The term “Carbide Water Tap” does not typically refer to a standard household faucet. Instead, it describes a specialized tungsten carbide valve component or a wear-resistant tap used to control the flow of water, slurry, or other abrasive fluids in industrial settings. The “carbide” designation indicates that the critical wear-prone parts of this valve are made from or protected by tungsten carbide to ensure extreme durability.

Extreme Abrasion Resistance: Tungsten carbide components within the tap resist wear from sand, silt, fine particles, and other suspended solids in the water, which would quickly degrade a standard steel valve.

Corrosion Resistance: Offers good resistance to corrosion, especially when using specific grades with nickel binders, prolonging life in various water qualities.

Long Service Life: The primary advantage is a dramatically extended operational lifespan in harsh conditions, reducing maintenance frequency and downtime.

High Pressure Rating: The strength of carbide allows these taps (or their critical internals) to function reliably in high-pressure systems.

An entire "water tap" is rarely made of solid carbide due to cost and brittleness. Instead, it is used in two main ways:

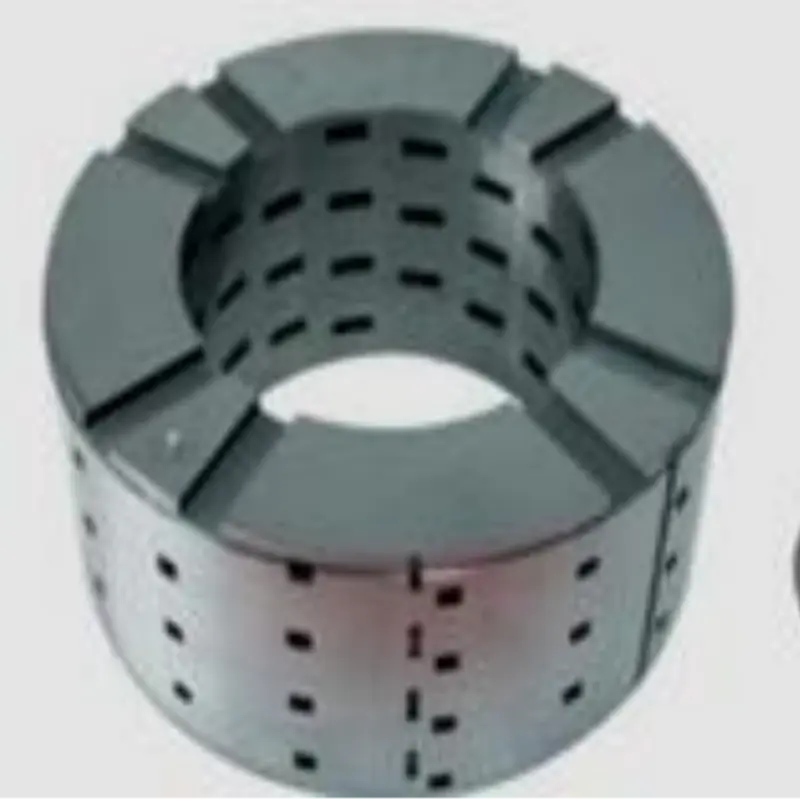

Carbide Trim Valves: The valve body is made of standard materials like stainless steel or carbon steel, but the internal components ("trim") that contact the flow are made of tungsten carbide. This includes:

Seat: The stationary sealing surface.

Plug/Stem Tip: The moving part that closes against the seat.

Cage: (If present) the component that guides the plug and controls flow.

Solid Carbide Needle Valves: For very precise control of small, high-pressure abrasive flows (e.g., in water jet cutting systems), the entire needle tip may be made of solid carbide.

These components are critical in industries where controlling abrasive fluid flow is essential:

Mining & Mineral Processing: For tailings lines, slurry transport, and dewatering systems.

Water Jet Cutting: As the on/off and control valves for the high-pressure abrasive water stream.

Dredging: Used in valves controlling the flow of water-sediment mixtures.

Power Plant (Ash Handling): For managing abrasive fly ash and bottom ash slurries.

Industrial Water & Wastewater: In systems handling water with high solid content.

The following table summarizes the key features for a quick overview:

| Feature | Description | Advantage |

| Core Concept | A valve with tungsten carbide wear parts for abrasive service. | Solves the problem of rapid valve failure in abrasive fluid applications. |

| Material | Tungsten carbide used for critical internals (trim) or small precise parts. | Provides unmatched wear resistance, extending valve life by orders of magnitude. |

| Key Benefit | Drastically Reduced Maintenance & Downtime. | Lowers the total cost of ownership despite a higher initial investment. |

| Common Wear Mechanism | Abrasive Slurry Erosion. | Specifically engineered to combat this type of damage. |

| Typical Configuration | Carbide trim (seat, plug) inside a robust metal valve body. | A cost-effective design that combines wear resistance with structural strength. |

| Primary Industries | Mining, Dredging, Water Jet Cutting, Ash Handling. | Essential for reliable operation in the most challenging fluid control environments. |

In summary, a Carbide Water Tap is not a common plumbing item but a high-performance industrial valve engineered for reliability where standard valves would fail rapidly. Its use of tungsten carbide for key components makes it the definitive solution for controlling abrasive water and slurry flows, ensuring system integrity and operational continuity.