Iron-based wrought high-temperature alloys are a class of metallic materials with iron (Fe) as the principal element, engineered to maintain good mechanical strength and resistance to degradation (like oxidation) at elevated temperatures, typically in the range of 540°C to 760°C (1000°F to 1400°F). The “wrought” designation indicates they are shaped by thermomechanical processes such as hot rolling, forging, or extrusion, which refine their microstructure to provide a favorable combination of strength, ductility, and fabricability. They serve as a cost-effective and highly versatile solution for a wide array of high-temperature applications, bridging the performance gap between stainless steels and more expensive nickel or cobalt-based superalloys.

Cobalt-based superalloys are a class of high-performance metallic materials designed to maintain exceptional mechanical strength, surface stability, and corrosion resistance at extremely high temperatures, often exceeding those where nickel-based superalloys begin to weaken. They are a cornerstone material for critical components in the most demanding environments, particularly in aerospace, industrial gas turbines, and medical implants. Their superior performance stems from a strengthened cobalt-chromium matrix and a high volume of hard, refractory carbide particles.

Solving the problem of long service life for core components, improving efficiency and profitability! Service areas: Screw motors, rotary steerable systems, downhole drilling tools, etc.

Service Areas Screw Motors, Rotary Steerable Systems, Downhole Drilling Tools, etc. ...

Comma face grooving cutters (also known as comma grooving cutters or face comma cutters) are spec...

Core Definition and Structure Grooving inserts are preformed replaceable cutting unit...

Rhombic CNC inserts are among the most widely used types of indexable inserts in CNC turning and boring processes. They are named for their rhombic shape (a quadrilateral with parallel opposite sides and fixed included angles between adjacent sides), and are primarily suitable for operations such as external turning, internal boring, and face turning.

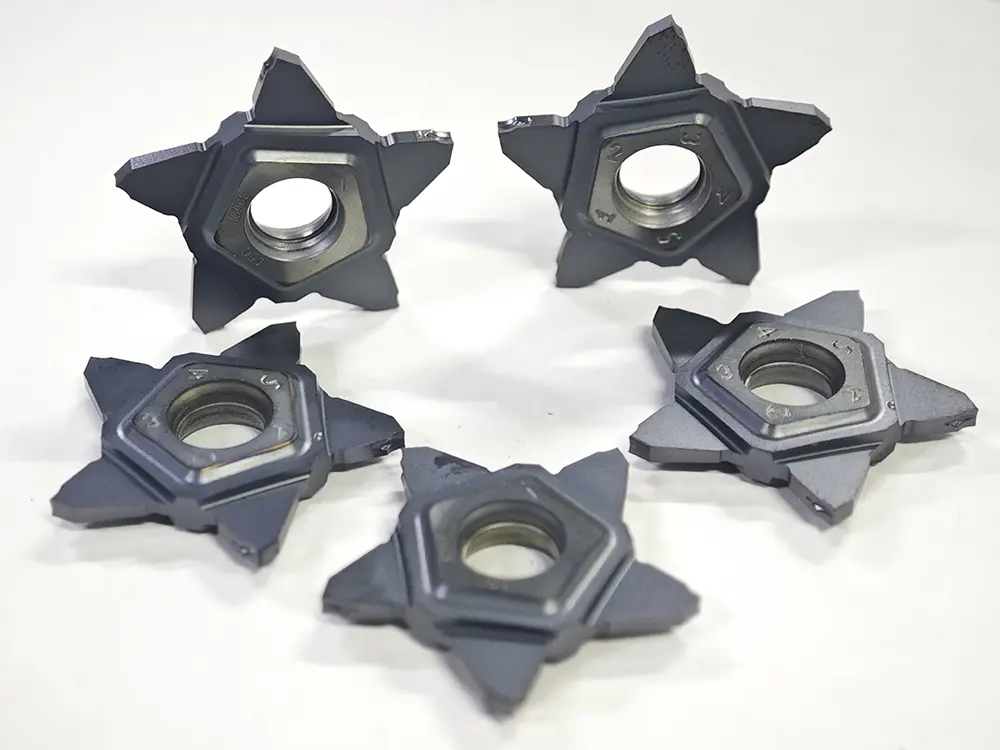

Star-shaped Grooving Cutters (also referred to as Penta Grooving Tools) are cost-effective indexable tools for CNC grooving and parting operations. They are named for their pentagram-shaped insert structure with 5 cutting edges, and are primarily suitable for machining shallow grooves, wide grooves, parting cuts, and shoulder grooves—especially ideal for small part and batch production scenarios.

Square CNC turning inserts are one of the commonly used cutting tools in CNC turning processes.

V-CUT knives (also known as V-shaped cutting knives or V-groove knives) are specialized tools for PCB (Printed Circuit Board) processing, metal sheet grooving, and V-groove machining of materials such as acrylic and plastic. Below is a detailed description from the perspectives of core characteristics, classification, parameters, and applications:

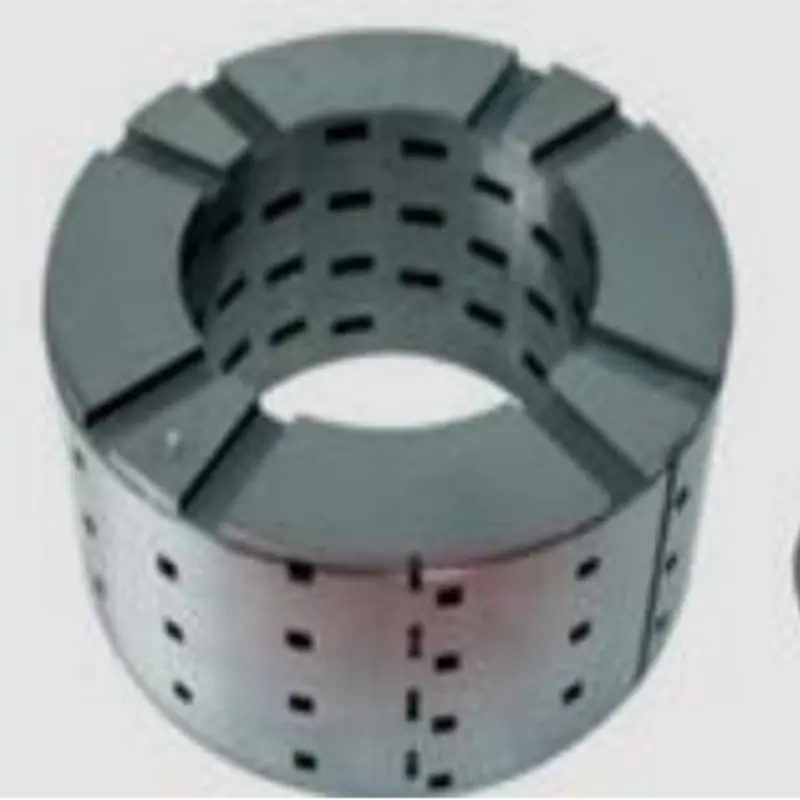

Valve internals refer to the critical components housed within a valve body that directly control the flow, direction, and pressure of a fluid (liquid or gas). While the valve body contains the pressure, it is the internals that perform the essential work of sealing, modulating, and shutting off the flow. Their performance and durability are paramount to the entire system’s reliability. These components are typically designed as replaceable parts, allowing for maintenance and repair without replacing the entire valve body.

Carbide Plum Blossom Teeth are a specialized type of tungsten carbide cutting tool characterized by their unique, multi-pointed star shape that resembles a plum blossom. These teeth are designed as highly efficient, multi-faceted cutting elements for extreme abrasive and impact conditions, primarily in the mining and construction industries.