Carbide Plum Blossom Teeth are a specialized type of tungsten carbide cutting tool characterized by their unique, multi-pointed star shape that resembles a plum blossom. These teeth are designed as highly efficient, multi-faceted cutting elements for extreme abrasive and impact conditions, primarily in the mining and construction industries.

Unique Star-Shaped Head: This is the defining feature. The head has several raised points (typically four or five) arranged around a central axis, creating a profile like a plum blossom or a star. This design creates multiple sharp cutting edges.

Tungsten Carbide Composition: The entire tooth head is made of a tough grade of tungsten carbide, providing exceptional resistance to abrasion and impact from hard rock and concrete.

Multi-Edge Cutting Action: Unlike a simple conical pick, the plum blossom tooth attacks the material with several sharp points and edges simultaneously. This allows for more efficient fracturing and chipping of the material.

Self-Sharpening Effect: As the high points of the star wear down, new, sharper edges are exposed from the lower valleys of the profile. This creates a continuous self-sharpening effect, maintaining cutting efficiency over a longer period.

Steel Body with Retention Groove: The carbide head is brazed onto a high-strength steel shank, which features a groove for a robust spring-retention system, ensuring the tooth stays locked in its holder during operation.

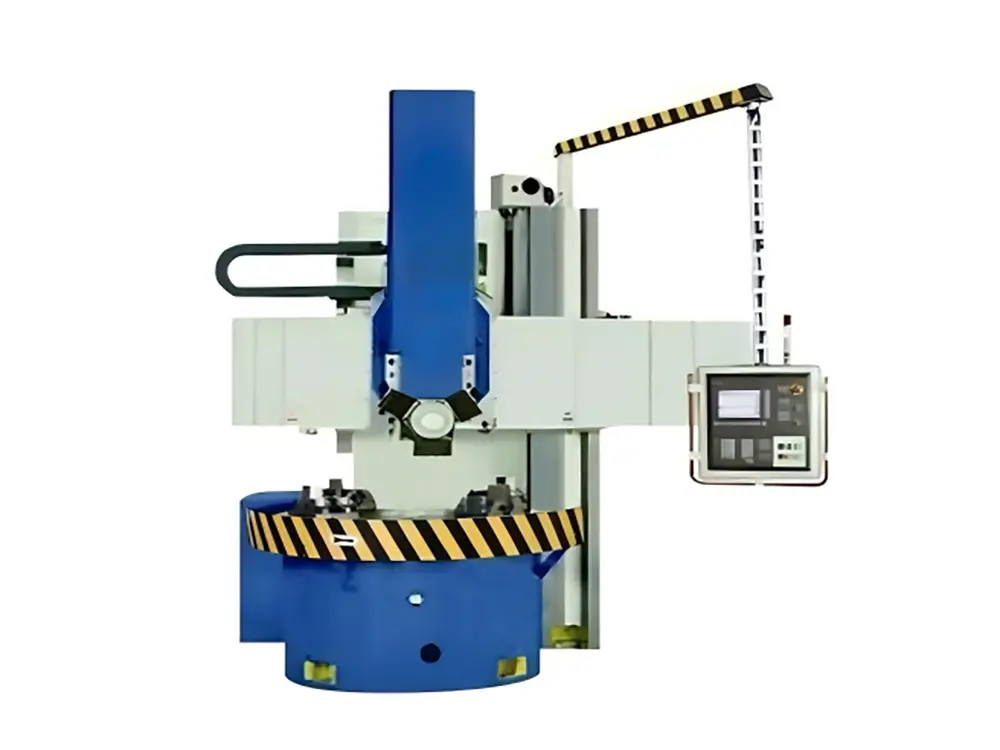

Mounted on the drums of heavy machinery, these teeth rotate and strike the working face.

The multiple sharp points concentrate extreme force on the material, causing it to fracture and spall.

The star shape prevents the tooth from simply grinding the surface and promotes a chiseling and prying action.

The continuous wear across the points ensures that the tooth remains aggressive and effective throughout its life.

These teeth are engineered for the most demanding excavation and milling tasks:

Hard Rock Mining: Used on continuous miners and roadheaders in extremely hard and abrasive rock formations.

Tunnel Boring: Employed on tunnel boring machines (TBMs) where maximum cutting efficiency and tool life are required.

Asphalt and Concrete Milling: Highly effective on cold planers for removing tough, aged pavement and concrete surfaces.

Trenching in Rocky Ground: Used on trencher chains and wheels where both impact and abrasion are significant challenges.

The following table summarizes the key features for a quick overview:

| Feature | Description | Advantage |

| Head Shape | Multi-pointed star shape (Plum Blossom). | Provides multiple sharp cutting edges for efficient material fracture. |

| Material | Solid tungsten carbide head on a steel shank. | Delivers maximum wear resistance and impact strength. |

| Cutting Action | Multi-edge fracturing and chiseling. | More efficient than single-point tools in hard, brittle materials. |

| Core Mechanism | Continuous Self-Sharpening. | As the high points wear, new sharp edges are exposed from the valleys. |

| Key Benefit | Superior Cutting Efficiency & Extended Life in Hard Abrasive Material. | Reduces machine power consumption and downtime for tooth changes. |

| Common Applications | Hard rock mining, tunnel boring, heavy-duty pavement milling. | The premium choice for the most challenging cutting environments. |

In summary, Carbide Plum Blossom Teeth represent an advanced evolution in cutting tool design. Their unique star-shaped, self-sharpening geometry makes them significantly more efficient and durable than conventional picks when operating in the world's hardest and most abrasive materials.