Solving the problem of long service life for core components, improving efficiency and profitability! Service areas: Screw motors, rotary steerable systems, downhole drilling tools, etc.

Service Areas Screw Motors, Rotary Steerable Systems, Downhole Drilling Tools, etc. ...

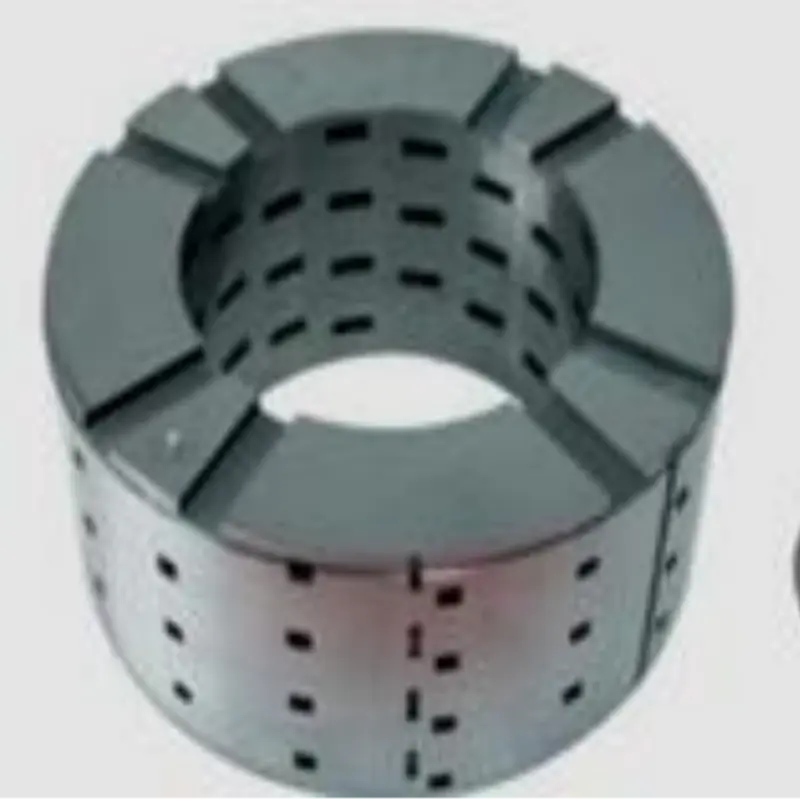

Valve internals refer to the critical components housed within a valve body that directly control the flow, direction, and pressure of a fluid (liquid or gas). While the valve body contains the pressure, it is the internals that perform the essential work of sealing, modulating, and shutting off the flow. Their performance and durability are paramount to the entire system’s reliability. These components are typically designed as replaceable parts, allowing for maintenance and repair without replacing the entire valve body.

Carbide Plum Blossom Teeth are a specialized type of tungsten carbide cutting tool characterized by their unique, multi-pointed star shape that resembles a plum blossom. These teeth are designed as highly efficient, multi-faceted cutting elements for extreme abrasive and impact conditions, primarily in the mining and construction industries.

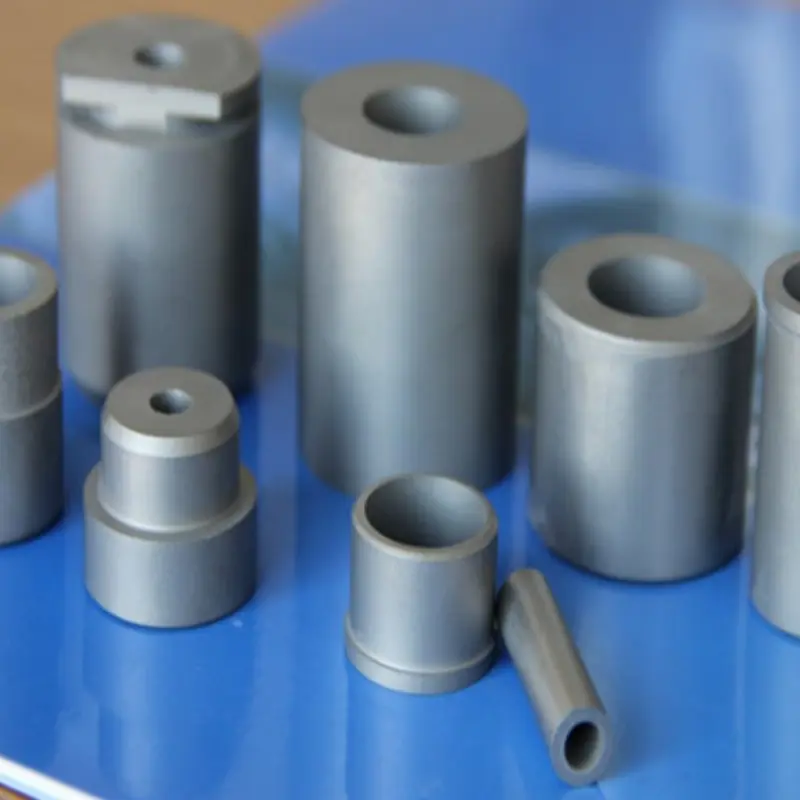

The term “Carbide Water Tap” does not typically refer to a standard household faucet. Instead, it describes a specialized tungsten carbide valve component or a wear-resistant tap used to control the flow of water, slurry, or other abrasive fluids in industrial settings. The “carbide” designation indicates that the critical wear-prone parts of this valve are made from or protected by tungsten carbide to ensure extreme durability.

A Composite Sheet Substrate refers to a base material, typically in sheet form, that is composed of two or more distinct physical or chemical phases combined to create a new material with superior properties compared to its individual components. In advanced industrial contexts, this often involves combining a tough, ductile matrix (like a metal or polymer) with a hard, reinforcing phase (like ceramic particles or fibers) to achieve a balance of strength, toughness, and other specific functional properties. These substrates are engineered to serve as a foundational platform for further processing or as a core structural component in demanding applications.