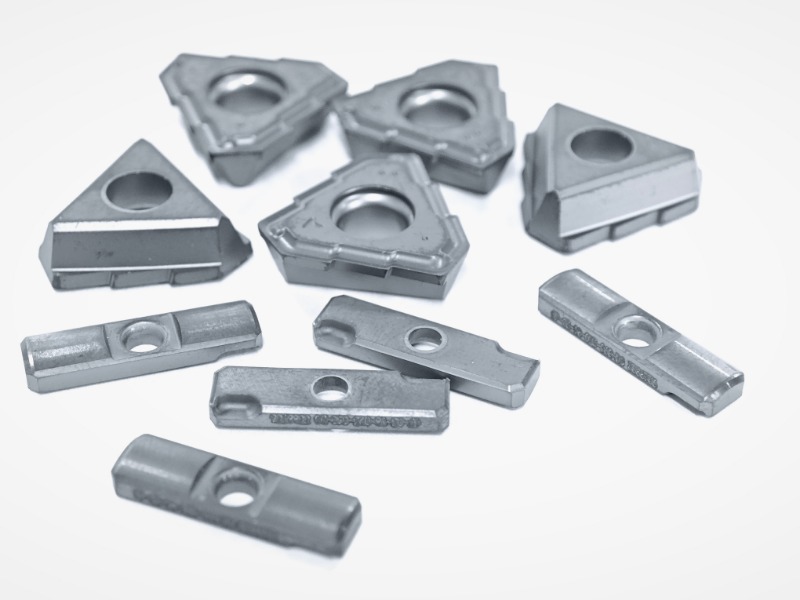

Features:

1.Use high-quality tungsten carbide as raw material.

2.Adopt the world advanced preparation technology.

3.Various types can be produced, with German import automatic extrusion equipment.

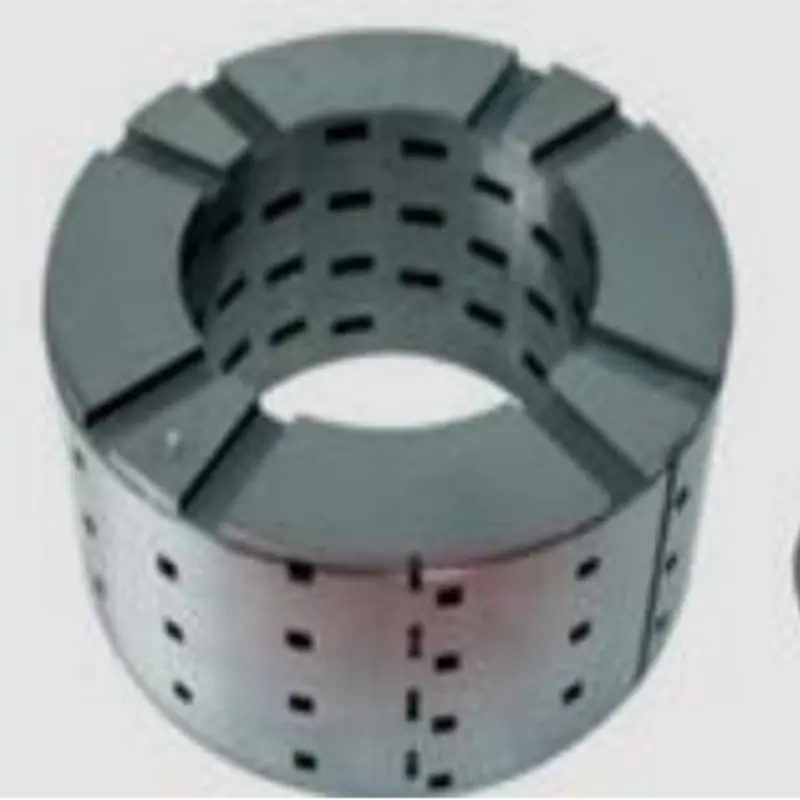

A Grade Carbide is known for its vast selection of premium carbide coolant rods with central, parallel, or helical channels set at a variety of angles. Our innovative, best-in-class coolant channel technology enhances the performance and life of your carbide.

AGrade Carbide rods with a straight hole, as sintered, L=330mm

| Dimension | As sintered stock | ||

| D(Out diameter )mm | D(Hole diameter) mm | Length mm | AS10 |

| 2.2 | 0.8 | 330 | x |

| 3.2 | 0.6 | 330 | x |

| 4.2 | 0.6 | 330 | x |

| 6.2 | 1.0 | 330 | x |

| 6.2 | 1.5 | 330 | x |

| 7.2 | 1.1 | 330 | x |

| 8.2 | 1.2 | 330 | x |

| 8.2 | 1.3 | 330 | x |

| 8.2 | 1.5 | 330 | x |

| 8.2 | 2.0 | 330 | x |

| 10.2 | 1.0 | 330 | x |

| 10.2 | 1.6 | 330 | x |

| 10.2 | 2.0 | 330 | x |

| 12.2 | 1.5 | 330 | x |

| 12.2 | 2.0 | 330 | x |

| 12.2 | 3.0 | 330 | x |

| 14.2 | 2.0 | 330 | x |

| 14.2 | 2.5 | 330 | x |

| 14.2 | 3.0 | 330 | x |

| 16.2 | 2.0 | 330 | x |

| 16.2 | 3.0 | 330 | x |

| 18.2 | 3.0 | 330 | x |

| 20.2 | 2.0 | 330 | x |

| 20.2 | 3.0 | 330 | x |

| 20.2 | 3.5 | 330 | x |

| 22.2 | 3.0 | 330 | x |

| 24.2 | 4.0 | 330 | x |

| 25.2 | 4.0 | 330 | x |

| 26.2 | 4.0 | 330 | x |

| 28.2 | 4.0 | 330 | x |

| 30.2 | 5.0 | 330 | x |

| 32.2 | 5.0 | 330 | x |

X: delivery from stock, acc general conditions

Other: Special executions, grades or dimensions upon request

AGrade Tungsten carbide rods with 2 straight coolant holes, as sintered, L=330mm

| Dimension | Stock | Dimension | Stock | |||||||

| D mm | L mm | T mm | D mm | AS10 | D mm | L mm | T mm | D mm | AS10 | |

| 4.2 | 330 | 1.8 | 0.8 | X | 16.2 | 330 | 8.0 | 2.0 | X | |

| 5.2 | 330 | 1.9 | 0.8 | X | 17.2 | 330 | 6.0 | 2.0 | X | |

| 6.2 | 330 | 1.5 | 0.9 | X | 17.2 | 330 | 7.9 | 2.0 | X | |

| 6.2 | 330 | 3.0 | 1.2 | X | 18.2 | 330 | 6.0 | 2.0 | X | |

| 7.2 | 330 | 1.4 | 0.8 | X | 18.2 | 330 | 8.9 | 2.0 | X | |

| 7.2 | 330 | 3.4 | 1.0 | X | 19.2 | 330 | 6.0 | 2.0 | X | |

| 8.2 | 330 | 2.6 | 0.9 | X | 19.2 | 330 | 8.8 | 2.0 | X | |

| 8.2 | 330 | 2.8 | 1.0 | X | 20.2 | 330 | 6.0 | 2.0 | X | |

| 8.2 | 330 | 3.3 | 0.9 | X | 20.2 | 330 | 9.8 | 2.5 | X | |

| 9.2 | 330 | 2.5 | 1.0 | X | 21.2 | 330 | 6.0 | 2.0 | X | |

| 10.2 | 330 | 3.5 | 1.5 | X | 21.2 | 330 | 9.8 | 2.5 | X | |

| 10.2 | 330 | 4.9 | 1.4 | X | 22.2 | 330 | 6.0 | 2.0 | X | |

| 10.2 | 330 | 5.0 | 1.2 | X | 22.2 | 330 | 10.8 | 2.5 | X | |

| 11.2 | 330 | 3.4 | 1.2 | X | 23.2 | 330 | 7.3 | 2.0 | X | |

| 11.2 | 330 | 4.9 | 1.4 | X | 23.2 | 330 | 10.8 | 2.5 | X | |

| 12.2 | 330 | 3.5 | 0.9 | X | 24.2 | 330 | 7.3 | 2.0 | X | |

| 12.2 | 330 | 6.2 | 1.5 | X | 24.2 | 330 | 11.8 | 3.0 | X | |

| 13.2 | 330 | 3.4 | 1.2 | X | 25.2 | 330 | 7.3 | 2.0 | X | |

| 13.2 | 330 | 5.9 | 1.8 | X | 25.2 | 330 | 11.8 | 3.0 | X | |

| 14.2 | 330 | 3.5 | 1.5 | X | 26.2 | 330 | 12.8 | 3.0 | X | |

| 15.2 | 330 | 4.9 | 1.5 | X | 28.2 | 330 | 13.8 | 3.0 | X | |

| 15.2 | 330 | 6.9 | 2.0 | X | 30.2 | 330 | 13.8 | 3.0 | X | |

| 16.2 | 330 | 5.0 | 1.5 | X | 32.2 | 330 | 13.8 | 3.0 | X | |

| 16.2 | 330 | 6.2 | 2.0 | X | 34.2 | 330 | 13.8 | 3.0 | X | |

X: delivery from stock, acc general conditions

Other: Special executions, grades or dimensions upon request