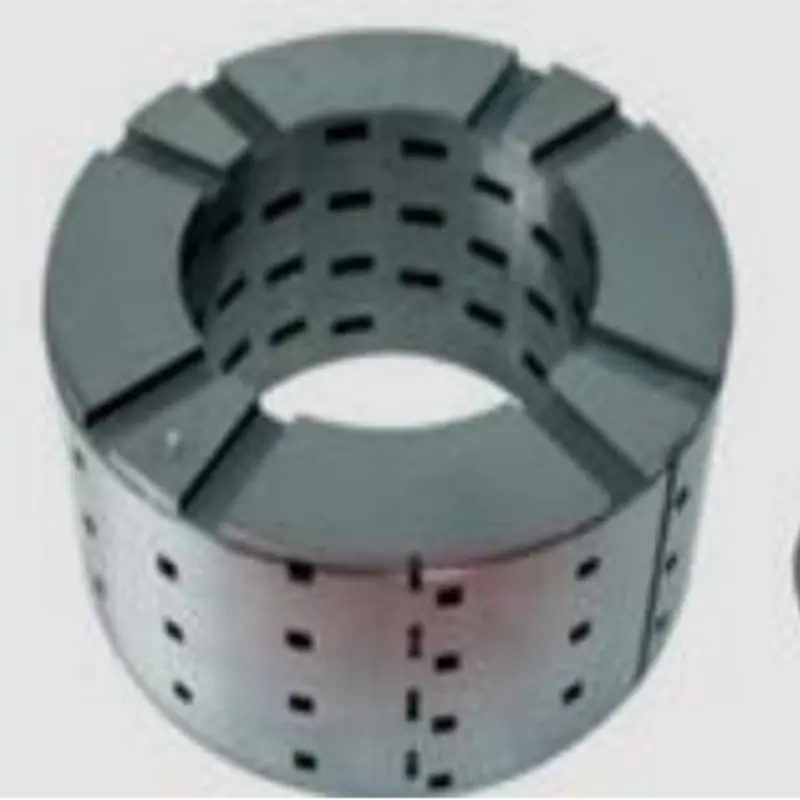

Core Definition and Structure Grooving inserts are preformed replaceable cutting units, generally rectangular, square, or special-shaped (e.g., comma-shaped) in overall form. The cutting edges are designed as single-edged or double-edged, with chip breaker grooves or straight-edge struc...

Grooving inserts are preformed replaceable cutting units, generally rectangular, square, or special-shaped (e.g., comma-shaped) in overall form. The cutting edges are designed as single-edged or double-edged, with chip breaker grooves or straight-edge structures, and the bottom features positioning holes or positioning grooves (compatible with tool holder clamping mechanisms). The primary material of grooving inserts is cemented carbide; some high-end models adopt PCD (Polycrystalline Diamond) or CBN (Cubic Boron Nitride), and the surface may be coated with TiAlN, TiCN, Al₂O₃, or other coatings. They are fixed to tool holders via brazing or mechanical clamping to achieve groove cutting.

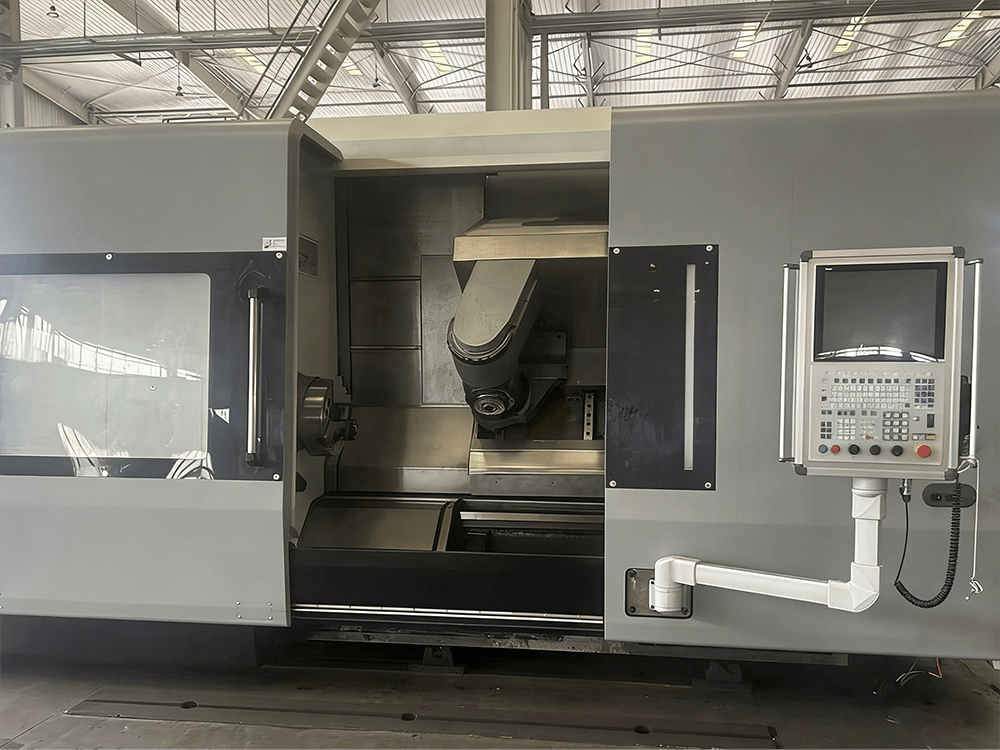

Typical Machining Objects:

Seal grooves, oil grooves, and relief grooves on the outer circle of shaft parts;Control grooves and seal grooves on the inner hole of hydraulic valve blocks;Annular grooves and positioning grooves on the end face of flange plates;Pipe cutting grooves (grooving inserts are also used as parting inserts).

Process Advantages:

Indexable design: After cutting edge wear, the insert can be directly rotated or replaced without regrinding, improving machining efficiency;Precise groove width: The tolerance of preformed cutting edge width is ≤±0.01mm, meeting the dimensional requirements of precision grooves;High versatility: The same tool holder can be compatible with inserts of different groove widths and materials, reducing tool costs;Controllable chip breaking: Inserts with chip breaker grooves can effectively control chips and avoid chip entanglement.