Model: DHB-T Series (Customizable)

Brand:DRILLSTAR

Origin: China

| Parameter | Details |

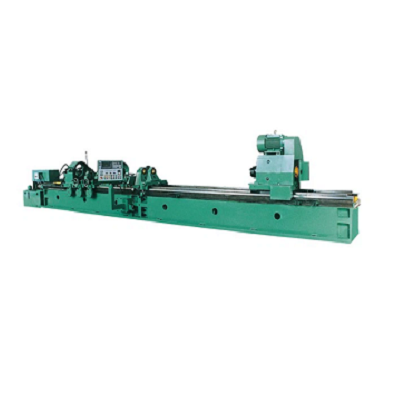

| Boring Diameter Range | φ30 mm ~ φ800 mm (customizable for φ10 mm ~ φ1000 mm) |

| Depth-to-Diameter Ratio | Up to 120:1 (standard: 20:1 ~ 80:1; max. machining depth: 12 meters) |

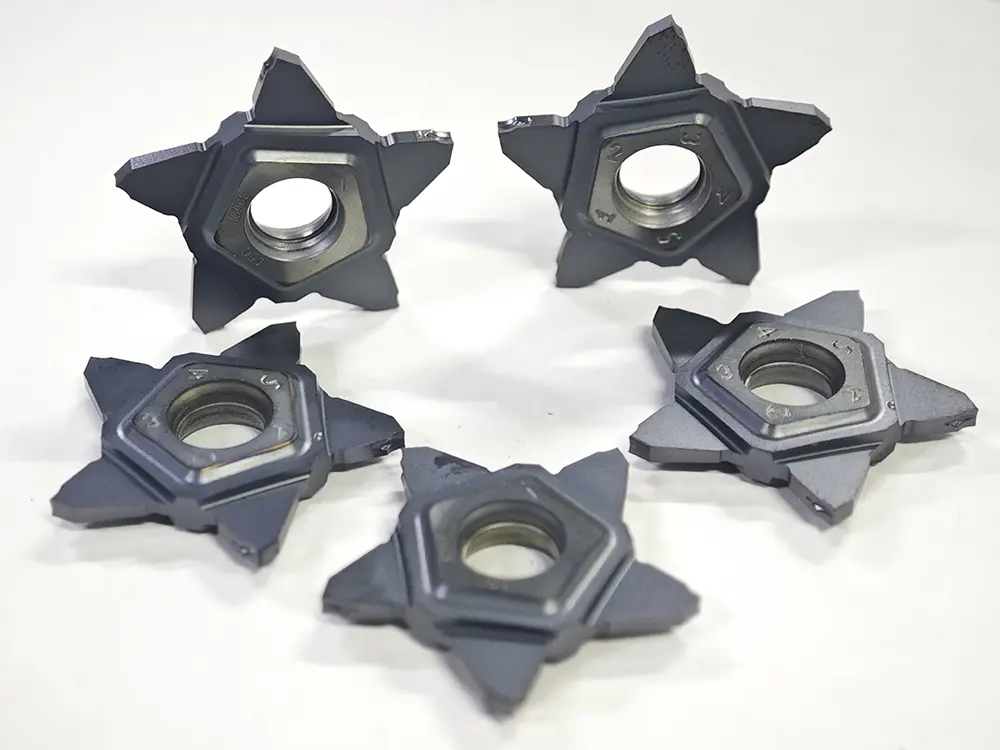

| Tool Material | Ultra-fine grain carbide (Kennametal 2210) + AlCrN/TiAlN coating |

| Shank Type | Modular design (interchangeable base shank, extender; compatible with HSK/SK/Capto interfaces) |

| Cooling System | Internal through-tool coolant (1–2 MPa pressure) + external chip evacuation |

| Tolerance | Hole diameter: IT7 ~ IT9; Straightness: 0.05 mm/1000 mm |

| Surface Roughness | Ra 0.4 ~ Ra 1.6 μm (achievable on finished bores) |

| Cutting Parameters | - Cutting speed (Vc): 15–20 m/min (steel); 30–60 m/min (aluminum)- Feed rate (f): 0.12–0.2 mm/rev (finish boring) |

| Tool Geometry | - Rake angle (γ₀): 10°–15°- Clearance angle (α₀): 6°–8°- Lead angle (κᵣ): 45°–65° |

This tool is engineered for high-precision deep-hole machining in:

1.Hydraulics & Heavy Machinery: Hydraulic cylinder bores (2–12m length), gearbox housings.

2.Aerospace & Defense: Titanium alloy components, missile/weapon barrel bores (IT7 tolerance).

3.Energy Equipment: Nuclear reactor pressure vessel guide tubes, turbine rotor bores.

4.Automotive: Engine cylinder liners, transmission case deep bores.

5.Mold & Die: Cooling channels in large plastic injection molds (φ50–φ200 mm bores).

1、Superior Stability & Vibration Control

1:1000 Tapered Shank Design: Minimizes cutting vibration even at extreme depth ratios.

Welded Carbide Guide Pads (2–4 pads): Ensures consistent bore straightness and roundness (0.05mm/1000mm straightness).

2、Efficient Chip Management

Internal Coolant Delivery: Flushes chips directly from the cutting zone, avoiding clogging (critical for deep bores).

Optimized Chip Breaker: Breaks swarf into small segments, reducing re-cutting and tool wear.

3、Precision & Adjustability

Micron-Level Adjustment Mechanism: Radial adjustment screw compensates for errors (±0.02mm), ensuring tight diameter tolerance (IT7).

Modular Assembly: Interchangeable components adapt to different bore sizes/depths, reducing tool inventory costs.

4、Durability & Cost-Effectiveness

Ultra-Fine Grain Carbide + Coating: Extends tool life by 30% vs. standard carbide (resists wear in high-temperature machining).

Indexable Insert Design: Replaceable cutting edges eliminate full tool replacement, lowering operating costs.

5、High Load Capacity

Adhesive-Bonded Tool Joint: Withstands 200N cutting force (14kg/cm² bonding strength), suitable for heavy-duty boring.

6、Packaging & Service

Packaging: Sealed moisture-proof box + wooden crate (for large tools).

Service: Free technical consultation (cutting parameter optimization), 12-month warranty, customizable tool design.