Our triple-blade end mills combine precision manufacturing (5-axis grinding) and premium materials (e.g., YG10X carbide) to deliver consistent performance in industrial production.

AG Solid Carbide End Mills(Drillstar brand) are designed to perform in the most demanding environments. Whether you’re looking for an end mill for aluminum, titanium, stainless steel, or different materials, our end mills will provide you with the ultimate MRR and durability. AG Solid Carbide End Mills run longer, cut faster, and machine with greater precision. Solid Carbide End Mills are designed to perform in the most demanding environments. Whether you’re looking for an end mill for aluminum, titanium, stainless steel,etc.

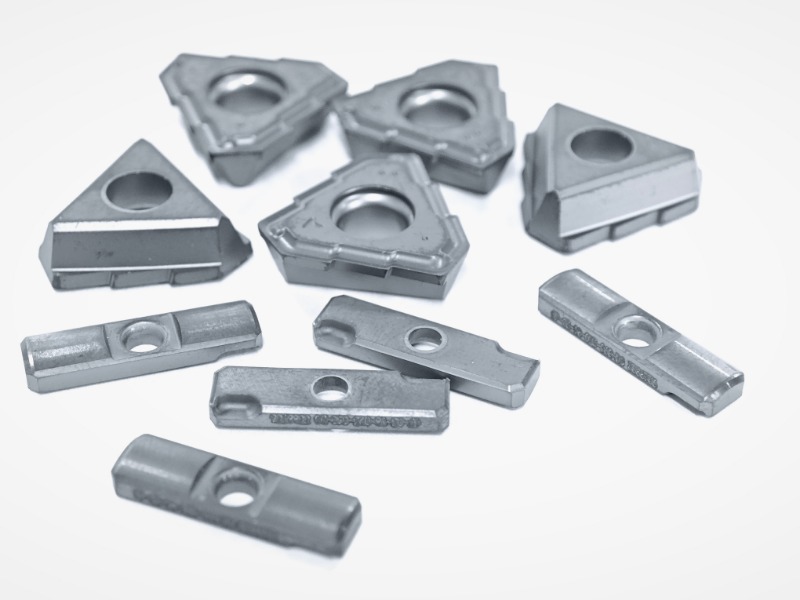

Indexable reamers are precision hole-finishing tools for metalworking, featuring replaceable carbide inserts (no regrinding needed) and modular designs. They deliver high accuracy, efficiency, and cost-effectiveness in mass production, replacing traditional solid reamers for medium-to-large batch machining. Our reamers are engineered with advanced insert clamping, internal coolant systems, and wear-resistant coatings to meet strict tolerance and surface finish requirements.

This carbide gun drill, also known as a deep hole cutting insert drill, represents an advanced and efficient solution for deep hole machining. It integrates drilling, boring and reaming into a single operation, enabling high – precision hole processing in one pass. Crafted from premium carbide materials with specialized coating and structural design, it excels in handling harsh machining conditions while maintaining excellent stability and long service life, making it a core tool for precision manufacturing across multiple industries.

The carbide gun drill feather key is a precision-engineered guide & positioning component for carbide gun drills (deep-hole drilling tools). It ensures stable cutting, accurate hole alignment, and extended tool life during high-precision deep-hole machining. Made of premium tungsten carbide (WC-Co) with advanced coating technology, it delivers exceptional wear resistance and load-bearing capacity in harsh machining environments.

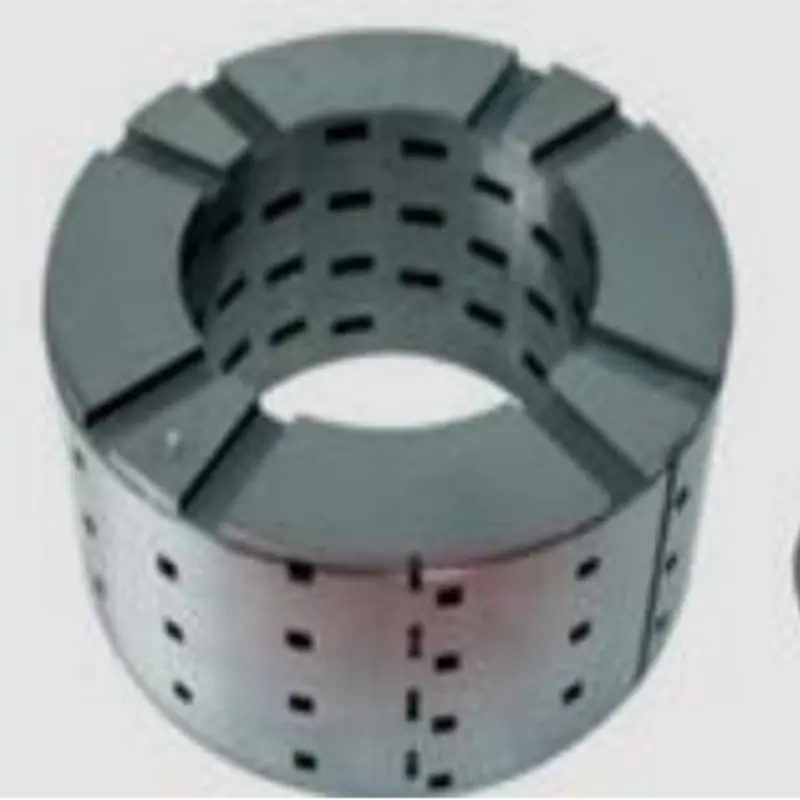

Valve internals refer to the critical components housed within a valve body that directly control the flow, direction, and pressure of a fluid (liquid or gas). While the valve body contains the pressure, it is the internals that perform the essential work of sealing, modulating, and shutting off the flow. Their performance and durability are paramount to the entire system’s reliability. These components are typically designed as replaceable parts, allowing for maintenance and repair without replacing the entire valve body.

Carbide Plum Blossom Teeth are a specialized type of tungsten carbide cutting tool characterized by their unique, multi-pointed star shape that resembles a plum blossom. These teeth are designed as highly efficient, multi-faceted cutting elements for extreme abrasive and impact conditions, primarily in the mining and construction industries.

The term “Carbide Water Tap” does not typically refer to a standard household faucet. Instead, it describes a specialized tungsten carbide valve component or a wear-resistant tap used to control the flow of water, slurry, or other abrasive fluids in industrial settings. The “carbide” designation indicates that the critical wear-prone parts of this valve are made from or protected by tungsten carbide to ensure extreme durability.

A Composite Sheet Substrate refers to a base material, typically in sheet form, that is composed of two or more distinct physical or chemical phases combined to create a new material with superior properties compared to its individual components. In advanced industrial contexts, this often involves combining a tough, ductile matrix (like a metal or polymer) with a hard, reinforcing phase (like ceramic particles or fibers) to achieve a balance of strength, toughness, and other specific functional properties. These substrates are engineered to serve as a foundational platform for further processing or as a core structural component in demanding applications.

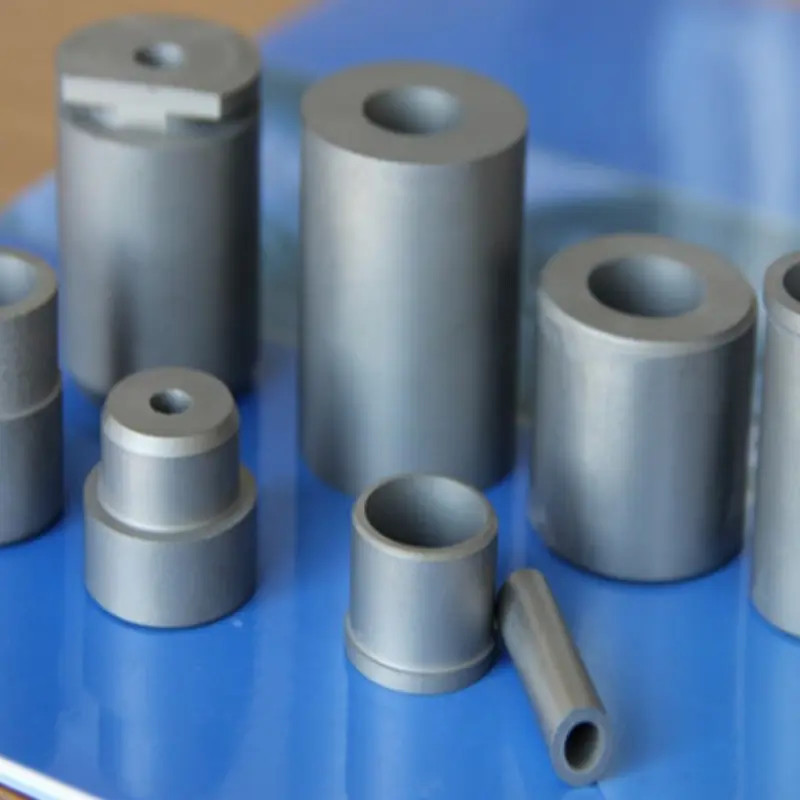

Carbide drill bits are high-performance cutting tools designed for drilling into hard, abrasive, or challenging materials. They are distinguished by their cutting edges or tips, which are made from tungsten carbide, a composite material known for its superior hardness and wear resistance compared to standard high-speed steel (HSS).

Carbide Ball Teeth, also known as carbide ball inserts, tungsten carbide ball teeth, or conical picks, are a specific type of wear part and cutting tool characterized by their hemispherical (ball-shaped) head made of tungsten carbide. They are primarily designed for robust impact, crushing, and grinding applications, rather than precise shearing or slicing. Their unique design allows them to transmit high point load forces into the material, making them ideal for breaking extremely hard and abrasive substances.

Carbide cutting teeth refer to the tooth-like or tip components made from tungsten carbide, a composite material known for its exceptional hardness, wear resistance, and durability. These teeth are typically brazed or mounted onto various tools and machinery to serve as the primary cutting, drilling, or grinding surface.