Wear-Resistant Alloys are a class of materials specifically engineered to withstand surface degradation and material loss caused by mechanical wear. This wear can result from abrasion (scraping), erosion (impact by particles), adhesion (galling and seizing), and impact.

Their primary function is to extend the service life of industrial equipment, reduce downtime, and improve operational efficiency in demanding environments.

The Science of Wear Resistance

Wear resistance is not a single material property like density; it's a complex system behavior. The key to a material's wear resistance lies in its ability to resist plastic deformation and fracture. This is primarily achieved through:

High Hardness: Resists penetration and abrasion by hard particles.

Work Hardening: The ability to become harder and tougher at the surface when impacted or stressed (e.g., Hadfield manganese steel).

Toughness: Resists chipping, cracking, and spalling under impact loads.

Microstructure: The presence of hard carbides (e.g., chromium, tungsten, vanadium carbides) embedded in a tough metallic matrix is a common feature.

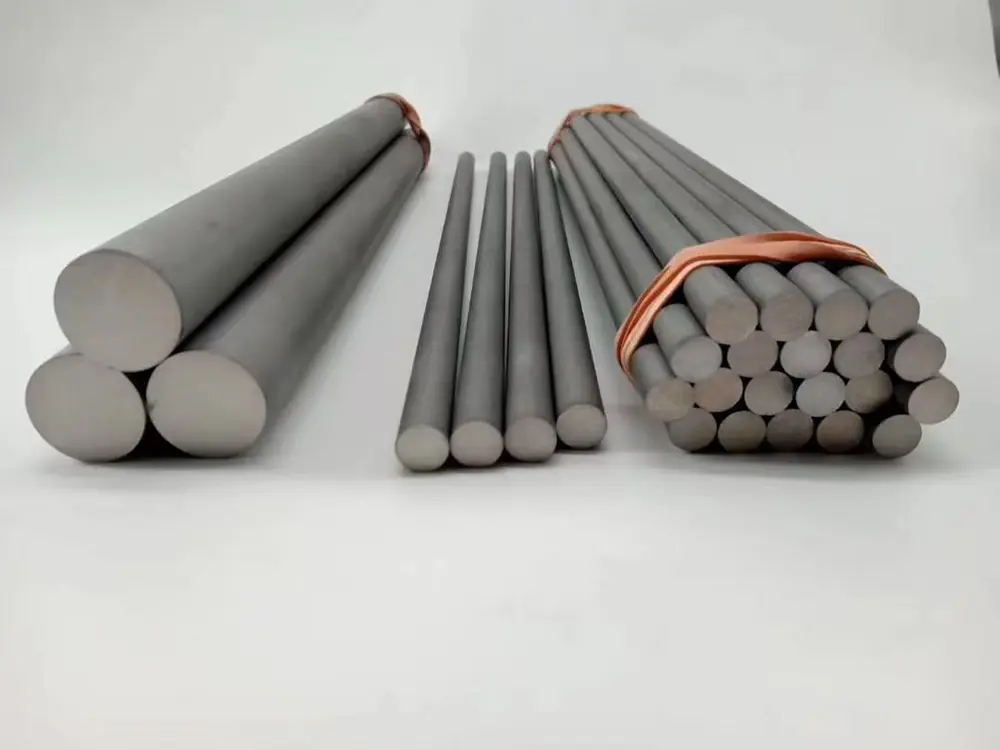

Wear-resistant alloys are typically based on ferrous metals (iron and steel) or non-ferrous metals, each tailored for specific wear mechanisms.

| Alloy Type / Base | Key Characteristics | Common Grades / Examples | Primary Applications |

| Martensitic Steels | High hardness and good strength; achieved through heat treatment (quenching & tempering). | AR400, AR500, 4140, 4340 | Mining buckets, crusher liners, bulldozer blades, wear plates. |

| Austenitic Manganese Steel | "Hadfield Steel". Extremely tough and work-hardening. Upon impact, its surface hardness increases dramatically while the core remains tough. | A128 Grade C, MN13, MN18 | Jaw crusher liners, railroad frogs, rock drill bits, crawler tracks. |

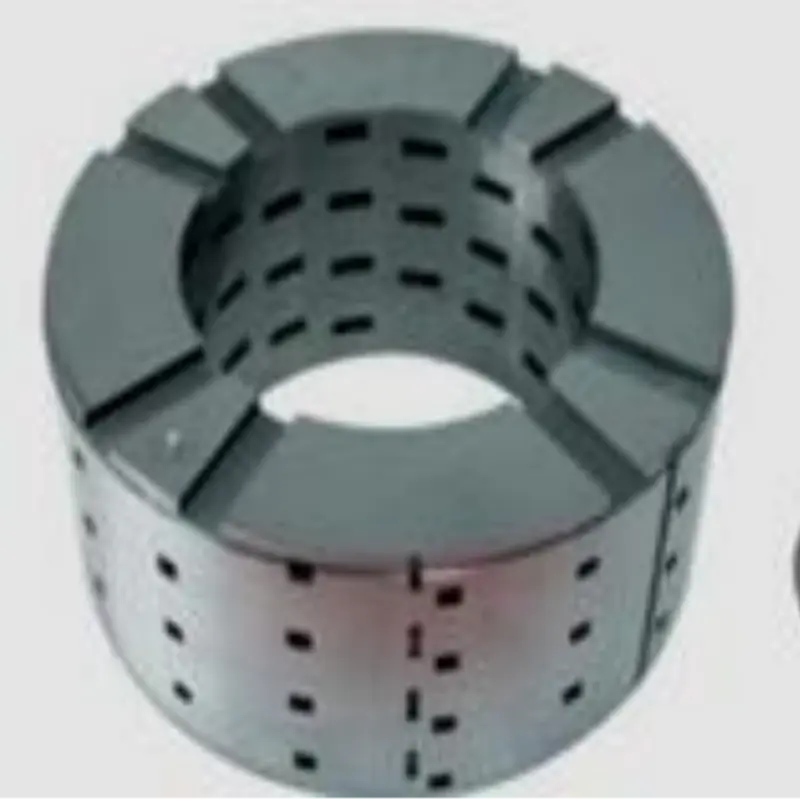

| High-Chromium White Cast Iron | Exceptional abrasion resistance due to a high volume of hard chromium carbides. Can be brittle under impact. | Ni-Hard, A532 | Slurry pump casings, mill liners, pulverizer rolls, shot blasting equipment. |

| Carbide Composites | Not a monolithic alloy, but a critical wear-resistant material. Hard tungsten carbide particles embedded in a tough metal matrix (like cobalt or nickel). | Tungsten Carbide-Composites, Stellite (Cobalt-based) | Hardfacing wires, wear plates, cutting tools, drill bits, valve seats. |

| Cobalt-Based Alloys | Excellent resistance to a combination of wear, corrosion, and high temperatures (red-hardness). | Stellite, Haynes alloys | Gas turbine blades, high-temperature valves, saw tips, engine components. |

| Nickel-Based Alloys | Similar to cobalt alloys, offering good wear and corrosion resistance, often used where cobalt is not suitable. | Inconel, Colmonoy | Chemical processing equipment, aerospace components, hardfacing overlays. |

These alloys are not always used to make entire components. They are often applied in cost-effective ways to protect a base material:

Cast Components: The part (like a pump casing) is entirely cast from the wear-resistant alloy.

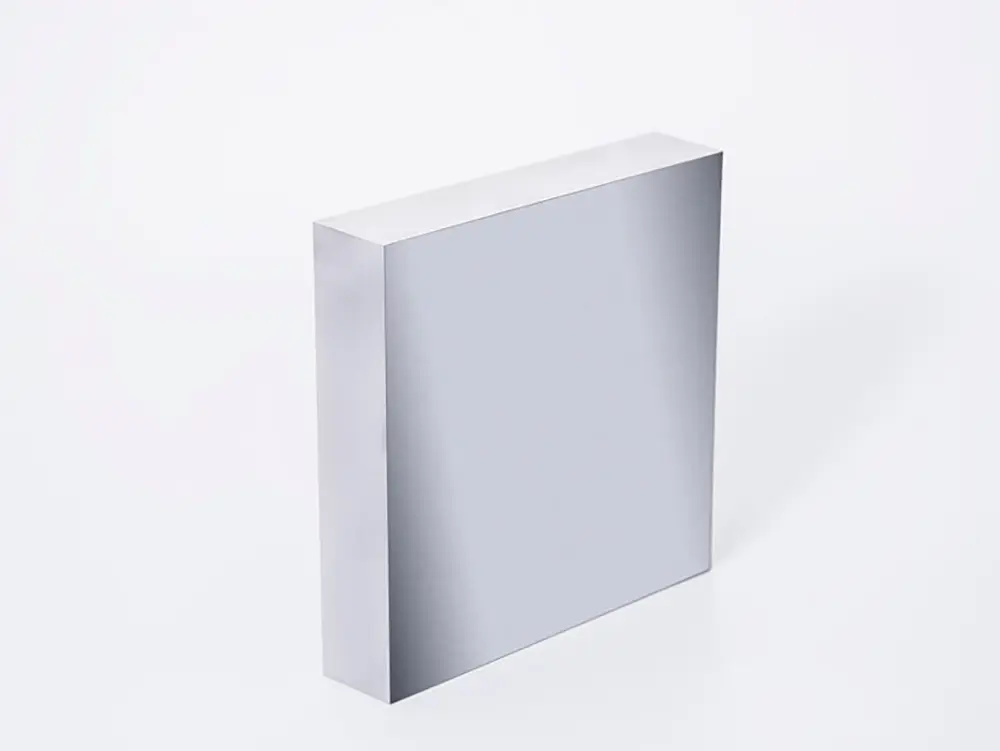

Wear Plates: Sheets of hardened steel (e.g., AR400) are bolted or welded onto vulnerable surfaces.

Hardfacing / Cladding: A layer of wear-resistant alloy is welded or fused onto the surface of a cheaper, tougher base metal. This is a very common and economical method.

Thermal Spray: A coating of the alloy is sprayed onto the surface to create a wear-resistant layer.

In summary, Wear-Resistant Alloys are a diverse and critical family of materials that form the backbone of heavy industry. The selection of the appropriate alloy depends on a precise understanding of the wear mechanism (abrasion, impact, etc.), the operating environment (including temperature and corrosion), and economic considerations.