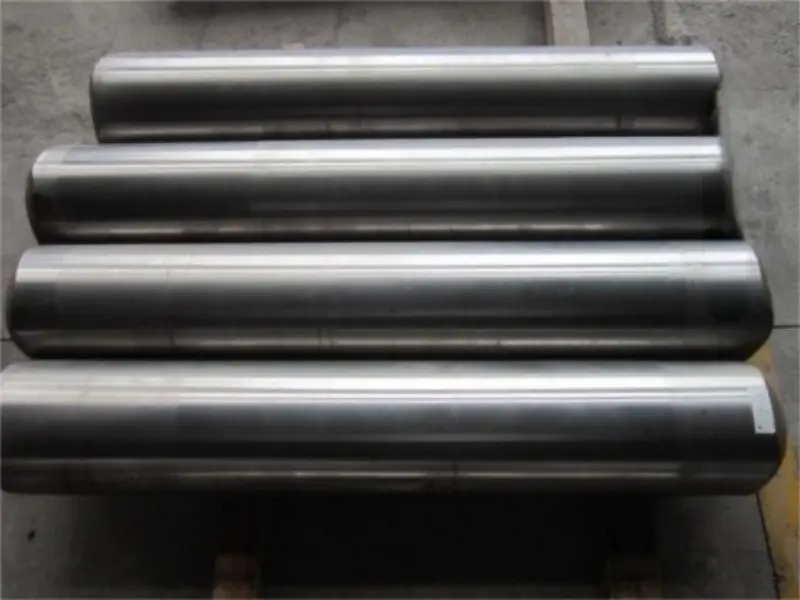

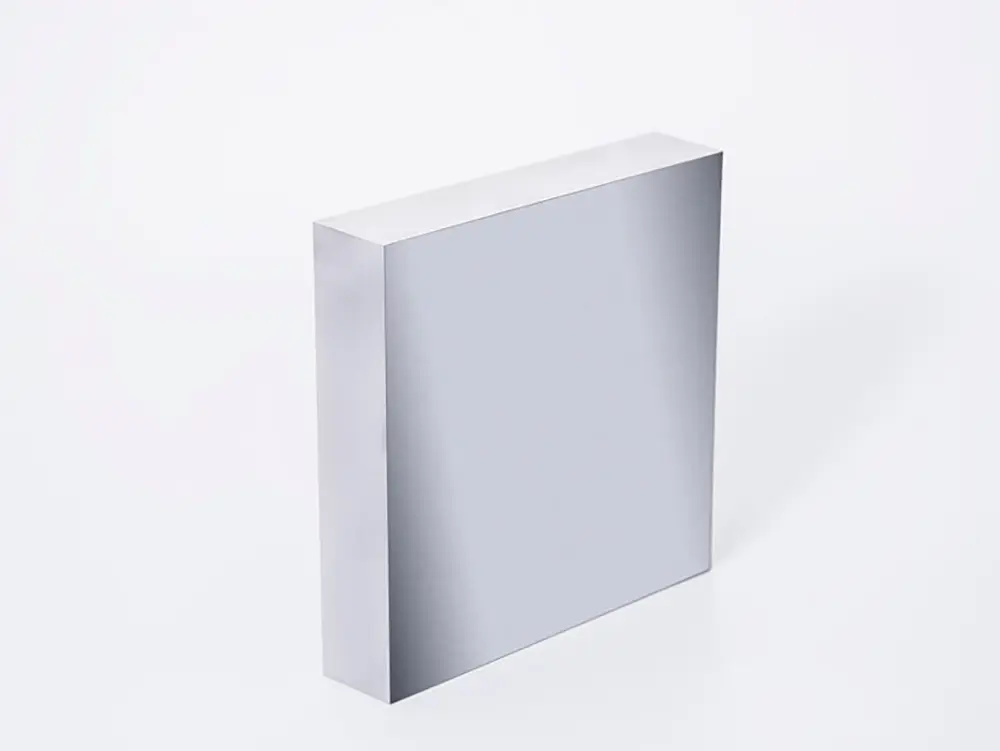

Carbide strips, also known as tungsten carbide strips or cemented carbide flat bars, are rectangular or flat-bar-shaped pieces made from tungsten carbide. They are engineered to provide superior wear resistance as protective liners or cutting edges on machinery and equipment subjected to severe abrasion.

Exceptional Abrasion Resistance: The primary property, offering excellent protection against wear from sand, gravel, ore, coal, and other abrasive materials.

High Strength and Rigidity: Possesses high compressive strength and maintains its shape under heavy load, resisting deformation.

Good Impact Toughness: With proper grade selection, it can withstand moderate levels of impact alongside extreme abrasion.

Customizable Geometry: Available in various standard and custom thicknesses, widths, and lengths to suit different application needs.

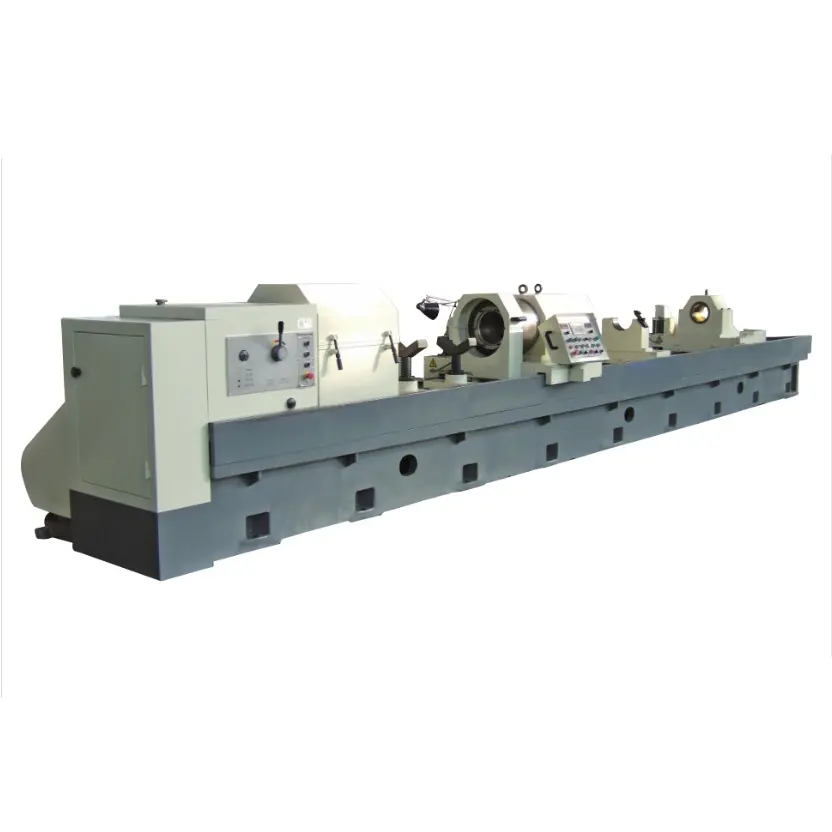

Carbide strips are manufactured through a powder metallurgy process:

Powder Preparation: Tungsten carbide powder is mixed with a cobalt (or nickel) binder.

Pressing: The powder mixture is pressed in a mold to form a "green" strip of the desired dimensions.

Sintering: The pressed strip is heated in a vacuum furnace at high temperatures. This sinters the powder particles, creating a dense, solid, and incredibly hard material.

Carbide strips are widely used across industries as a cost-effective solution to extend equipment life by protecting vulnerable surfaces.

Wear Protection Liners: Bonded or bolted onto surfaces in equipment like:

Chutes, Hoppers, and Silos: To resist abrasion from falling bulk materials.

Fan Blades and Housing: In industrial fans handling dusty or particulate-laden air.

Pump Casings and Impellers: For handling abrasive slurries.

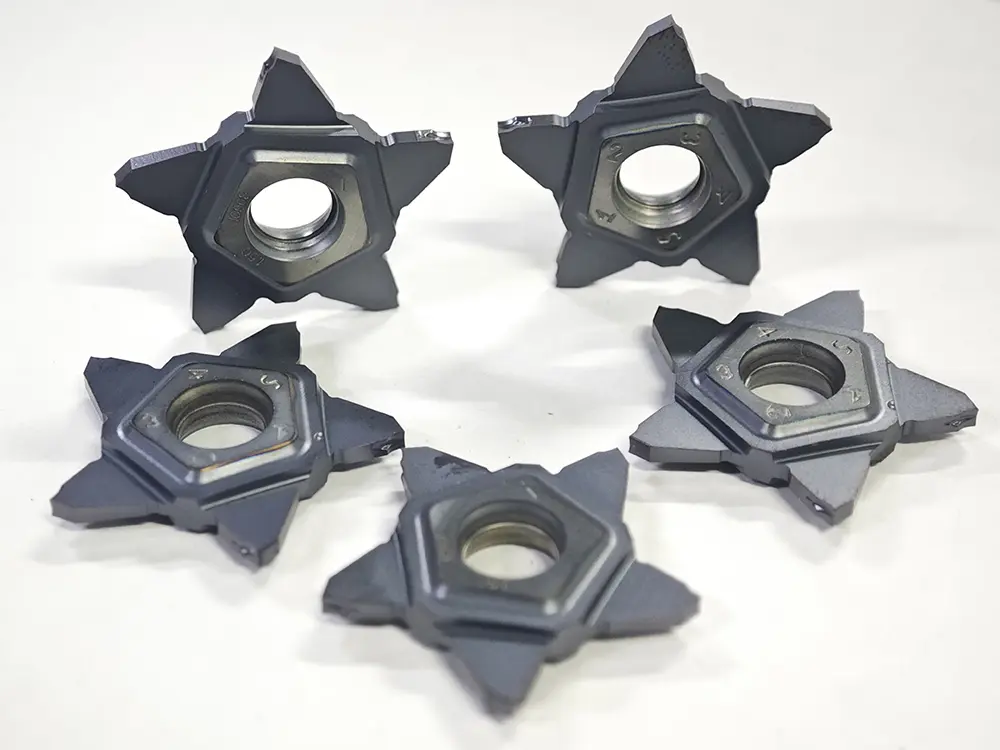

Cutting and Shearing Edges: Used as the sharp, durable edge on:

Circular Saw Blades for cutting wood, plastics, and non-ferrous metals.

Shear Blades for metal processing.

Paper and Plastic Cutting Knives.

Guide Rails and Wear Parts: Used in automation, conveyors, and machinery where components are subject to constant sliding friction.

The following table summarizes the key features for a quick overview:

| Feature | Description | Advantage |

| Form | Rectangular or flat-bar shaped tungsten carbide. | Ideal for protecting flat or curved surfaces and creating long, straight cutting edges. |

| Material | Tungsten carbide with a cobalt/nickel binder. | Provides a perfect balance of wear resistance and mechanical strength. |

| Manufacturing | Powder pressing and sintering. | Ensures a consistent, high-quality, and pore-free structure. |

| Core Function | Abrasion-resistant protection & precision cutting. | Significantly extends the service life of critical equipment components. |

| Key Benefit | Reduced Downtime and Maintenance Costs. | Protects less durable base materials, leading to higher operational efficiency. |

| Common Applications | Wear liners, saw blade tips, shear blades, guide rails. | A versatile and essential component for combating wear in industrial settings. |

In summary, Carbide Strips are a fundamental and highly effective engineering solution for combating wear. Their simple strip form makes them incredibly versatile for application as protective armor or sharp, long-lasting edges, providing a reliable and economical way to enhance the durability of machinery operating in abrasive environments.