Cemented carbide ball is a spherical cemented carbide product made by high-precision forming and sintering processes. It has extremely high hardness, wear resistance, corrosion resistance and dimensional accuracy. Widely used in bearings, valves, precision instruments, abrasive media and other fields, it can be used as rolling elements, seals, grinding media, etc., with the characteristics of long service life and stable operation.

Wear-Resistant Alloys are a class of materials specifically engineered to withstand surface degradation and material loss caused by mechanical wear. This wear can result from abrasion (scraping), erosion (impact by particles), adhesion (galling and seizing), and impact. Their primary function is to extend the service life of industrial equipment, reduce downtime, and improve operational efficiency in demanding environments.

Rotary digging teeth are heavy-duty, replaceable cutting tools mounted on the rotating drums or heads of excavation machinery. They are the primary interface that engages with and breaks up soil, rock, and other materials. Their design is optimized for applications involving a continuous rotary motion combined with high impact and abrasion.

Coal Picks, also known as miner picks, conical picks, or rock picks, are essential cutting tools used in the mining and tunneling industries. They are specifically designed to fracture and excavate materials like coal, soft rock, and other minerals by being mounted on rotating drums of continuous miners, roadheaders, and shearers. Their primary function is to act as the point of attack, transferring the machine’s power into concentrated impact and shear force to break the material.

Carbide strips, also known as tungsten carbide strips or cemented carbide flat bars, are rectangular or flat-bar-shaped pieces made from tungsten carbide. They are engineered to provide superior wear resistance as protective liners or cutting edges on machinery and equipment subjected to severe abrasion.

Carbide blocks, also known as tungsten carbide blocks or carbide blanks, are semi-finished, solid blocks of tungsten carbide that serve as raw materials or pre-forms for a wide range of industrial applications. They are prized for their exceptional hardness, wear resistance, and compressive strength, providing a durable base for creating critical wear parts and tools.

Features: 1.Use high-quality tungsten carbide as raw material. 2.Adopt the world advanced preparation technology. 3.Various types can be produced, with German import automatic extrusion equipment.

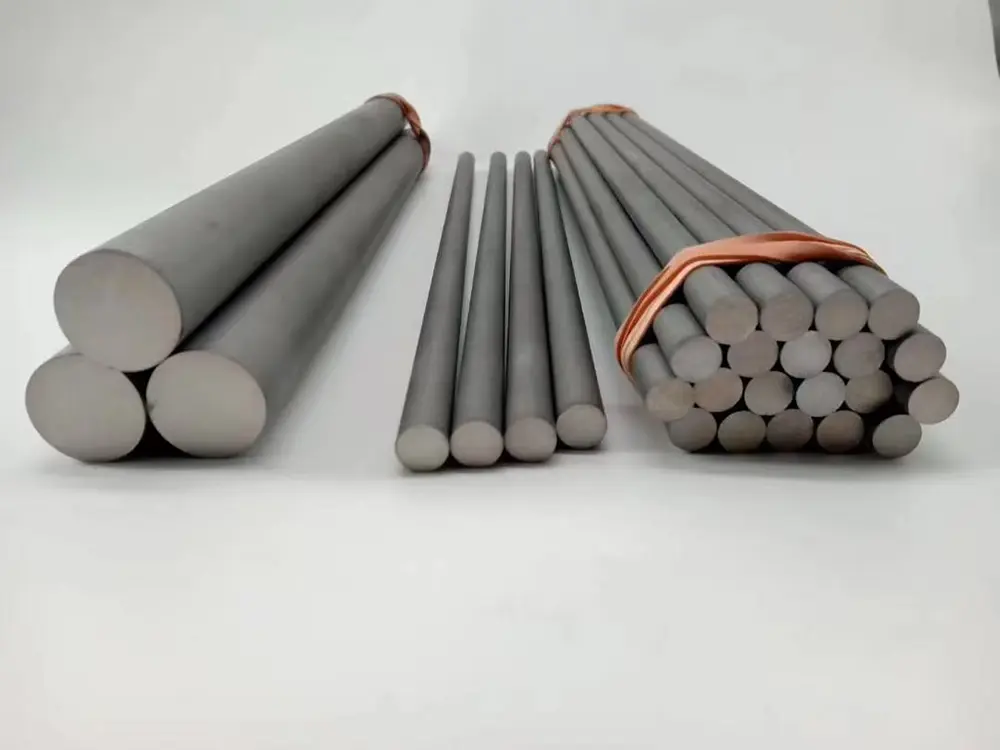

A Grade Carbide manufactures solid tungsten carbide rods in a wide range of carbide grades, lengths, and diameters. We offer both ground(h5 and h6) and as sintered (unground) solid rods, length 330mm and 310mm, and cut to length.

Threaded carbide rod with holes are mainly used for processing tungsten parts or as a tool bit of processing lathe, conductors, steel-making burdening and additives.

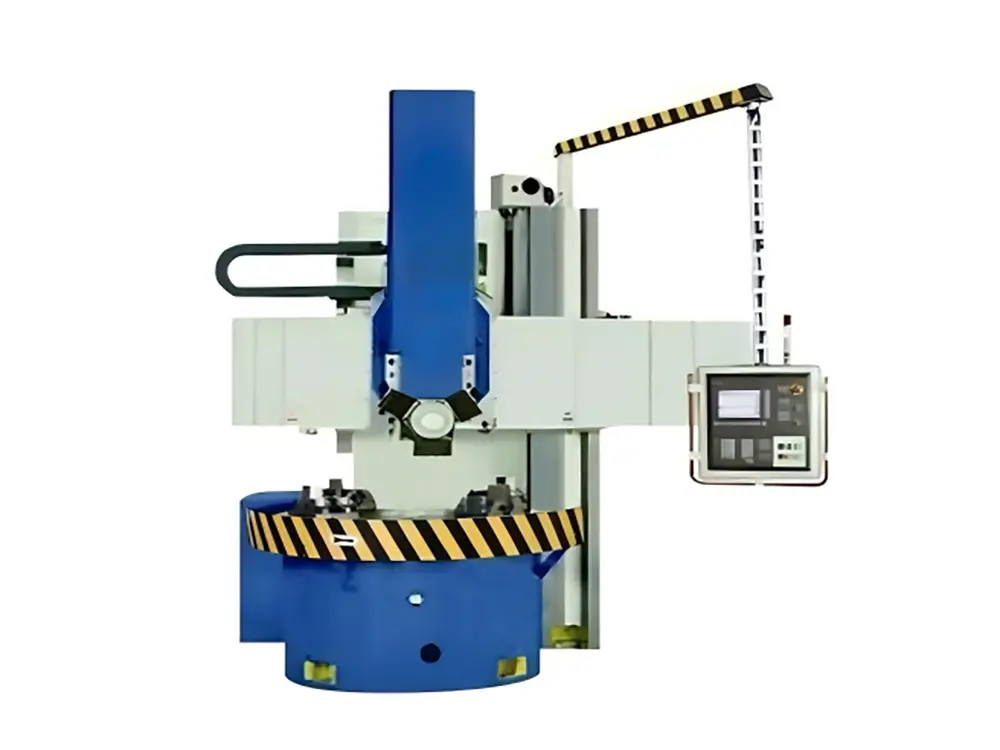

Vertical lathes (VTLs) are specialized machining equipment designed for turning large, heavy, or oversized workpieces—ideal for industries like wind power (turbine hubs), shipbuilding (hull components), mining (equipment parts), and aerospace (large structural parts).

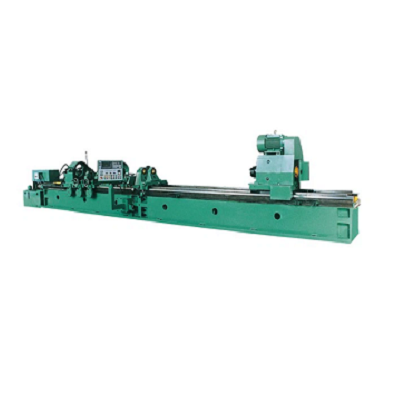

1.Equipment model: LK2120-5000 2. Rated tension: 150kN 3. Maximum stroke: 5000mm 4.Equipment use: The equipment is used to process variable lead and non-variable lead internal spirals, as well as linear grooves, and is suitable for processing products with equal wall thickness stators

HMS25 HMS35 HMS50 Deep Hole Honing Machine is specially used for finishing the inner hole surface of various hydraulic cylinders, cylinders and other cylindrical parts. After machining, the aperture accuracy of the parts reaches above it7, and the surface roughness reaches ra0.2-0.4 μ m。 The machine tool can also carry out local honing to correct the taper and ovality of parts.