Iron-based wrought high-temperature alloys are a class of metallic materials with iron (Fe) as the principal element, engineered to maintain good mechanical strength and resistance to degradation (like oxidation) at elevated temperatures, typically in the range of 540°C to 760°C (1000°F to 1400°F). The “wrought” designation indicates they are shaped by thermomechanical processes such as hot rolling, forging, or extrusion, which refine their microstructure to provide a favorable combination of strength, ductility, and fabricability.

They serve as a cost-effective and highly versatile solution for a wide array of high-temperature applications, bridging the performance gap between stainless steels and more expensive nickel or cobalt-based superalloys.

Good High-Temperature Strength & Creep Resistance: They resist deformation and slow, time-dependent strain (creep) under mechanical load at elevated temperatures, though their upper temperature limit is generally lower than that of nickel-based superalloys.

Excellent Oxidation & Corrosion Resistance: A key feature is their ability to form a protective, adherent chromia (Cr₂O₃) scale on the surface, thanks to high chromium content (typically 12-28%). Many grades also contain silicon (Si) and aluminum (Al) to form even more stable scales.

Cost-Effectiveness: Based on an iron matrix, they are significantly less expensive than nickel or cobalt-based alternatives, making them the material of choice for large-scale or cost-sensitive applications.

Good Fabricability: Their wrought nature means they can be readily formed, machined, and welded into complex components using standard industrial practices.

The high-temperature performance of these alloys is achieved through several synergistic mechanisms:

Solid Solution Strengthening: Elements like molybdenum (Mo), tungsten (W), and chromium (Cr) dissolve in the iron matrix, impeding dislocation movement and providing baseline strength.

Carbide Precipitation Strengthening: The formation of stable carbides (e.g., M₂₃C₆, MC, where M is Cr, Mo, Nb) at grain boundaries and within the grains helps to pin dislocations and grain boundaries, enhancing strength and creep resistance.

Nitride and Carbonitride Precipitation: In certain alloys, elements like niobium (Nb) and titanium (Ti) form fine nitrides or carbonitrides that provide additional precipitation strengthening.

Microstructural Stability: The alloy compositions are balanced to resist the coarsening of these strengthening phases and the formation of detrimental intermetallic compounds during long-term exposure to heat.

Iron-based wrought high-temperature alloys are workhorses across numerous industries:

Power Generation:

Turbine Blades & Discs in steam turbines and lower-temperature stages of gas turbines.

Boiler Tubing, Superheater & Reheater Tubes, and heat exchangers in fossil fuel power plants.

Automotive:

Turbocharger Housings (Turbine Housings) that must withstand exhaust gas temperatures.

Exhaust Manifolds and downpipes.

Industrial Furnaces & Heat Treatment:

Radiant Tubes, Muffles, Trays, and baskets used in carburizing, annealing, and other heat-treating processes.

Petrochemical & Refining:

Tubing for furnace coils and piping for high-temperature process streams in catalytic crackers and reformers.

The following table summarizes the key features for a quick overview:

| Feature | Description | Advantage |

| Base Element | Iron (Fe), with high Chromium (Cr) content. | Provides a cost-effective foundation with inherent oxidation resistance. |

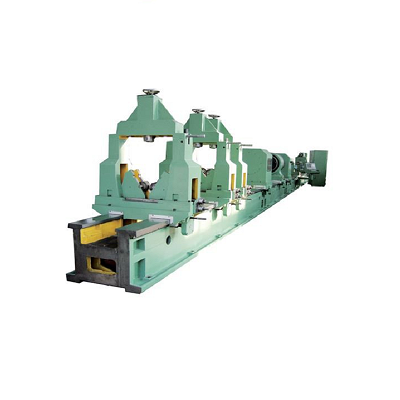

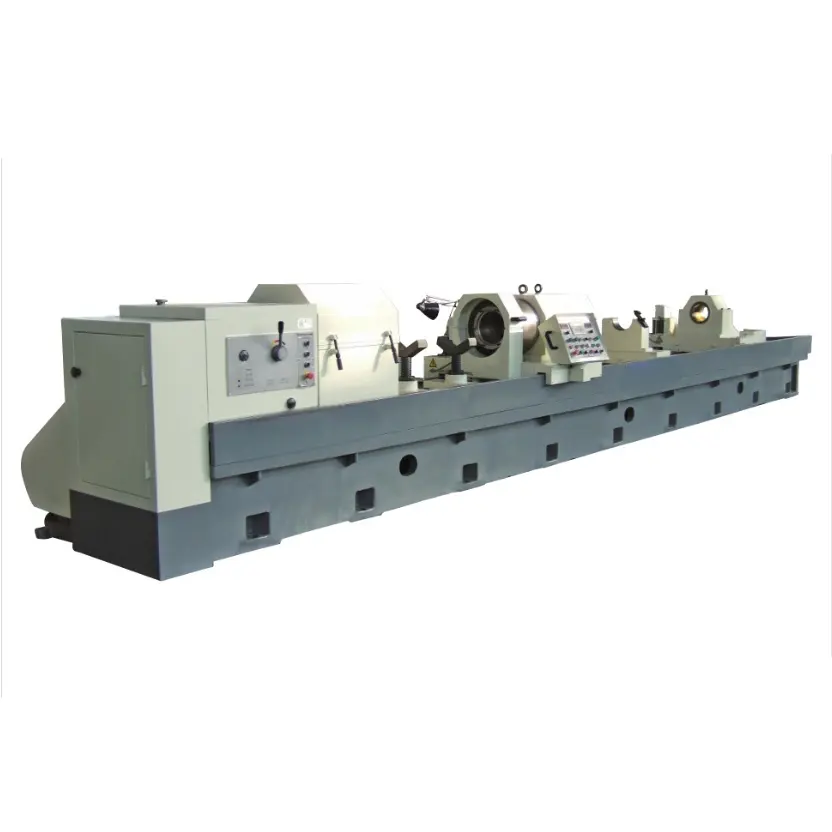

| Manufacturing Route | Thermomechanical Processing (Hot Rolling, Forging). | Results in a uniform, fine-grained structure with good ductility and toughness. |

| Key Strengtheners | Solid Solution (Mo, W); Carbides (Cr, Nb, Mo). | Provides a balanced combination of high-temperature strength and microstructural stability. |

| Temperature Range | Good performance up to ~760°C (1400°F). | Fills the critical performance gap between standard stainless steels and nickel superalloys. |

| Key Benefit | An optimal balance of performance, fabricability, and cost. | The most economical solution for a vast number of high-temperature engineering challenges. |

| Common Alloys & Types | Austenitic (e.g., 304H, 316H, 321H, 347H); Ferritic (e.g., 446); Precipitation-Hardenable (e.g., A-286, 17-4PH). | Offers a wide selection for different temperature, strength, and corrosion requirements. |

In summary, Iron-Based Wrought High-Temperature Alloys are a fundamental and versatile class of materials that enable a vast portion of modern high-temperature engineering. Their development represents a masterful optimization of cost and performance, making them indispensable for applications ranging from the family car to the power plant that supplies its electricity.