Nickel-based wrought superalloys are a class of high-performance materials designed for exceptional mechanical strength, creep resistance, and structural stability at elevated temperatures, typically above 540°C (1000°F). The term “wrought” signifies that these alloys are shaped into their final form through thermomechanical processes such as forging, rolling, or extrusion, which results in a fine, directional grain structure that provides superior tensile and fatigue properties compared to their cast counterparts. They are the backbone of high-temperature rotating components in aerospace and power generation, where failure is not an option.

Nickel-based corrosion-resistant alloys are a class of advanced metallic materials engineered primarily to withstand extreme corrosive environments. Their foundation is a nickel (Ni) matrix, which is inherently resistant to many corrosives, alloyed with other key elements—primarily chromium (Cr), molybdenum (Mo), and sometimes copper (Cu) and nitrogen (N)—to create a versatile and powerful family of materials for the most aggressive chemical and industrial applications. They are the go-to solution when stainless steels are no longer sufficient.

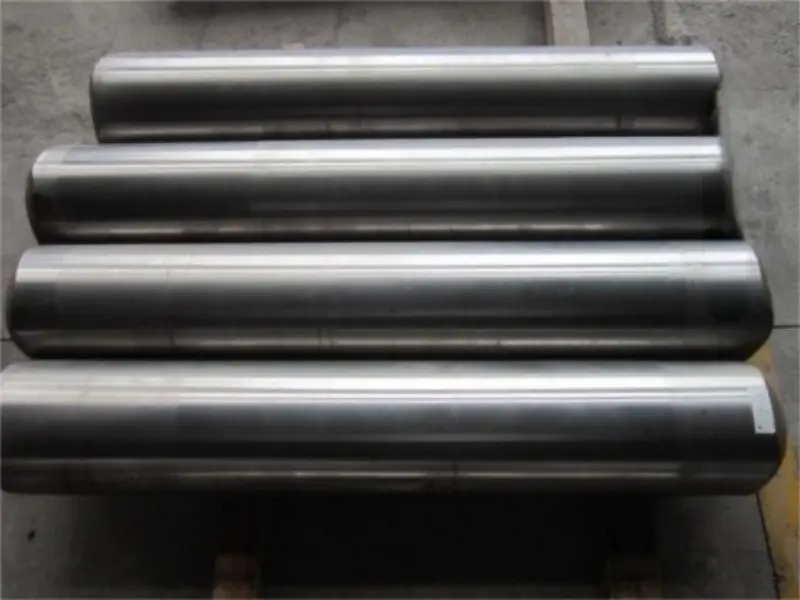

Iron-based wrought high-temperature alloys are a class of metallic materials with iron (Fe) as the principal element, engineered to maintain good mechanical strength and resistance to degradation (like oxidation) at elevated temperatures, typically in the range of 540°C to 760°C (1000°F to 1400°F). The “wrought” designation indicates they are shaped by thermomechanical processes such as hot rolling, forging, or extrusion, which refine their microstructure to provide a favorable combination of strength, ductility, and fabricability. They serve as a cost-effective and highly versatile solution for a wide array of high-temperature applications, bridging the performance gap between stainless steels and more expensive nickel or cobalt-based superalloys.

Cobalt-based superalloys are a class of high-performance metallic materials designed to maintain exceptional mechanical strength, surface stability, and corrosion resistance at extremely high temperatures, often exceeding those where nickel-based superalloys begin to weaken. They are a cornerstone material for critical components in the most demanding environments, particularly in aerospace, industrial gas turbines, and medical implants. Their superior performance stems from a strengthened cobalt-chromium matrix and a high volume of hard, refractory carbide particles.