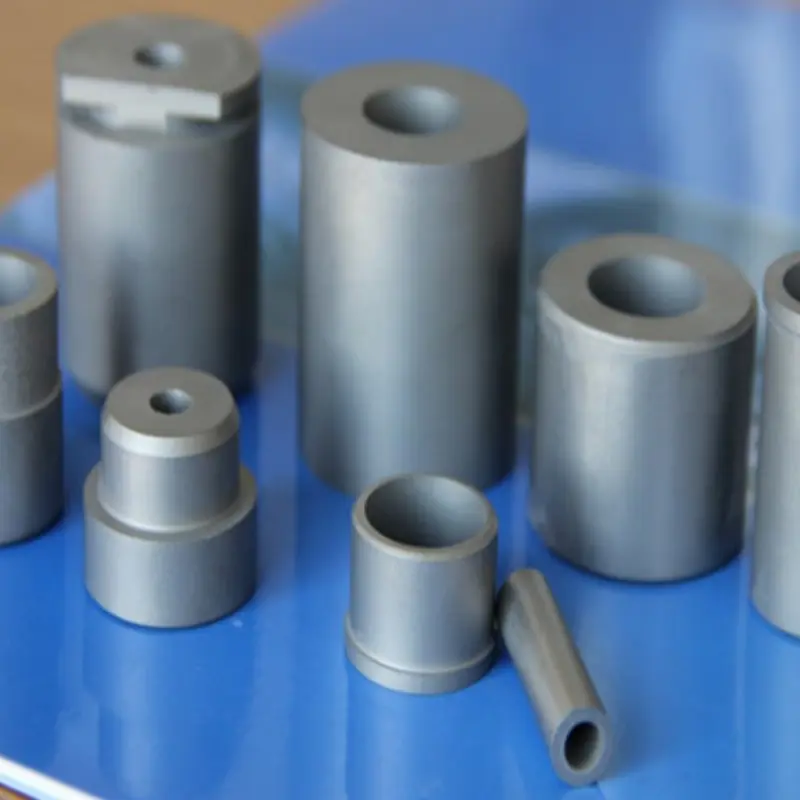

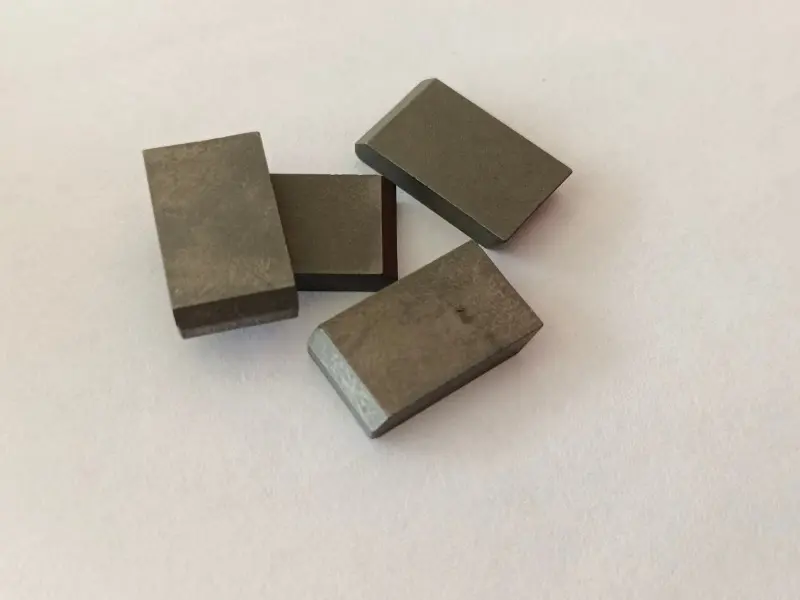

The carbide gun drill feather key is a precision-engineered guide & positioning component for carbide gun drills (deep-hole drilling tools). It ensures stable cutting, accurate hole alignment, and extended tool life during high-precision deep-hole machining. Made of premium tungsten carbide (WC-Co) with advanced coating technology, it delivers exceptional wear resistance and load-bearing capacity in harsh machining environments.

| Item | Details |

| Material | Tungsten Carbide (WC-Co, Grade: K10/K15/K20) + PVD/TiAlN Coating |

| Hardness | 88–92 HRA (or 1500–1800 HV) |

| Size Range | Width: 3–20 mm; Length: 8–50 mm (customizable per DIN 6885 or customer specs) |

| Coating Type | Balzers PVD Coating (reduces friction, enhances wear resistance) |

| Surface Roughness | Ra 0.1–0.8 μm |

| Tensile Strength | ≥1800 MPa |

| Operating Temperature | Up to 600°C (1112°F) |

| Tolerance | ±0.01 mm (high-precision machining) |

| Customization | Available (size, coating, hardness per customer requirements) |

• Exceptional Wear Resistance: Tungsten carbide material + PVD coating ensures 10× longer service life than steel keys, reducing tool replacement frequency.

• High Precision: Tight tolerance (±0.01 mm) guarantees stable guidance for gun drills, maintaining hole straightness (0.3 mm/1000 mm) and coaxiality (0.5 mm/1000 mm).

• Low Friction: PVD coating minimizes friction between the key and drill, preventing overheating and chip adhesion.

• High Load-Bearing Capacity: Withstands high torque and cutting forces in deep-hole drilling (depth-to-diameter ratio up to 250:1).

• Corrosion Resistance: Resists chemical wear from cutting fluids, suitable for wet machining.

This feather key is widely used in deep-hole gun drilling processes across industries:

• Automotive Manufacturing: Drilling engine blocks, crankshafts, cylinder heads, and chassis components.

• Aerospace: Machining aluminum alloy structural parts, turbine blades, and hydraulic system components.

• Mold & Die Industry: Drilling cooling channels and positioning holes in mold steel (e.g., P20, H13).

• Oil & Gas Equipment: Manufacturing drill pipes, pump components, and pressure vessels.

• Hydraulics & Pneumatics: Drilling high-precision holes in hydraulic cylinders and valve bodies.

• General Machinery: Machining precision parts (gears, shafts) requiring deep, accurate holes.

• High-Quality Material: Imported tungsten carbide powder (Germany/Japan) ensures consistent performance.

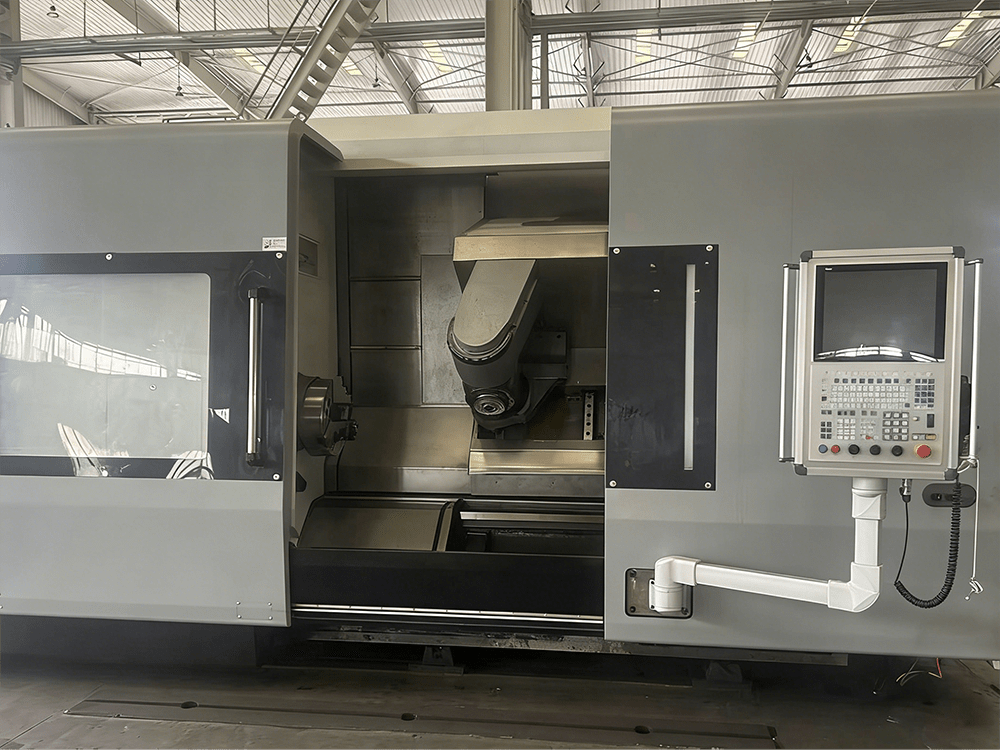

• Advanced Manufacturing: CNC grinding + vacuum coating for strict dimensional control.

• Cost-Effective: Longer service life reduces production downtime and tooling costs.

• Custom Solutions: Tailored sizes/coatings to match specific gun drill models (e.g., Iscar, Guhring, or custom tools).