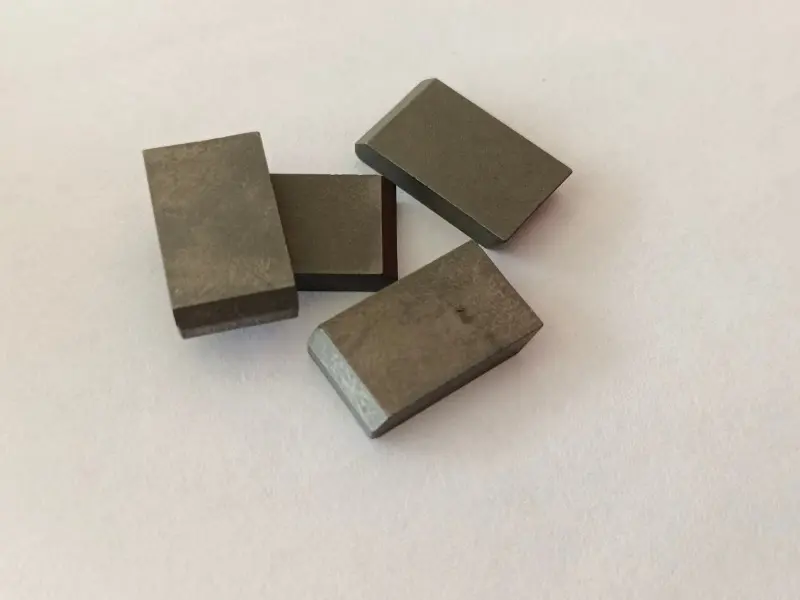

The cemented carbide wear-resistant block for the geology and mining field is a block-shaped cemented carbide component designed for high-wear scenarios in geological and mining operations. It boasts extremely high hardness, wear resistance and impact toughness. It can be directly installed on the wear contact surfaces of mining equipment (such as crusher liners, excavator bucket teeth, scraper conveyor guides, etc.), which can significantly reduce equipment wear, improve operating efficiency, and adapt to harsh working conditions such as rock crushing and ore transportation.

The cemented carbide wear-resistant bushing dedicated to the geology and mining field is made of cemented carbide material with high cobalt content and high hardness. It is used in key parts of geological exploration and mining equipment to provide wear resistance, impact resistance and sealing protection. It can effectively extend the service life of equipment under harsh working conditions (such as high wear, high pressure, and dusty environments), and is suitable for drilling rigs, roadheaders, conveying equipment, etc.

The CD Texture Cutter (Diamond Turning Tool) is a precision cutting tool made of high-quality diamond or cemented carbide substrate with diamond coating. It is mainly used to process uniform and high-gloss CD textures (concentric circular textures) on the surface of metal, composite materials and other workpieces. Widely applied in electronic equipment casings, decorative parts, precision mechanical components and other fields, it features high cutting precision, strong wear resistance and excellent processing surface quality.

The cemented carbide gun drill bit for the geology and mining field is the core component of the gun drill tool. It is made of high-strength and high-wear-resistant cemented carbide material. Suitable for deep hole drilling operations in geological and mining exploration, it can perform efficient drilling in hard geological bodies such as rocks and ores. It features high drilling precision, smooth chip removal and long service life, and is compatible with various geological drilling rigs.

Cemented carbide tapered ball tooth is a key cutting component of geological and mining equipment (such as DTH drills, roller cone drills). It adopts a tapered structure design, and the ball head has excellent impact toughness and wear resistance. It can effectively crush hard rocks and ores, and is suitable for drilling, blasting and other operations. It has the advantages of high crushing efficiency, strong impact resistance and being not easy to damage.

The wear-resistant bushing is a versatile wear-resistant protective component made of high-quality cemented carbide material. It is widely used in machinery manufacturing, automation equipment, hydraulic systems and other fields to reduce friction and wear between moving parts and protect base parts. It has the characteristics of compact structure, easy installation, good wear resistance and long service life, and can be customized in size and material according to different working conditions.

Cemented carbide insert is a common core tool component in metal cutting processing. It is made of different grades of cemented carbide and has the characteristics of high hardness, high wear resistance and high temperature resistance. Suitable for various cutting processes such as turning, milling, drilling and planing, it can process various workpieces such as steel, cast iron, non-ferrous metals and composite materials. Different shapes, sizes and cutting edge forms can be customized according to processing requirements.

Cemented carbide mushroom-shaped ball tooth is named for its mushroom-like shape. It is an efficient crushing tool component made of cemented carbide material. The head is round and thick, with excellent impact resistance and wear resistance. It is mainly used in crushers, impact drills, roadheaders and other equipment. Suitable for crushing hard materials such as rocks, ores and concrete, it has high crushing efficiency and long service life.

Cemented carbide flat-top tooth is a cemented carbide toothed component with a flat top. It has high strength, high wear resistance and good load distribution capacity. It is mainly used in extrusion, crushing, forming and other processes, and is widely applied in mining machinery, construction machinery, powder metallurgy equipment and other fields. It can effectively bear high pressure and impact load, and is suitable for processing materials with high hardness.

Cemented carbide ball tooth is a multi-functional cemented carbide cutting/crushing component with a spherical head. It has excellent impact toughness, wear resistance and cutting performance. Widely used in mining, tunnel excavation, building crushing and other fields, it is installed on drilling rigs, crushers, excavators and other equipment. It can efficiently crush hard materials such as rocks, ores and concrete, and is a key wearing part in the geology, mining and construction industries.

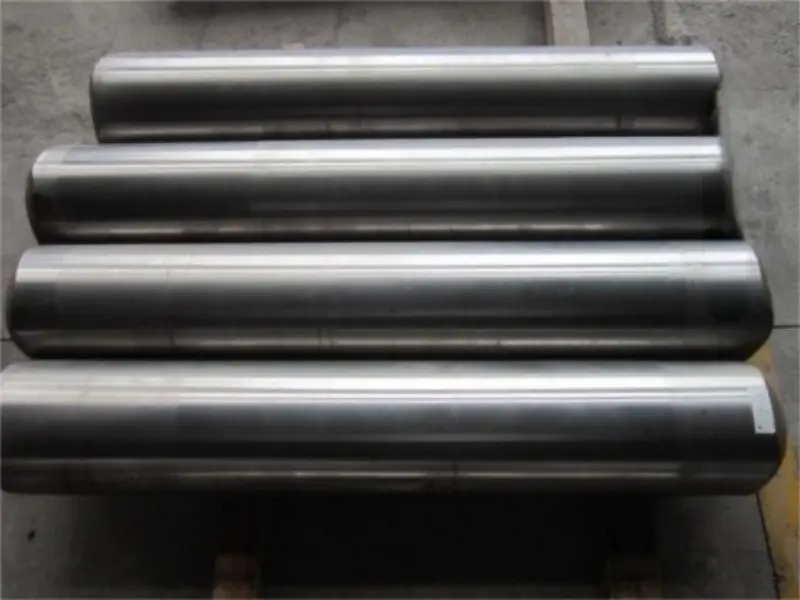

Nickel-based wrought superalloys are a class of high-performance materials designed for exceptional mechanical strength, creep resistance, and structural stability at elevated temperatures, typically above 540°C (1000°F). The term “wrought” signifies that these alloys are shaped into their final form through thermomechanical processes such as forging, rolling, or extrusion, which results in a fine, directional grain structure that provides superior tensile and fatigue properties compared to their cast counterparts. They are the backbone of high-temperature rotating components in aerospace and power generation, where failure is not an option.

Nickel-based corrosion-resistant alloys are a class of advanced metallic materials engineered primarily to withstand extreme corrosive environments. Their foundation is a nickel (Ni) matrix, which is inherently resistant to many corrosives, alloyed with other key elements—primarily chromium (Cr), molybdenum (Mo), and sometimes copper (Cu) and nitrogen (N)—to create a versatile and powerful family of materials for the most aggressive chemical and industrial applications. They are the go-to solution when stainless steels are no longer sufficient.