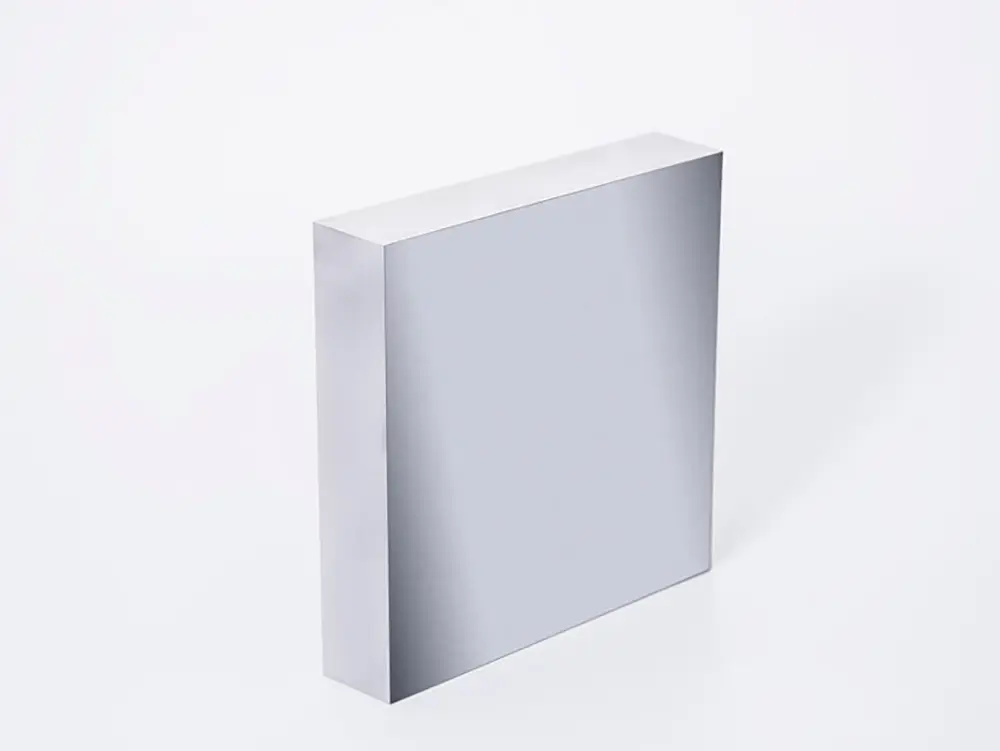

A Composite Sheet Substrate refers to a base material, typically in sheet form, that is composed of two or more distinct physical or chemical phases combined to create a new material with superior properties compared to its individual components. In advanced industrial contexts, this often involves combining a tough, ductile matrix (like a metal or polymer) with a hard, reinforcing phase (like ceramic particles or fibers) to achieve a balance of strength, toughness, and other specific functional properties.

These substrates are engineered to serve as a foundational platform for further processing or as a core structural component in demanding applications.

Tailored Properties: The primary advantage is the ability to design a material with a specific set of properties not found in a single material. This includes optimizing for:

High Strength-to-Weight Ratio: Especially in polymer or metal matrix composites reinforced with carbon or ceramic fibers.

Enhanced Wear Resistance: Achieved by embedding hard particles like tungsten carbide or ceramic into a metal matrix.

Improved Thermal or Electrical Conductivity: By incorporating conductive fibers or particles.

Controlled Thermal Expansion: Critical in electronics to match the expansion of semiconductors.

Multi-Functionality: A single composite sheet can be designed to perform multiple roles, such as providing structural support, wear resistance, and thermal management simultaneously.

Anisotropy: Properties can be engineered to be directional (anisotropic), such as being strong in one direction due to aligned fibers, which is ideal for specific load-bearing applications.

The "composite sheet substrate" is a broad category. Key types include:

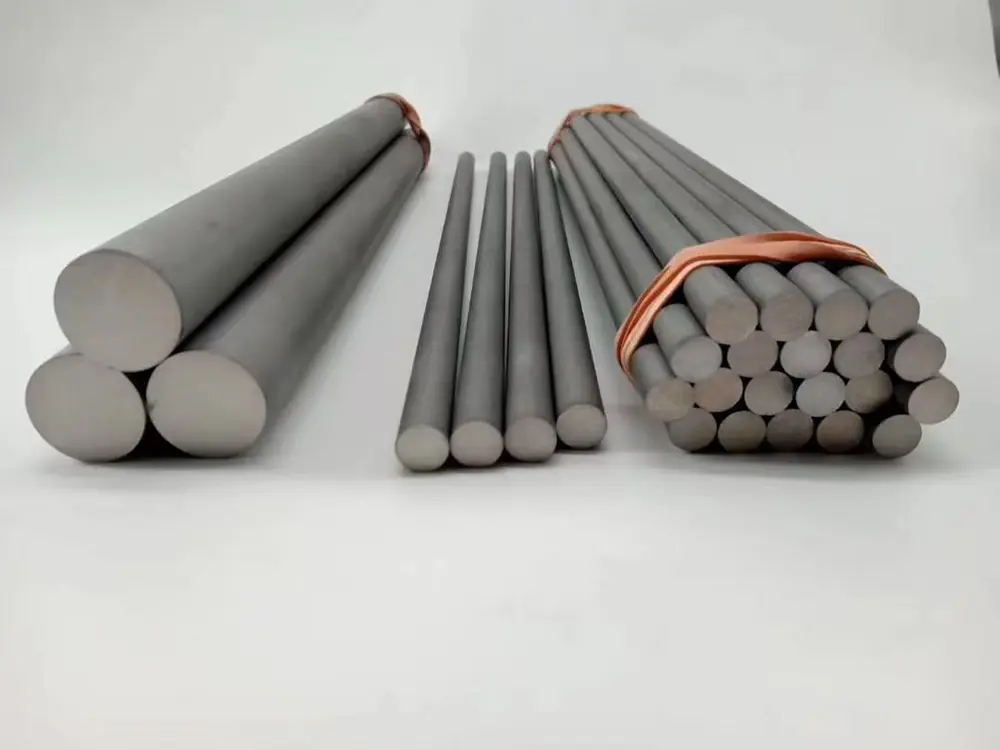

Metal Matrix Composites (MMC): A metal base (e.g., aluminum, copper) reinforced with ceramic particles (e.g., silicon carbide, boron carbide) or fibers.

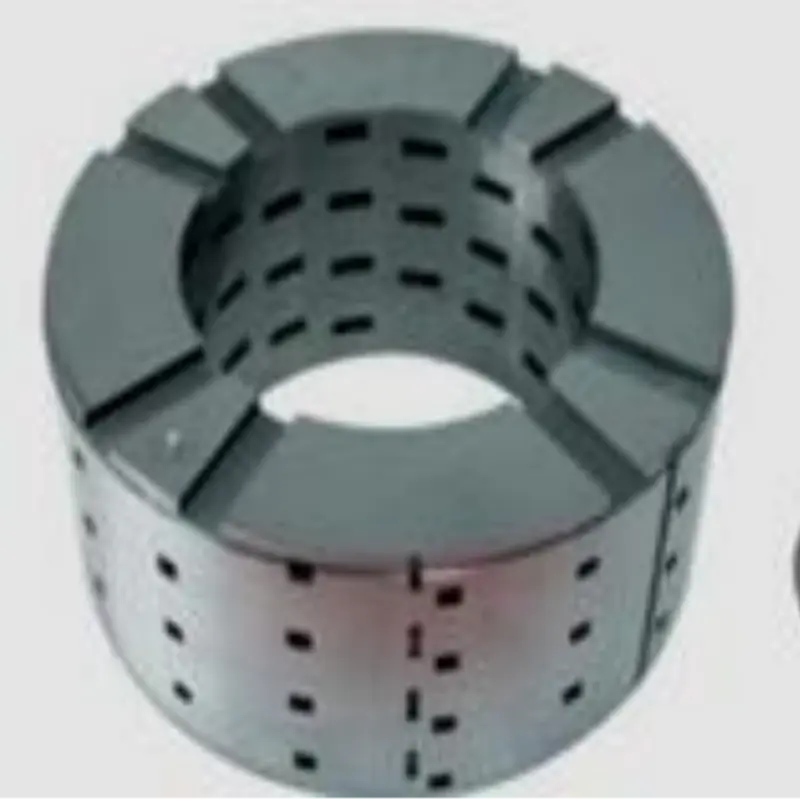

Ceramic Matrix Composites (CMC): A ceramic matrix (e.g., silicon carbide) reinforced with ceramic fibers, providing exceptional high-temperature strength and fracture toughness compared to monolithic ceramics.

Polymer Matrix Composites (PMC): A polymer resin (e.g., epoxy) reinforced with continuous fibers (e.g., carbon, glass, aramid). These are the classic "composite" sheets used in aerospace and sporting goods.

Laminated Composites: Multiple layers of different materials (e.g., metals, polymers) are bonded together to create a sheet with properties derived from each layer.

Composite sheet substrates are foundational in high-tech industries:

Electronics Packaging: Used as substrates for semiconductor chips and circuits. Examples include:

Direct Bonded Copper (DBC): A ceramic sheet (like Al₂O₃ or AlN) with copper bonded to both sides, used for power modules.

Metal Core PCBs: A metal base (like aluminum) with a dielectric layer and circuit layer, used for LED lighting.

Aerospace & Defense: As structural panels for aircraft skins, satellite components, and armor systems, where lightweight and high strength are critical.

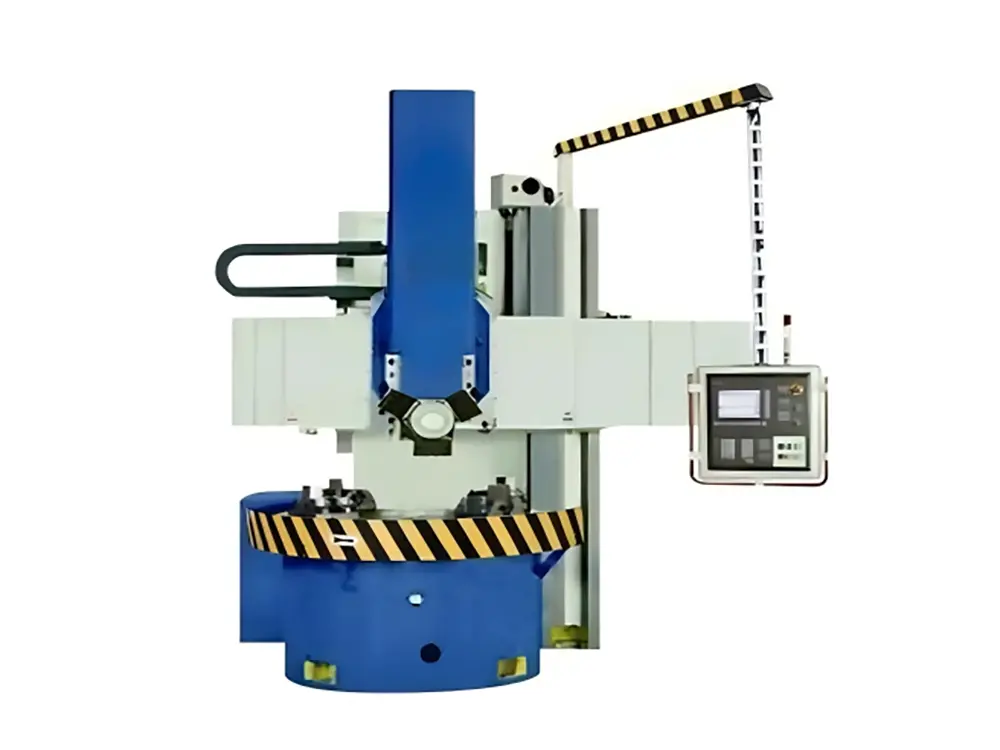

Wear-Resistant Liners: MMC sheets containing tungsten carbide or other hard phases are used to line equipment in mining, agriculture, and material handling.

Thermal Management: As heat sinks or spreaders in high-power electronics, leveraging composites with high thermal conductivity (e.g., Al-SiC).

The following table summarizes the key features for a quick overview:

| Feature | Description | Advantage |

| Core Concept | A base sheet made by combining two or more different materials. | Enables creation of materials with property combinations impossible for a single material. |

| Key Principle | Synergy. The matrix and reinforcement work together to create superior properties. | Achieves an optimal balance, e.g., toughness from the matrix and hardness from the reinforcement. |

| Common Reinforcements | Particles (Carbide, Ceramic), Fibers (Carbon, Glass). | Imparts specific properties like wear resistance or high strength. |

| Common Matrices | Metals (Al, Cu), Polymers (Epoxy), Ceramics (SiC). | Provides the continuous phase, offering toughness, and binding the reinforcement. |

| Primary Driver | Performance and Functionality. | Allows for lightweight, efficient, and durable designs in advanced engineering. |

| Key Industries | Electronics, Aerospace, Automotive, Defense, High-end Manufacturing. | The enabling material for technological advancement in these sectors. |

In summary, a Composite Sheet Substrate is a highly engineered foundational material. It is not a simple raw material but a sophisticated platform designed from the atomic level up to provide specific mechanical, thermal, and electrical properties, making it indispensable for modern high-performance applications.