Carbide drill bits are high-performance cutting tools designed for drilling into hard, abrasive, or challenging materials. They are distinguished by their cutting edges or tips, which are made from tungsten carbide, a composite material known for its superior hardness and wear resistance compared to standard high-speed steel (HSS).

Exceptional Hardness & Wear Resistance: Tungsten carbide is significantly harder than steel. This allows carbide drill bits to maintain a sharp cutting edge for much longer, especially when drilling abrasive materials like masonry, composites, or certain metals.

High Heat Resistance: They can withstand the high temperatures generated by high-speed drilling without losing their hardness (a property known as "red-hardness"). This reduces the risk of the bit overheating and failing.

Brittleness: While extremely hard, carbide is also more brittle than steel. This makes some carbide bits more susceptible to chipping or breaking under lateral stress or impact if not used correctly.

High Rigidity: Carbide has a high modulus of elasticity, meaning it deflects (bends) less than steel during drilling. This is critical for maintaining precision and hole accuracy.

Solid Carbide Drills: The entire drill bit body is made of solid tungsten carbide. These are the most rigid and high-performance type, typically used in CNC machining for metals (e.g., steel, cast iron, heat-resistant alloys) and composites. They are excellent for precision drilling but are also the most brittle and expensive.

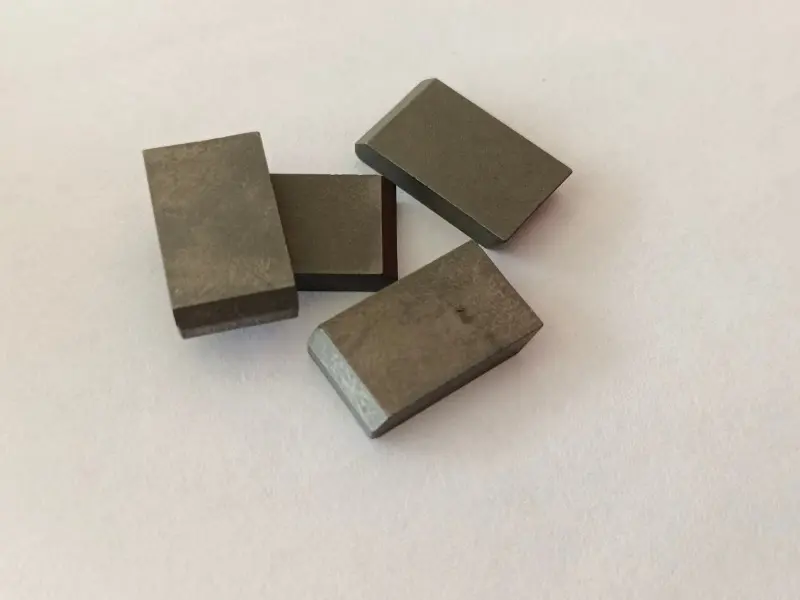

Carbide-Tipped Drills: These bits have a body made of steel (for toughness and shock absorption) with small tips of tungsten carbide brazed onto the cutting edges. This combines the durability of steel with the hard-wearing properties of carbide. They are very common in masonry drills (e.g., for concrete, brick, stone) and woodworking applications.

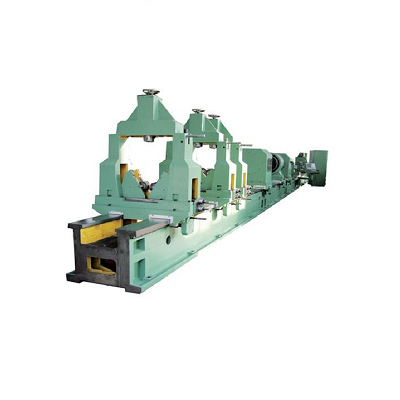

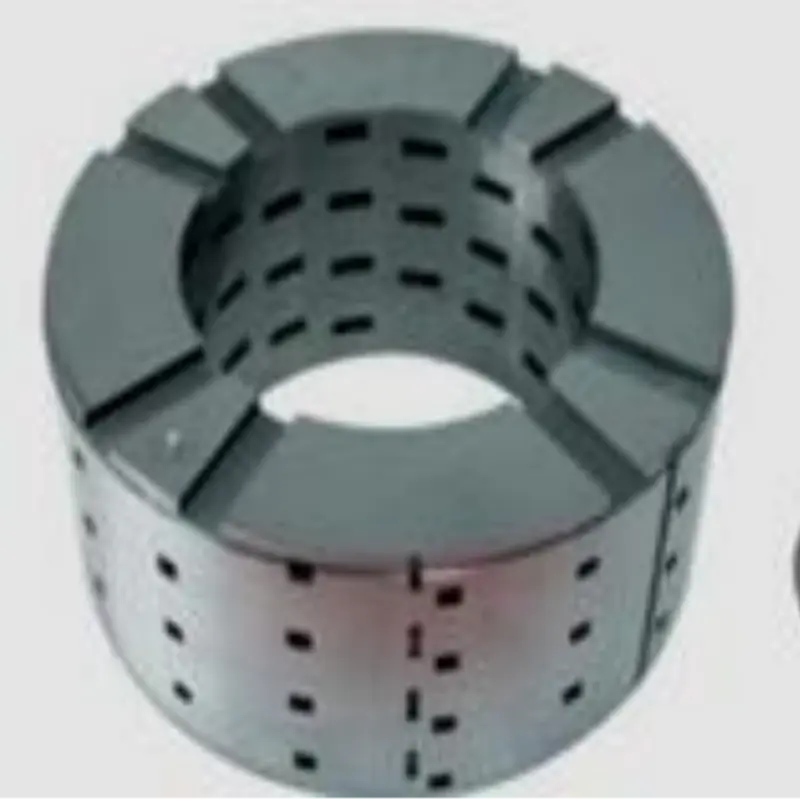

Carbide Insert Drills (Indexable Drills): These are larger-diameter drills used in industrial machining. They feature a steel body with replaceable, indexable carbide inserts. When one cutting edge wears out, the insert can be rotated or replaced to present a fresh edge, making them very cost-effective for high-volume production.

Metalworking: Drilling into hard steels, stainless steel, cast iron, and non-ferrous metals in manufacturing and CNC machining.

Masonry & Construction: Drilling holes in concrete, brick, stone, and tile. (Often recognizable as hammer drill bits with carbide tips).

Woodworking: Used for drilling laminated boards, composite materials, and other abrasive wood products where HSS bits would dull quickly.

Aerospace & Composites: Essential for drilling carbon fiber reinforced polymers (CFRP), fiberglass, and other composite materials without causing delamination.