Coal Picks, also known as miner picks, conical picks, or rock picks, are essential cutting tools used in the mining and tunneling industries. They are specifically designed to fracture and excavate materials like coal, soft rock, and other minerals by being mounted on rotating drums of continuous miners, roadheaders, and shearers.

Their primary function is to act as the point of attack, transferring the machine’s power into concentrated impact and shear force to break the material.

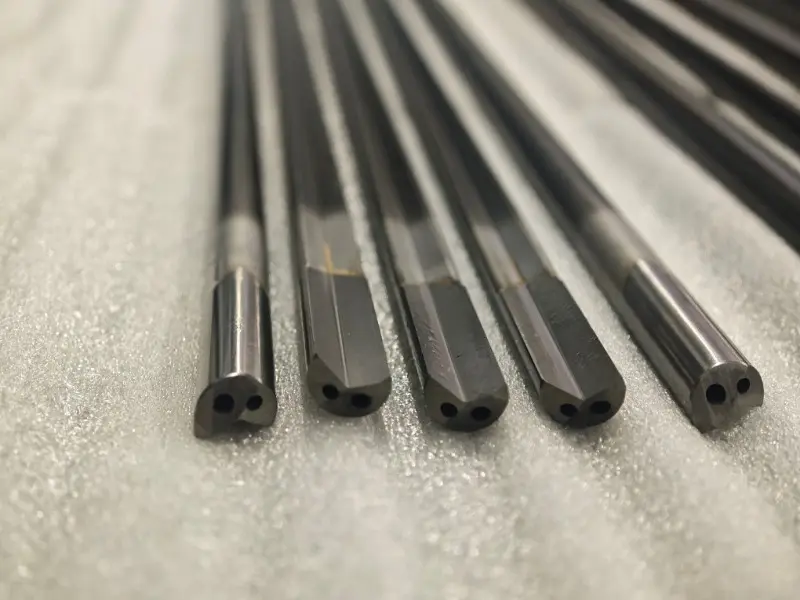

Tungsten Carbide Tip: The cutting tip is made of tungsten carbide, known for its superior hardness and wear resistance. This is crucial for cutting through abrasive materials. The tip is brazed onto a steel body.

Steel Body/Shank: The body is made of high-quality, tough alloy steel that can withstand significant impact loads and bending forces without breaking. The shank is precision-machined to fit securely into a block or holder on the machine's drum.

Conical/Chisel Shape: Coal picks typically have a pointed (conical) or chisel-shaped head. This design allows them to penetrate and fracture the material efficiently, creating chips rather than just grinding it to dust.

Retention System: They are held in place by a mechanical retention system, usually a ceramic button and spring clip or a similar locking mechanism. This system keeps the pick securely in the block while allowing it to rotate during operation.

Similar to carbide ball teeth, the efficiency and longevity of many coal picks rely on their ability to rotate:

As the drum rotates, the pick strikes and penetrates the coal face or rock.

The asymmetric forces acting on the conical tip cause it to rotate slightly in its holder with each impact.

This rotation ensures that wear is distributed evenly around the carbide tip, preventing the formation of a single flat spot. This "self-sharpening" effect maintains a sharp cutting profile and significantly extends the pick's service life.

Coal picks are fundamental tools in various excavation and mining operations:

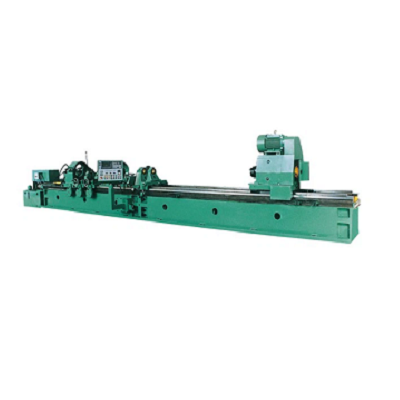

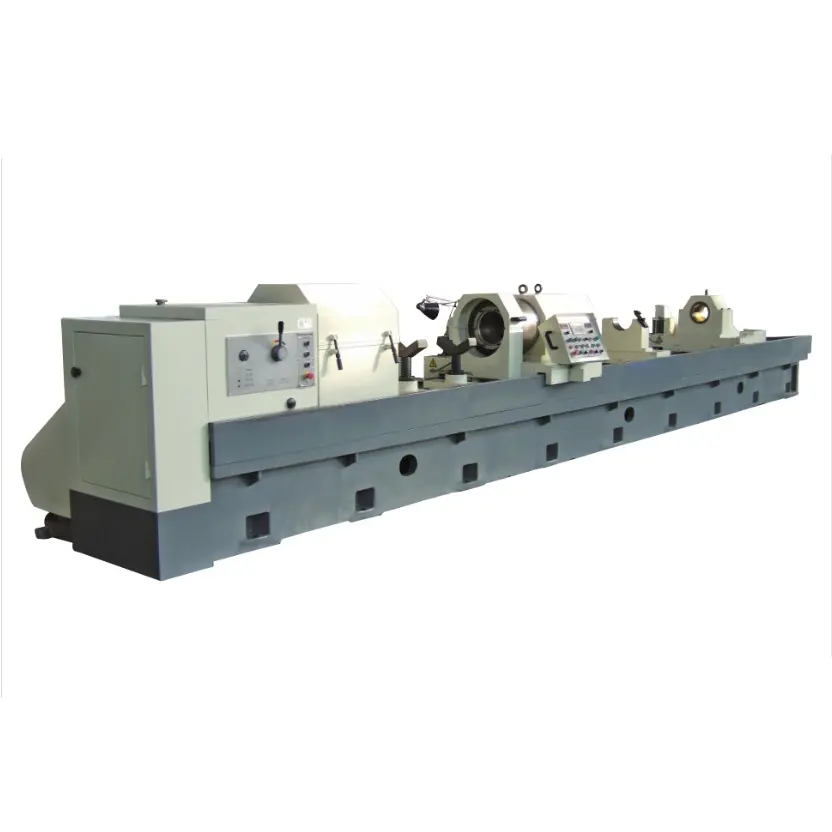

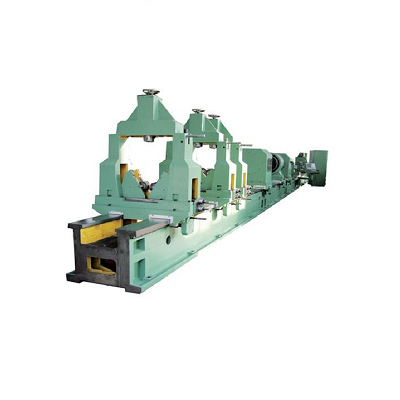

Underground Coal Mining: The primary application, used on continuous miners, longwall shearers, and roadheaders.

Tunnel Boring & Drifting: Used in soft to medium-hard rock tunneling and mine development.

Trenching & Surface Excavation: Employed on smaller trenchers and excavators for cutting through consolidated soils and soft rock.

The following table summarizes the key features for a quick overview:

| Feature | Description | Advantage |

| Head Shape | Pointed (conical) or chisel-shaped. | Efficiently penetrates and fractures material. |

| Material | Tungsten carbide tip brazed onto a tough steel body. | Combines extreme wear resistance with impact toughness. |

| Core Mechanism | Free rotation within a locked holder (for most types). | Promotes even wear, self-sharpening, and longer service life. |

| Primary Function | Fracture and excavate coal and soft to medium-hard rock. | Highly efficient for rapid material removal in mining. |

| Key Benefit | Increased Production Efficiency & Reduced Downtime. | Maintains cutting performance, reducing the frequency of replacement. |

| Common Applications | Continuous miners, shearers, roadheaders, tunneling machines. | The standard cutting tool for modern mechanical mining. |

In summary, Coal Picks are critical consumable components in the mining industry. Their robust design, combining a hard tungsten carbide tip with a tough steel body and a rotation mechanism, ensures high productivity and operational efficiency in challenging underground and surface environments.