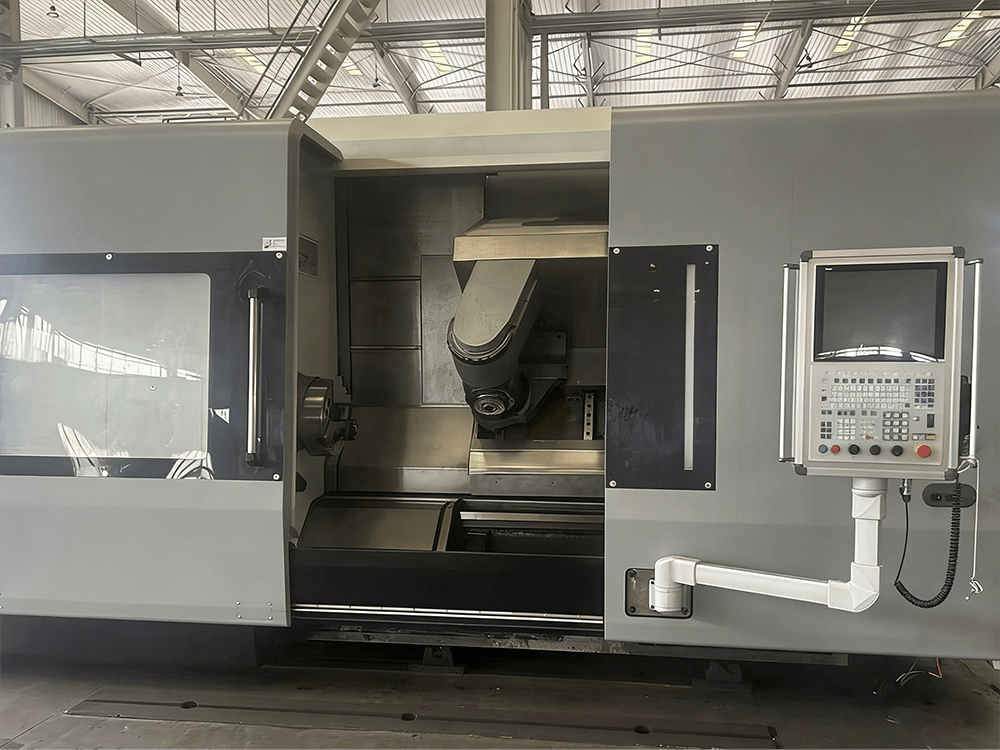

Machining accuracy meausre of skewness: 1mm/1000mm(workpiece is not rorate) 0.5mm/1000mm(the workpiece rotate, drilling coaxial hole, bar type workpiece) roughness:8~6.3um accurancy: H7~H11 Roundness: ≤0.008 Machine brief Gundrilling range:Φ3~Φ20mm/Φ3~Φ30mm/Φ6~Φ40mm Gundri...

meausre of skewness:

1mm/1000mm(workpiece is not rorate)

0.5mm/1000mm(the workpiece rotate, drilling coaxial hole, bar type workpiece)

roughness:8~6.3um

accurancy: H7~H11

Roundness: ≤0.008

Gundrilling range:Φ3~Φ20mm/Φ3~Φ30mm/Φ6~Φ40mm

Gundrilling maximum depth:500/1000/1500/2000/2500 mm

Hole maximum length and diameter ratio: 100:1

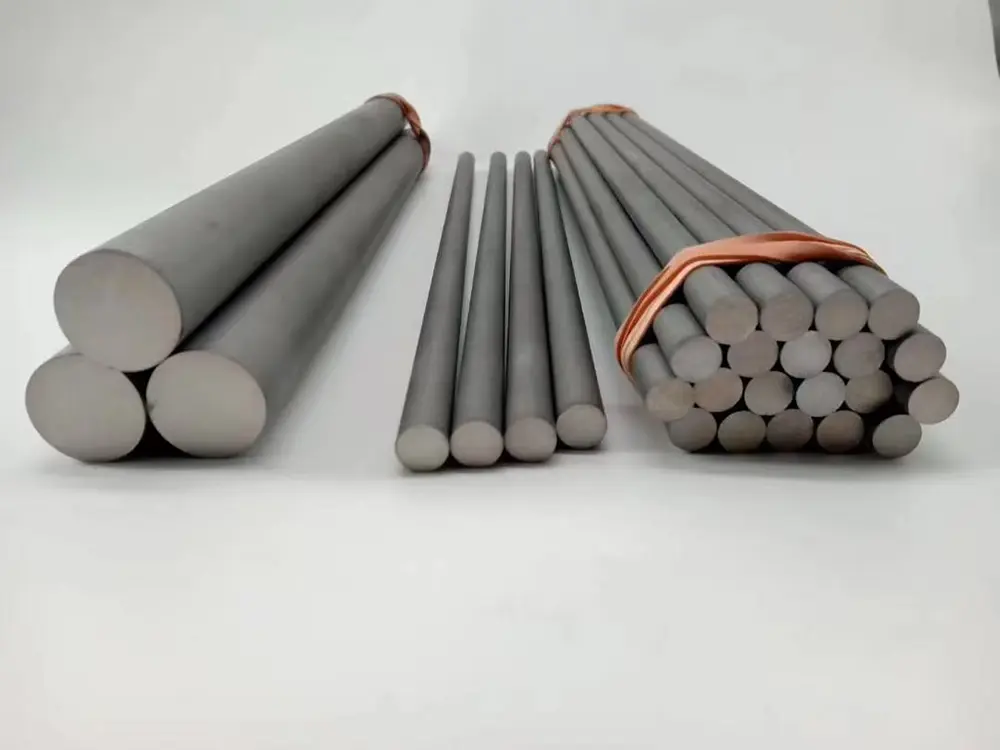

OD job range: :Φ15~Φ100mm

Gundrilling method:double spindle,suitable for shaft or round bar job. Headstock:drive the job rotating,consistant speed 117r/min

Guide rail adopts linear guide rail

CNC controller system: SIEMENS/FANUC/GSK

Guide rail adopts linear guide rail

CNC controller system: SIEMENS/FANUC/GSK

| Model | ZK2102 series | ZK2103 Series | ZSK2104 Series | |||

| Double spindle | Double spindle | Double spindle | ||||

| Hole drilling diameter range | 4mm-20mm | 4mm-30mm | 6mm-40mm | |||

| Max.gun drilling length | 500/1000/1500/2000/2500mm | |||||

| Mainly parameters | Main spindle quantity | 2 | ||||

| Main spindle space | 140mm | |||||

| Drill box | Main motor power | 7.5kw | 11kw | 15kw | ||

| Maxiumum rotating speed | 5000r/min | 3500r/min | ||||

| Headstock | power | 1.5w | ||||

| Rotating speed | 120r/min | |||||

| Tool infeeding | Infeed speed range | 5-500mm/min | ||||

| Rapid speed | 4m/min | |||||

| Infeed motor torque | 7.5Nm | 10Nm | ||||

| Coolant system | Maxiumum flow | 100L/min | 150L/min | 200L/min | ||

| Maximum pressure | 10Mpa | 8Mpa | ||||

| Filtering accuracy | 20um | |||||

| Hole size accuracy | IT7-IT10 | |||||

| Processing accuracy | Hole roughness | Ra0.8um-Ra3.2um | ||||

| Hole deviation | Job fixed: 1mm/1000mm,Job ratating :0.5mm/1000mm. | |||||

| General power | Machine general power | 25kw | 33kw | 42kw | ||

Feed system is controlled by the Simens computer controlled system, and equipped with the AC servo motor, infinite speed variation, feed speed range: 10-500mm/min. Feed moving table is Three surface closed and Triangular stiffener, so the feed system has high accuracty, good stiffnes, smooth movement, and good maintainess of accuracy, etc.

The upside of the oil tank is equipped with oil pump, motor and hydraulic components. A motor drives a gear pump in the cooling system. The max flow is app. 100L/min. The oil supply pressure is adjusted by the overflow valve, and showed by the electric connecting pressure gauge. The coolant of cutting oil is automatically controlled by the automatic oil temperature control tank. The Iron chips are automatically delivered to the dust storing the car through the scraps discharge machine. The cooling oil is filtered by the non-woven fabrics paper characteristics filter, meshy filter, or magnetic filter.

The lubrication of main relative motion surface of the machine is supplied by the centralized lubrication device time and mensurable.

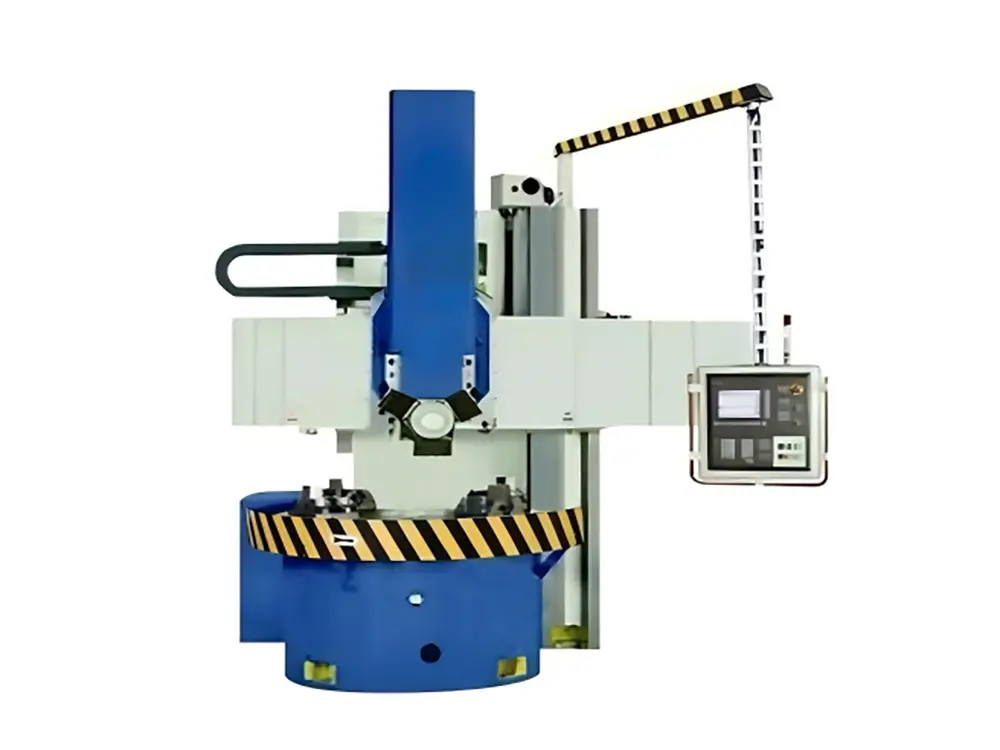

The hydraulic system supplies the hydraulic oil to the cylinder which controls the headstock spindle movement, and cooperate with the electric control system, and Top tight, loose the workpiece by the procession steps.

Feed system is controlled by the Simens computer controlled system, and equipped with the AC servo motor. It can complete Automatic processing cycle by program setting, and can adjust manually, pointing control, and on and off.

Guide frame is to guide the gun drills, support the shank, and remove the chip.

Bracket is to support the workpiece and pre position. It can move freely on the T type working table, and is adjusted according to the work piece size.

Drilling pile bracket: Its function is to support and absorb the shock.

The machine all around and top is protected closely.

This machine bed body is robust cast iron. Drilling pipe box, bracket, headstock are integral structure.

This machine is dedicated deep hole drilling machine, high efficiency, high accuracy, high automation. It is outside chip removal. It can meet the accuracy and surface roughness by one time drilling, instead of drilling, enlarging, and reaming.

Hydraulic cone disc presses against the 60° reverse angle chamfer on the both ends of the work pieces. The workpiece is pre positioned by the braket, then pressed against the headstock, then positioned by the dual cones. When working, the workpiece rotates reversed, and the cutting tool rotates and feeds.