Model: Customizable (e.g., DHF-XX Series)

Brand: DRILLSTAR

Origin: China

| Parameter | Details |

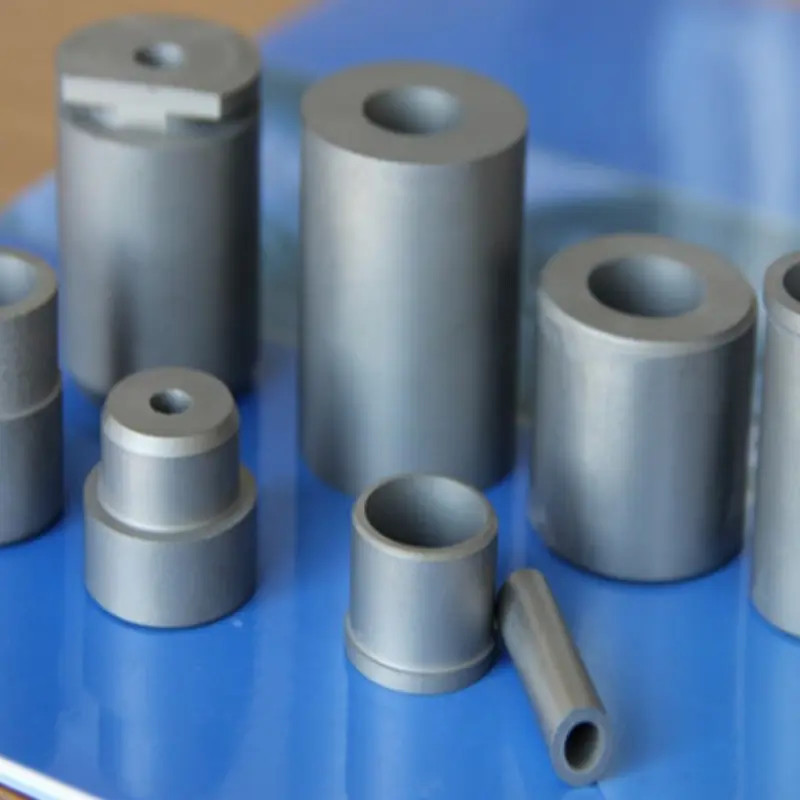

| Diameter Range | φ5 mm ~ φ100 mm (customizable for larger/smaller sizes) |

| Depth-to-Diameter Ratio | Up to 400:1 (standard: 20:1 ~ 250:1) |

| Tool Material | Cemented carbide (WC-Co), coated with AlCrN/TiAlN (wear-resistant) |

| Shank Type | Straight shank, Morse taper, or custom (compatible with CNC/ gun drill machines) |

| Cooling Mode | Internal coolant delivery (through-tool) + external chip evacuation |

| Tolerance | Hole diameter: IT6 ~ IT8; Straightness: 0.16 ~ 0.33 mm/1000 mm |

| Surface Roughness | Ra 0.1 ~ Ra 3.2 μm (achievable on finished holes) |

| Cutting Speed (Vc) | 30 ~ 150 m/min (varies by workpiece material) |

| Feed Rate (f) | 0.04 ~ 0.16 mm/rev (optimized for chip control) |

| Applicable Materials | Carbon steel, alloy steel, stainless steel, cast iron, aluminum, etc. |

This tool is widely used in high-precision manufacturing scenarios requiring deep, complex holes:

1.Automotive & Diesel: Fuel rails, injectors, precision shafts, engine blocks.

2.Aerospace & Defense: Lightweight structural parts, turbine components, weapon barrels.

3.Mold & Die: Cooling channels in plastic/rubber injection molds, die-casting molds.

4.Medical Devices: Implants, surgical instrument components (micro-diameter holes).

5.General Machinery: Hydraulic cylinders, heat exchanger tube sheets, gearboxes.

1.High Precision & Stability

Special cutting edge geometry + optimized guide pads ensureexcellent roundness, straightness, and hole position accuracy (critical for deep-hole machining).

Rigid carbide body minimizes vibration, avoiding tool breakage even at high depth ratios.

2.Efficient Chip Control & Evacuation

Unique chip breaker + internal coolant design (1–2 MPa pressure) enables smooth chip removal, preventing chip jamming and tool wear.

Chips are broken into small segments (no long, tangled swarf), improving safety and process continuity.

3.Cost-Effective & Durable

Indexable insert design (replaceable cutting edges) reduces tool replacement costs (no need to discard the entire tool when edges wear).

Multilayer AlCrN coating providessuperior wear resistance (tool life up to 6,000 holes for standard materials).

4.Versatility & Customization

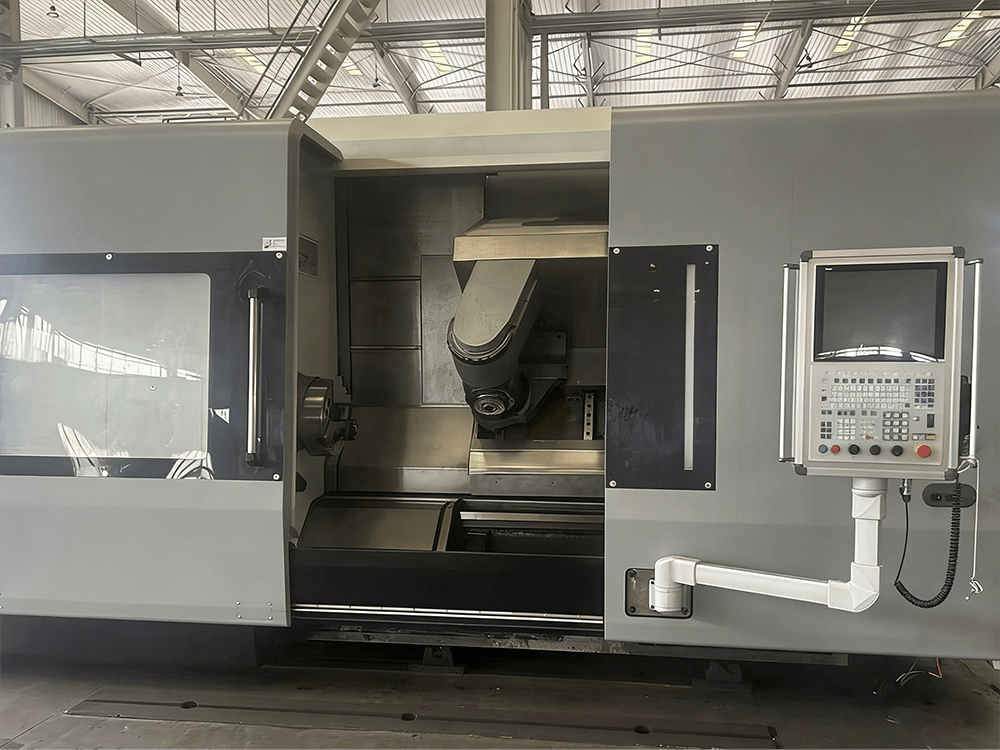

Compatible with gun drill machines, CNC machining centers, and 5-axis lathes.

Customizable diameter, depth ratio, and shank type to match specific workpiece requirements.

5.One-Pass Machining

Integrates drilling, boring, and reaming into a single operation,reducing cycle time by 50%+ compared to traditional multi-step processes.

6.Packaging & Service

Packaging: Sealed plastic box + carton (moisture-proof, shock-resistant).

Service: Free sample (for bulk orders), technical support for cutting parameter optimization, 12-month warranty.