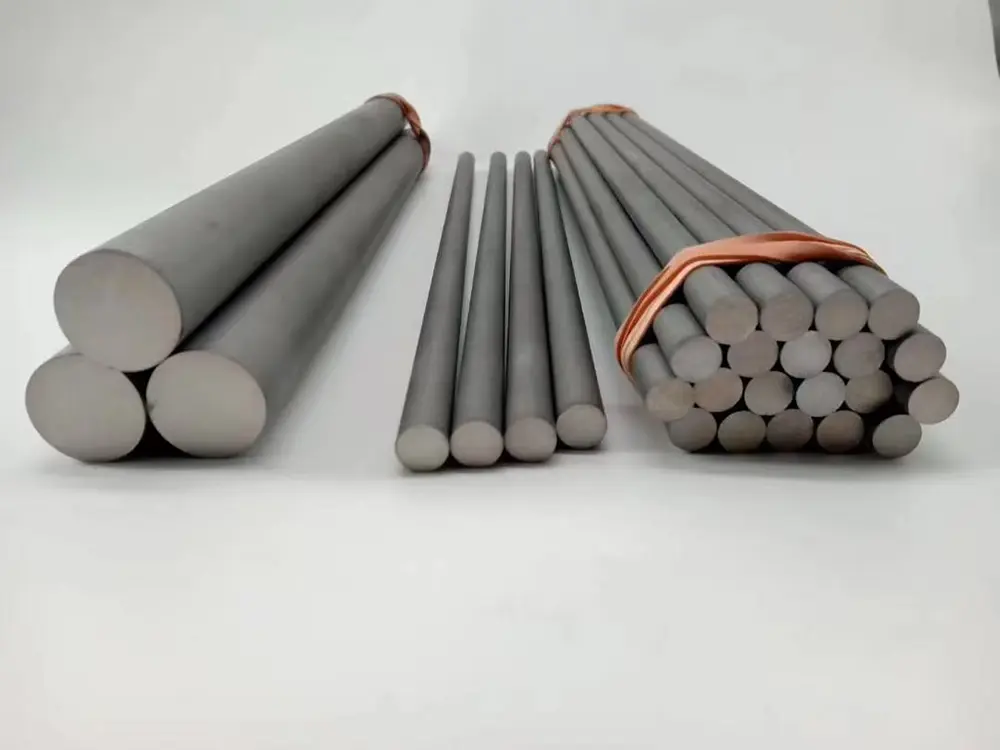

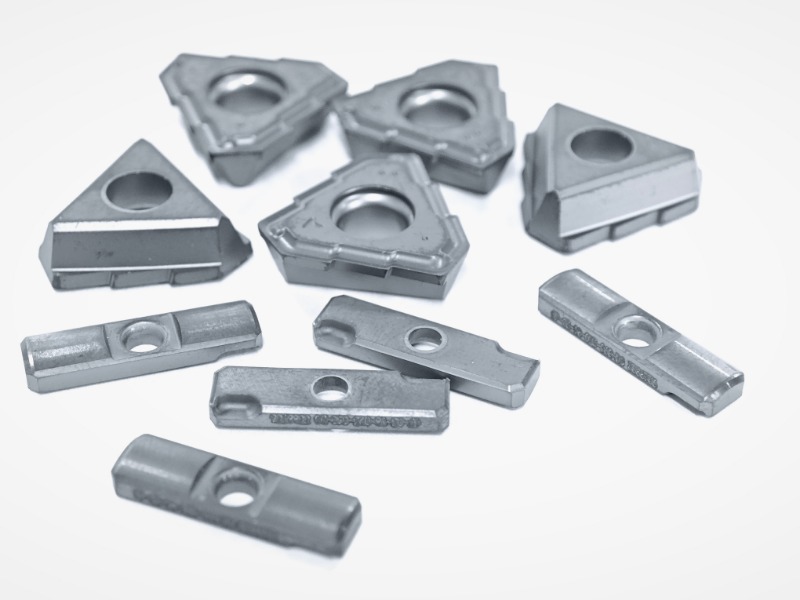

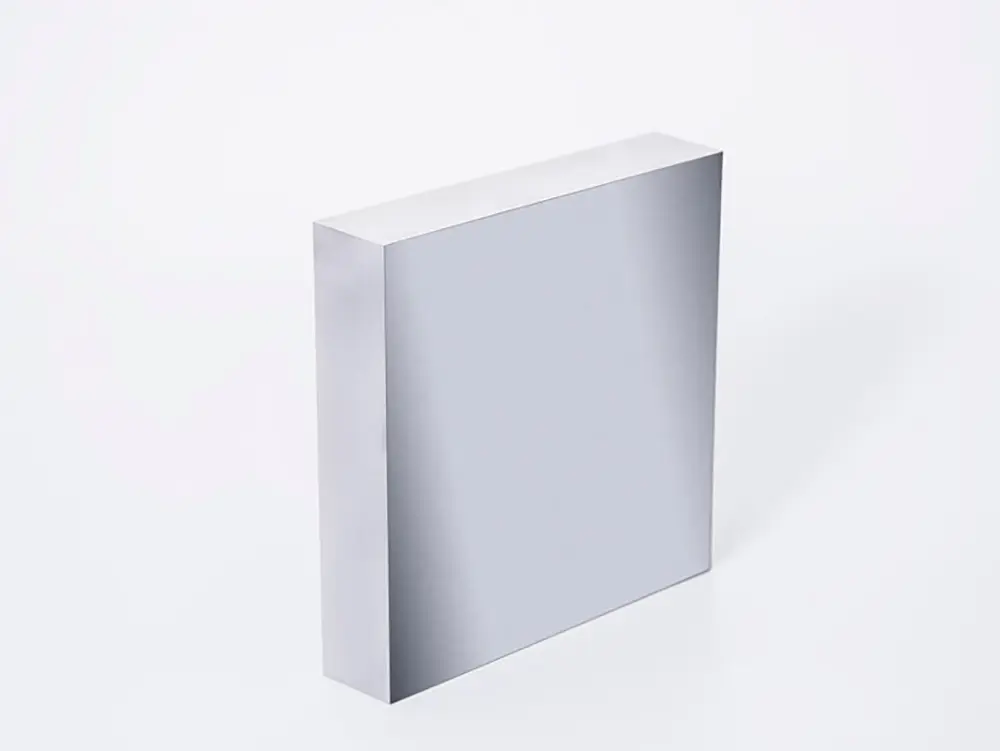

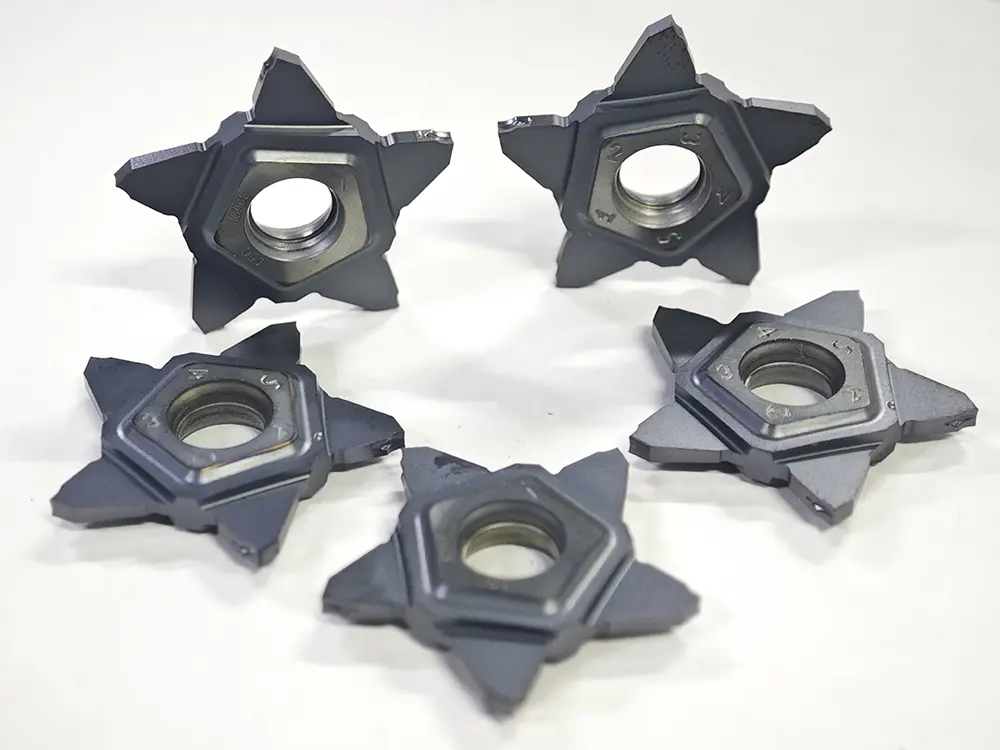

Carbide cutting teeth refer to the tooth-like or tip components made from tungsten carbide, a composite material known for its exceptional hardness, wear resistance, and durability. These teeth are typically brazed or mounted onto various tools and machinery to serve as the primary cutting, drilling, or grinding surface.

The following table summarizes their key characteristics and primary applications:

High Hardness & Wear Resistance: Extremely hard, they effectively resist abrasion during operation, maintaining a sharp cutting edge for a long service life.

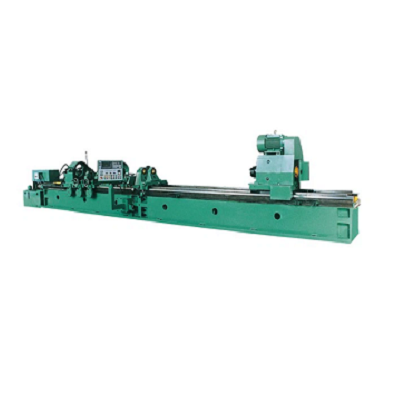

Rock & Construction Drilling: Used as the cutting elements on drill bits for oil and gas drilling, mining, and tunnel boring.

Impact Resistance: Possesses good toughness and can withstand significant impact and vibration without fracturing.

Woodworking & Milling Tools: Serve as the cutting tips on saw blades, router bits, and milling tools for processing wood and composites.

High Strength & Heat Resistance: Retains its hardness and strength even at elevated temperatures generated during high-speed cutting.

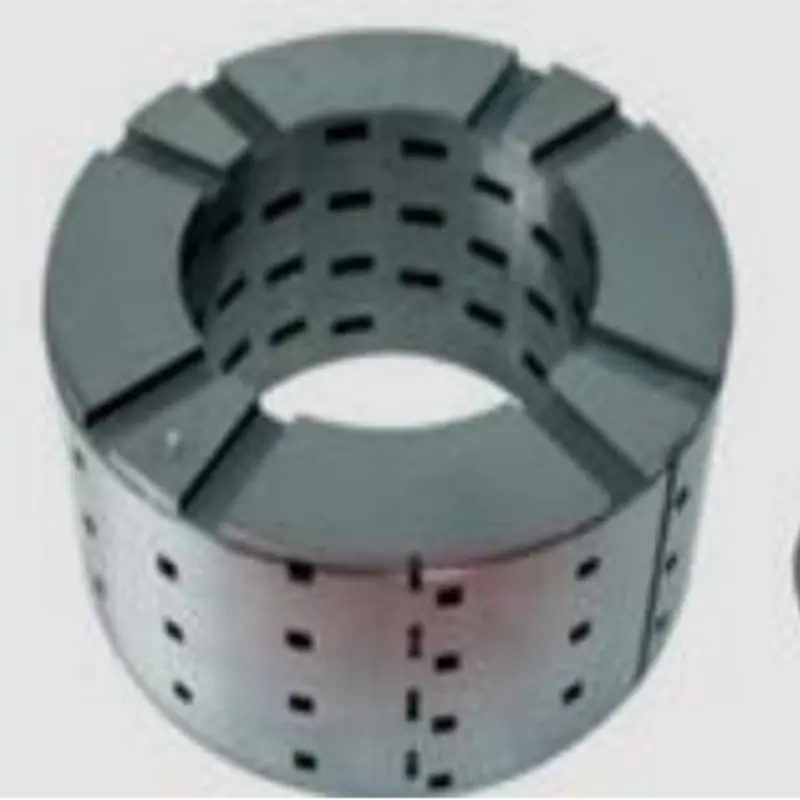

Mining and Road Rehabilitation: Installed on picks and drums of continuous miners, roadheaders, and asphalt planers for cutting and fracturing hard materials.