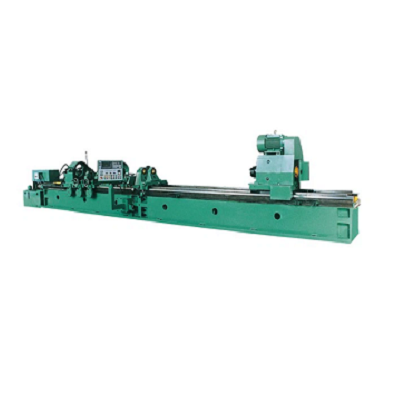

HMS25 HMS35 HMS50 Deep Hole Honing Machine is specially used for finishing the inner hole surface of various hydraulic cylinders, cylinders and other cylindrical parts. After machining, the aperture accuracy of the parts reaches above it7, and the surface roughness reaches ra0.2-0.4 μ m。 The machine tool can also carry out local honing to correct the taper and ovality of parts.

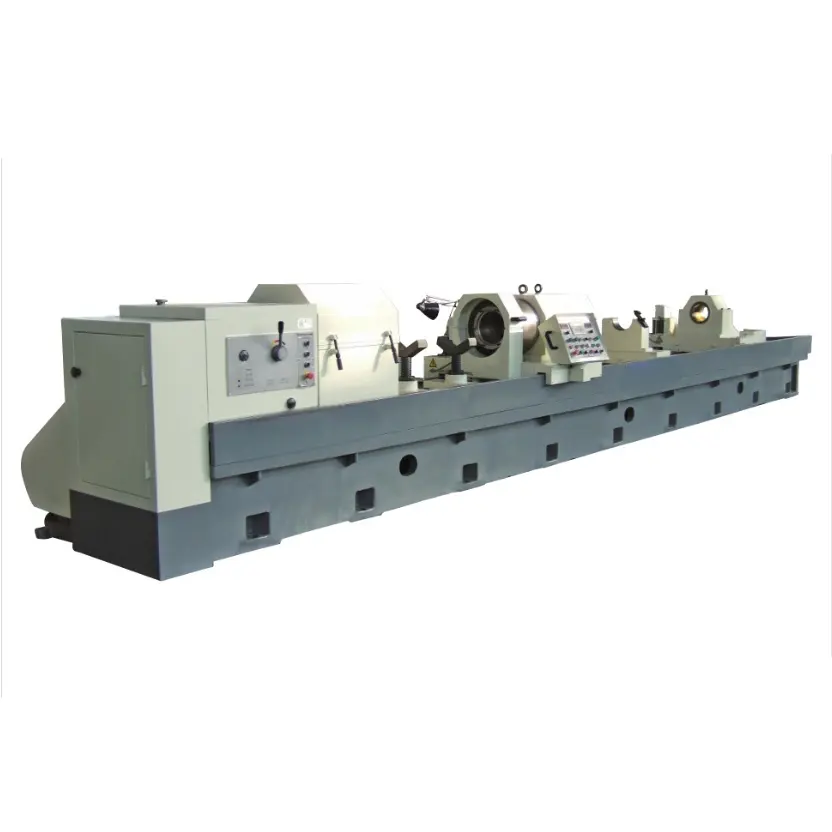

2M2150 deephole honing machine is ideal equipment for deephole machining with high accuracy and high efficiency.This machine is matde with SIEMENS or FANUC CNC system.AC servo motor,honing box adopt stepless speed,and it also mated with Germany ATLANTA high accuracy racks and gears to realize the reciprocating of honing head and it can control the honing position too.This machine is matde with linear guide way and it have service life and high accuracy.

The usage of 2M2125A 2M2135A Deep Hole Honing Machine is a special equipment used for honing cylindrical deep hole parts such as various hydraulic oil cylinders and cylinders. Hole Diameter accuracy of machined workpieces can be up to or over IT7 and surface roughness Ra0.2-0.4μm. It can also repair and maintain taper and ellipticity of machined workpieces with the help of partial honing.

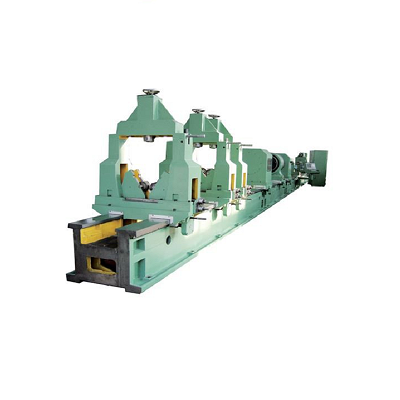

This machine tool is a specialized machine tool for machining cylindrical deep-hole parts, suitable for drilling and boring of cylindrical deep-hole workpieces. During drilling, an internal chip removal method (BTA method) is used, i.e., oil is supplied by an oil feeder, and the cutting chips are discharged from inside the drill rod to the chip hopper at the rear of the machine head through the cutting zone. During boring, oil is supplied from the tail end of the boring bar, and the chips are discharged to the chip hopper at the head of the machine head through the cutting zone.

This machine tool is a special-purpose machine tool for machining cylindrical deep-hole parts. It is suitable for boring cylindrical deep-hole workpieces. During boring, an oil feeder is used to supply oil, and the chips are discharged to the chip hopper at the head of the machine through the cutting zone. During drilling, an internal chip removal method (BTA) is used, that is, an oil feeder supplies oil, and the chips are discharged from the inside of the drill rod to the chip hopper at the rear of the machine through the cutting zone.

This machine tool is a special-purpose machine tool for machining cylindrical deep-hole parts. It is suitable for drilling and boring cylindrical deep-hole workpieces. During boring, an oil feeder is used to supply oil, and the chips are discharged to the chip hopper at the head of the machine through the cutting zone. During drilling, an internal chip removal method (BTA) is used, that is, an oil feeder supplies oil, and the chips are discharged from the inside of the drill rod to the chip hopper at the rear of the machine through the cutting zone.

The RFD6ZX1010-1000 six-axis drilling and milling compound deep hole drilling machine is mainly used for deep hole drilling and milling. Equipped with a high-precision CNC turntable (B-axis) and a sliding table rotation axis (A-axis), it can complete five-sided drilling and milling with one clamping. This expands the machine’s processing range, reduces clamping times, greatly improves processing accuracy and efficiency, and effectively saves production costs. It is mainly used for oblique hole processing in molds, mechanical parts, etc.

The RFD6ZX1010-1000 six-axis drilling and milling compound deep hole drilling machine is mainly used for deep hole drilling and milling. Equipped with a high-precision CNC turntable (B-axis) and a sliding table rotation axis (A-axis), it can complete five-sided drilling and milling with one clamping. This expands the machine’s processing range, reduces clamping times, greatly improves processing accuracy and efficiency, and effectively saves production costs. It is mainly used for oblique hole processing in molds, mechanical parts, etc.

Four Axis CNC Deep Hole Gun Drilling Machine is used for processing automobiles, motorcycles, oil pump, nozzle, engineering machinery, mining machinery, military industry and other industries, small and medium-sized deep hole axial workpiece of special equipment.

Large aperture deep hole drill i a deep hole machining machine that integrates BTA drill cutter drill,and gun dril,with a driling diameter of up to φ120mm. High efficient,high-precision,and high smoothness machining of large holes,with a smoothness of Ra0.4~0.8.

Single axis CNC Deep Hole Gun Drilling Machine is used for processing automobiles, motorcycles, oil pump, nozzle, engineering machinery, mining machinery, military industry and other industries, small and medium-sized deep hole axial workpiece of special equipment.

Machining accuracy meausre of skewness: 1mm/1000mm(workpiece is not rorate) 0.5mm/10...