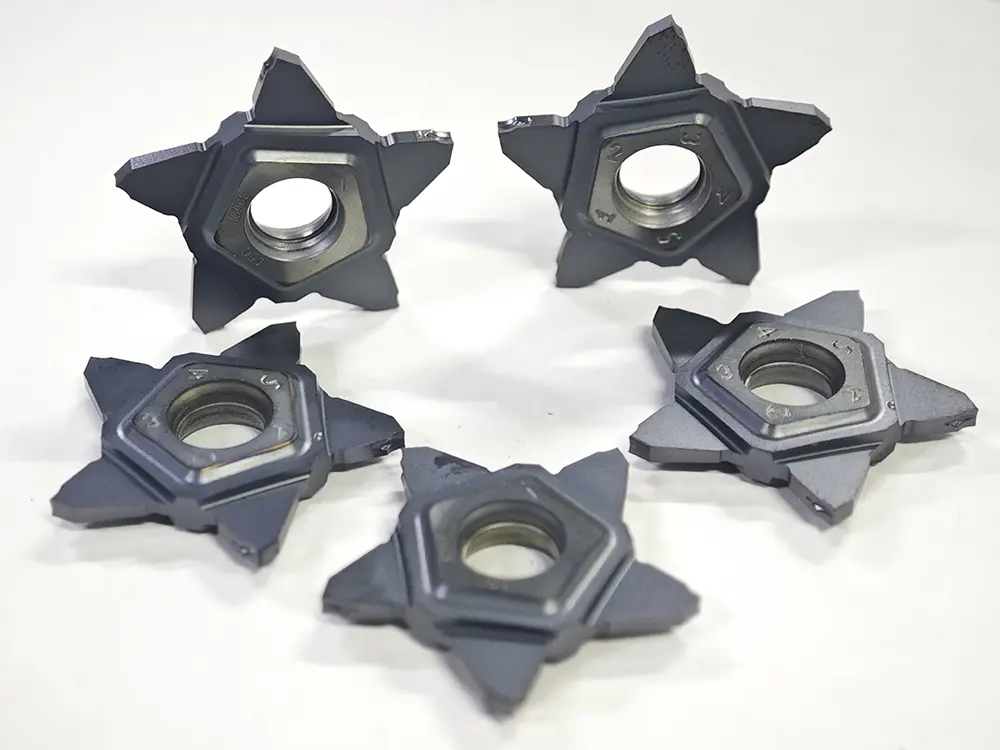

Cemented carbide insert is a common core tool component in metal cutting processing. It is made of different grades of cemented carbide and has the characteristics of high hardness, high wear resistance and high temperature resistance. Suitable for various cutting processes such as turning, milling, drilling and planing, it can process various workpieces such as steel, cast iron, non-ferrous metals and composite materials. Different shapes, sizes and cutting edge forms can be customized according to processing requirements.

| Parameter Item | Description |

| Alloy Grades | AU8, AU12, AS10, AS15, AF6 |

| Cobalt Content (%w/w) | 6.0-15.0 |

| Density (g/cm³) | 13.9-14.8 |

| Hardness (HRA) | 90.3-93.2 |

| Transverse Rupture Strength (N/mm²) | ≥3600 |

| Shape Type | Diamond, Square, Triangle, Round, etc. |

| Size (mm) | 3×3×2 - 30×30×6 (Customizable) |

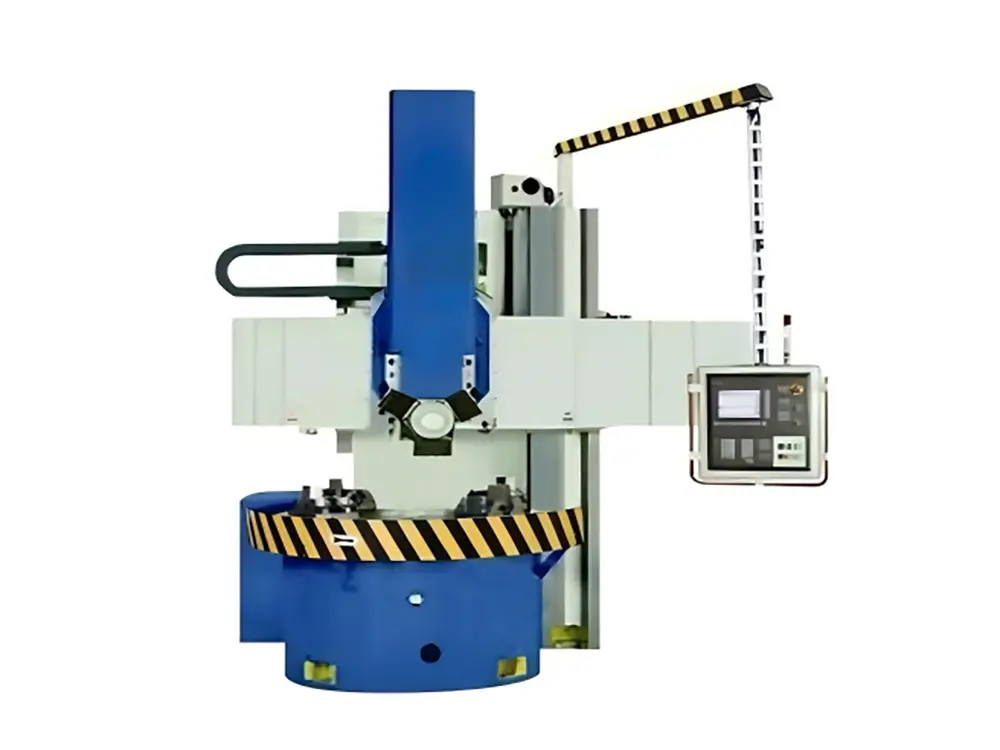

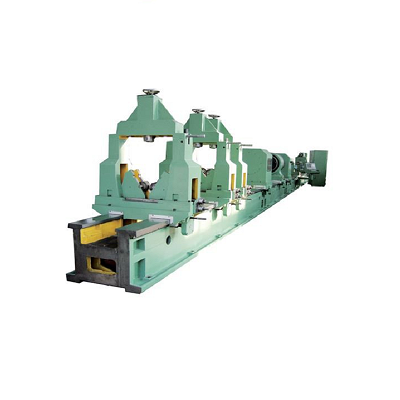

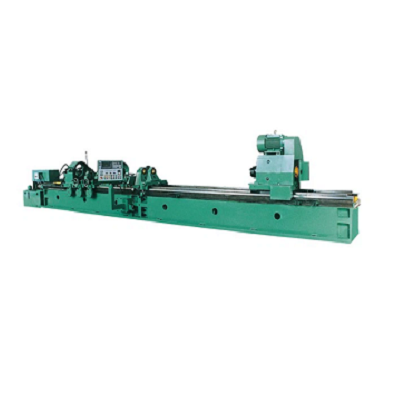

| Applicable Processing Technology | Turning, Milling, Drilling, Boring |