1.Equipment model: LK2120-5000

2. Rated tension: 150kN

3. Maximum stroke: 5000mm

4.Equipment use: The equipment is used to process variable lead and non-variable lead internal spirals, as well as linear grooves, and is suitable for processing products with equal wall thickness stators

| Technical specification | Parameter | Remarks | ||||

| Work range | hole inner diameter | Φ5~Φ30mm | ||||

| hole max depth | 2000mm | |||||

| Machine function | X-axis | Feed rate | 5~500mm/min | endless | ||

| Rapid travel rate | 10000mm/min | |||||

| Motor torque | 15Nm | |||||

| C-axis | Rapid travel rate | 3000mm/min | ||||

| Motor torque | 6Nm | |||||

| Positioning accuracy/ Re-Positioning accuracy | 0.02mm | |||||

| Distance of travel | 360 degree | |||||

| Y-axis | Motor torque | 15Nm | ||||

| Positioning accuracy/ Re-Positioning accuracy | 0.03mm/0.02mm | |||||

| Machine overall power (appx.) | 13KW | |||||

| Floor space (length × width)Floor space (length × width) | 6500mm×2000mm | |||||

| Total weight of the machine (approx.) | 7 tons | |||||

| CNC system | KND system | |||||

| Cooling system | Maximum flow rate | 10L/min | adjustable | |||

This broaching machine adopts external removing Chip method.

This machine is suitable for column material,the workpiece is fixed and the tool is rotated to feed.

diameter:φ5mm~φ30mm

Max hole depth:2000mm

Workpiece outside diameter range: ~φ60mm

CNC system:KND system

Hole accuracy:IT7~IT11

(1) Install the workpiece to the dedicated chucks;

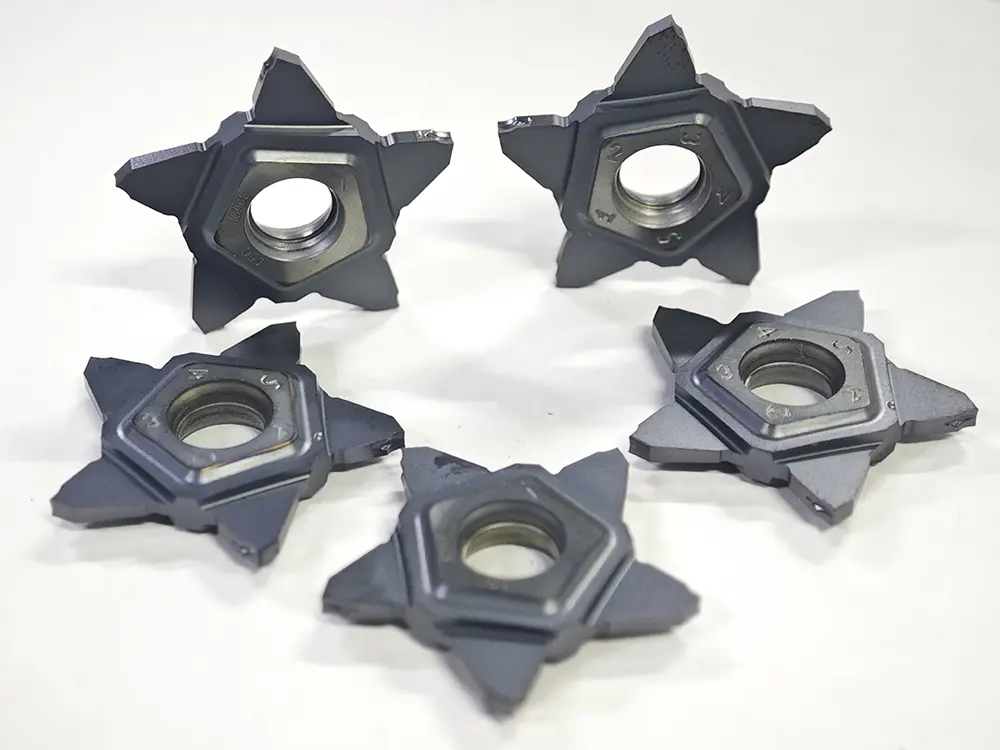

(2) Install the cutting tool to the tool holder;

(4) Open the cooling system;

(5) During machining, the tool feed is rotated by the system at a certain angle.

(6) Z axis feeding system drives the cutting tool to feed;

(7) When processing to a certain place, the cutting tool is adjusted to a certain height by the back-driving system;

(8) Z-axis driving system drives the cutting tool to back off, at the meantime, the cutting tool rotates with its angle, to complete a procession.

(9)The cutting tool returns to the most front of the workpiece with its original route, then the cutting tool rotates a certain angle.

(10)Repeat steps(5)--(9), and finish the whole procession of the workpiece.

- Material Selection: Generally, high-strength alloy steels such as 4145H and 35CrMo are used. These materials possess good strength, toughness, and fatigue resistance, enabling them to withstand the complex stresses encountered during drilling.

- Machining Processes: These include forging, which shapes the billet into a near-finished product, improving the material's internal structure and increasing strength; rough machining, using lathes, milling machines, etc., for preliminary machining of the outer diameter, end faces, and threads; deep hole machining, using deep hole drilling machines or gun drills to machine the center deep hole of the drill clip, ensuring the hole's straightness and dimensional accuracy; finish machining, precision machining of the drill clip's outer diameter, threads, etc., to improve dimensional accuracy and surface quality; heat treatment, through quenching and tempering, to improve the material's hardness, strength, and toughness; and surface treatment, such as hard chrome plating, to improve the drill clip's wear resistance and corrosion resistance.

- Quality Control: Rigorous non-destructive testing, such as ultrasonic testing and magnetic particle testing, is required to detect internal and surface defects. Strict measurement and control of the dimensional accuracy and geometric tolerances of the drill tip are essential to ensure compliance with design requirements. Performance tests, such as torque and tensile tests, are also necessary to guarantee the reliability of the drill tip in actual use.

In the era of machining that pursues ultimate precision and high-efficiency production, DrillStar deep hole broaching machines, with their superior product performance and innovative technology, have become a key tool for various industries to overcome machining bottlenecks! Our company can design different broaching machines for different workpiece sizes; models such as LK2102-2500 and LK2102-5000 are best-selling both domestically and internationally.

Micron-level precision machining, zero-error delivery

Equipped with imported servo motors and high-precision ball screws, DrillStar deep hole broaching machines achieve a positioning accuracy of ±0.005mm and a repeatability of ±0.002mm, perfectly suited for high-precision fields such as aerospace and optical instruments. Its unique constant temperature control system can control processing temperature fluctuations within ±1℃, effectively avoiding thermal deformation and ensuring a straightness of ≤0.01mm/m in deep hole machining, achieving a mirror-level internal hole surface roughness Ra0.8.

Superior Material Adaptability, Hard Material Conqueror

For difficult-to-machine materials such as titanium alloys and nickel-based superalloys, the equipment is equipped with a powerful broaching force system of up to 500kN, combined with independently developed coated broaching technology, increasing cutting efficiency by 40%. A patented vibration suppression device reduces tool wear by 60%, extending tool life by 2 times, making high-strength material machining no longer a challenge.

Fully Automated Intelligent Control, Worry-Free Production

Employing a new generation of intelligent CNC system, it supports 3D modeling programming and adaptive machining. The equipment has a built-in AI fault diagnosis function, which can monitor 12 core parameters such as tool wear and abnormal cutting forces in real time, providing early warnings of potential risks. An automatic chip removal system combined with a high-pressure coolant circulation device ensures continuous operation without jamming, increasing processing efficiency by 60% compared to traditional equipment.

Modular Customization, Flexible Adaptability

Supports a full range of machining sizes from 3-120mm in diameter and 1-5 meters in depth, allowing for rapid switching between different machining modes through modular components. Whether machining slender deep holes, stepped holes, or spiral grooves, the Drill Star deep hole broaching machine can easily handle the task, meeting the diverse needs of various industries such as military, automotive, and mold making.

Wide Applications, Empowering Industrial Upgrading

Aerospace: In the high-precision aerospace field, the machining accuracy of parts is crucial to flight safety and performance. With micron-level positioning accuracy, the Drill Star deep hole broaching machine precisely machines deep holes in aero-engine combustion chambers and key components of aircraft landing gear, ensuring high reliability of complex structural parts and helping aerospace equipment break through performance limits. Driven by technological innovation and customer-oriented, the Drill Star deep hole broaching machine provides professional and efficient machining solutions for various industries! Contact us now to unlock new possibilities in precision machining!

Automotive Industry: Efficient production of automotive parts relies on advanced equipment. The Drill Star deep hole broaching machine can quickly complete precision machining of oil holes in automotive engine blocks and spline holes in transmissions, shortening production cycles, improving component precision and consistency, and providing a solid guarantee for the stable operation of automotive powertrain and transmission systems.

Energy Equipment: Facing the stringent demands of oil and gas extraction equipment, the Drill Star deep hole broaching machine excels. It can machine deep-hole drill pipes and hydraulic support column inner holes used in oil and gas field exploration, withstanding high-intensity pressure and complex working conditions, contributing to the efficient and safe operation of energy extraction equipment.

Mold Manufacturing: Mold precision directly affects product molding quality. The Drill Star deep hole broaching machine, through its powerful broaching capabilities and high-precision control, processes mold cooling holes and ejector pin holes, optimizing mold heat dissipation and demolding performance, and improving mold production efficiency and service life.

Military Industry: Military equipment has extremely high requirements for the precision and reliability of component machining. The Drill Star deep hole broaching machine, with its stable performance, processes deep holes in gun barrel bores and precision weapon parts, ensuring high precision and high safety of military products and contributing to national defense.