Product parameter project unit parameter process scope Maximum rotary diameter on bed mm Φ1000 Maximum workpiece rotation diameter on the saddle mm Φ800 Maximum turning length (outer circle) mm 2000 Maximum turning diameter of work type of axle mm...

| project | unit | parameter | ||

| process

scope |

Maximum rotary diameter on bed | mm | Φ1000 | |

| Maximum workpiece rotation diameter on the saddle | mm | Φ800 | ||

| Maximum turning length (outer circle) | mm | 2000 | ||

| Maximum turning

diameter of work |

type of axle | mm | Φ700 | |

| Pan categories | mm | Φ800 | ||

| Maximum workpiece

weight |

Plate and sleeve type | kg | 1200 (including fixtures) | |

| type of axle | kg | 2500 (including fixtures) | ||

| principal axis | Bore diameter of spindle | mm | Φ180 | |

| Taper of inner bore of spindle | 1:20 | |||

| Head form of main shaft | A-15 | |||

| Shaft limit speed range/grade | r/min | 5~1200/ second gear, no step in the gear | ||

| Main motor power (S1/S3) | kW | 37/45 | ||

| Constant power speed | r/min | 66 | ||

| Constant power torque | Nm | 4215 | ||

| Manual four-claw single-action hollow chuck diameter | mm | Φ800 (hole φ300) | ||

| Clamping range of the chuck | mm | Straight claws: Φ90-Φ300

Anti-claw: Φ350-Φ650 |

||

| Cardinal limit speed | r/min | 800 | ||

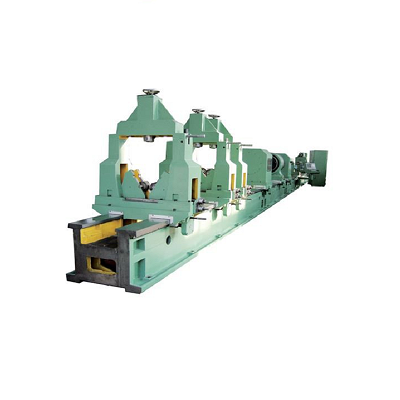

This CNC lathe, designed for semi-finishing and precision turning of shafts and disc-shaped components, features continuous X/Z coordinate control with an FANUC 0i TF5 PLUS numerical control system. It excels in linear interpolation, helical and circular arc turning (including cylindrical, rotary, spherical, and conical surfaces), as well as standard and metric threaded machining. The machine is particularly suited for processing complex-shaped, high-precision components such as discs, sleeves, and shafts.

The machine tool features an integrated 60-degree inclined bed with resin sand molding casting technology, delivering robust structural integrity and wear resistance. The bed's optimized stress distribution enhances chip evacuation efficiency. Its longitudinal and transverse guides employ high-precision heavy-duty rails with a minimum quenching depth of 3mm and a quenched hardness of HRC52 or higher, significantly improving rigidity and vibration resistance. The main spindle is powered by Beijing Chaoshun Z18 series servo motors, driven by an external two-speed gearbox that ensures smooth transmission and precise C-axis positioning/feeding accuracy, enabling both low-speed high-torque cutting and high-speed machining capabilities. Equipped with a 12-station horizontal hydraulic servo tool turret and specialized attachments, the machine demonstrates exceptional process adaptability. This configuration allows single setup for simultaneous turning, drilling, and other operations, effectively reducing auxiliary time during machining.

The design of machine tools embodies contemporary aesthetics, practicality, and user-friendliness. The electrical components are stable and reliable, with the CNC system featuring AC digital drive technology. The X and Z axes employ semi-closed-loop control for high precision and stability, demonstrating strong anti-interference capabilities. The CNC system incorporates advanced features including pitch error compensation, constant-speed cutting, fixed cycles, direct drawing dimension programming, and DNC communication. The machine demonstrates rapid response speed and excellent dynamic rigidity, ensuring superior quality throughout its operation.

Can turn parts of disks with diameter Φ800mm, shafts with diameter Φ700mm and length within 2000mm;

Can process the disk (or shaft) parts with complex geometric shapes and high precision requirements;

Capable of machining internal and external cylindrical surfaces, conical surfaces, circular arc surfaces and other curved surfaces and metric threaded surfaces;

It has the processing of end face, slot, chamfer, drilling, expanding, turning, boring and cutting of parts;

The overall 60° inclined bed body is made of resin sand molding and box tube structure design, which has high rigidity and good absorption and vibration resistance;

The moving guide pair is fully hardened track structure, high frequency quenching and precision grinding, hardness ≥HRC52, improve the rigidity of the machine tool and cutting vibration resistance.

The main transmissionadopts Beijing hyper synchronous Z18 series spindle servo motor, and the external two-speed gearbox can realize 5~1200r.p.m stepless speed change;

The spindle adopts the combination of high precision double row roller bearing and double row angular contact ball bearing, which has high rigidity and high precision;

X/Z axis semi-closed control to achieve stable positioning accuracy.

The configuration of large aperture spindle and large aperture manual four-claw single-action chuck can achieve good clamping stability. It is suitable for processing the inner hole and thread of oil pipes.

The programmable mobile hydraulic tail seat is configured. The tail seat is a full hydraulic structure, and the positioning and locking mode is adopted first (patented structure). The programmable mobile control is suitable for processing cylinder barrel and long shaft workpieces.

Three manual closed roller center frame is equipped, clamping range φ100-φ400mm, maximum roller line speed 300m/min, center frame body is manual locking structure, moving mode is saddle hanging pull (manual).

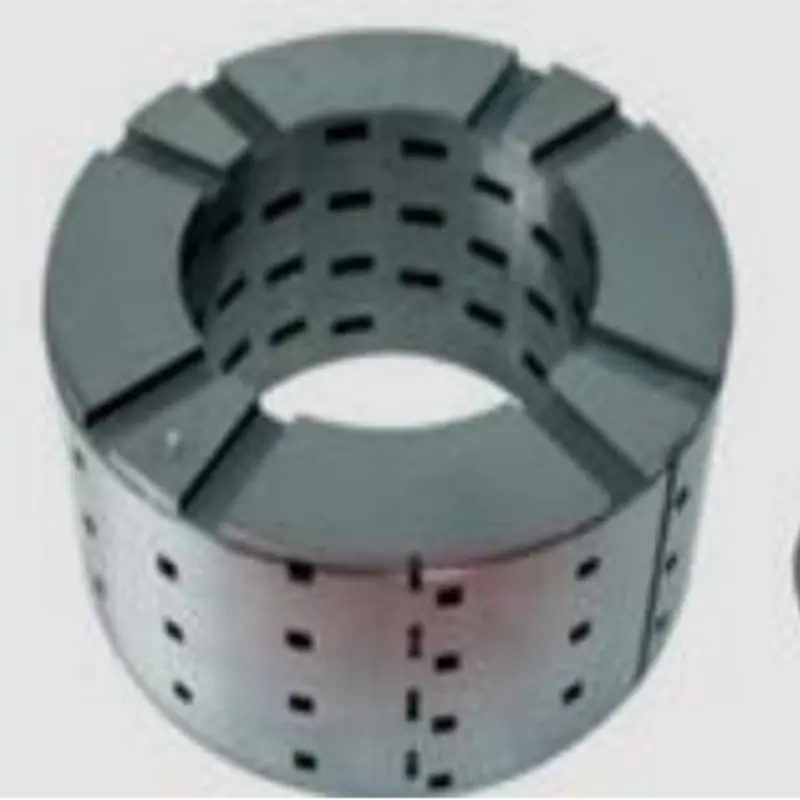

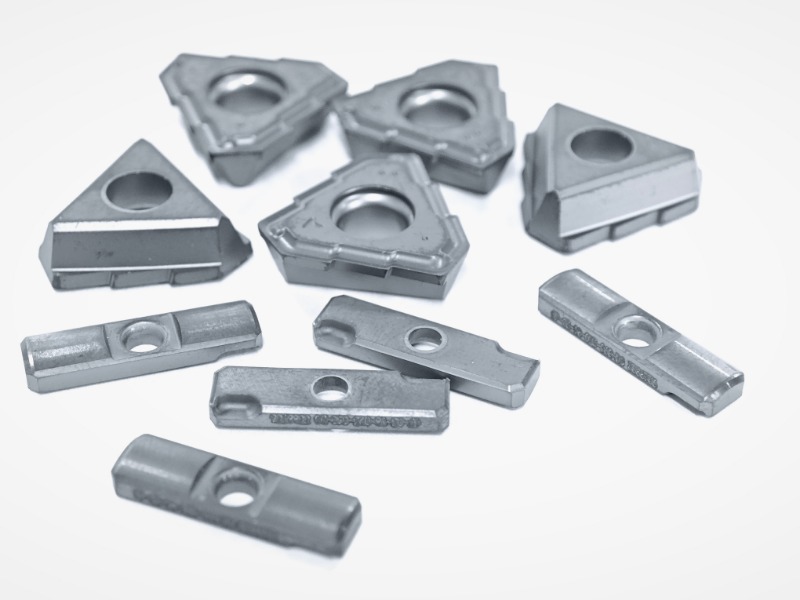

The horizontal 12-station hydraulic servo turret tool holder and groove tool disk are configured to achieve stable tool clamping.

The electrical cabinet is equipped with temperature regulator for cooling and heat dissipation to ensure normal operation of the electrical equipment.

The automatic lubrication device, with oil level display and fault alarm function, can effectively improve the service life of the machine tool by applying forced lubrication to the ball screw. The center frame and tail shaft bearings adopt independent oil and gas lubrication system to ensure good lubrication and prolong the service life of the center frame roller and tail shaft bearing.

The chip removal machine is a famous domestic brand, with auxiliary water tank and oil-water separation mechanism. The chip removal machine can work in automatic operation mode and manual operation mode to improve the service life of the chip removal machine.