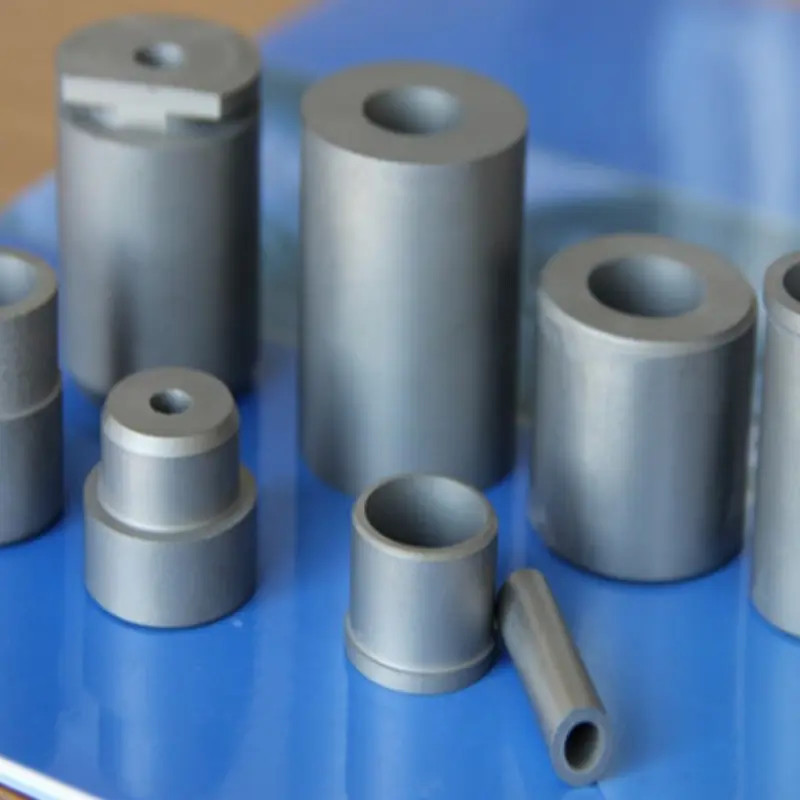

The term “Carbide Water Tap” does not typically refer to a standard household faucet. Instead, it describes a specialized tungsten carbide valve component or a wear-resistant tap used to control the flow of water, slurry, or other abrasive fluids in industrial settings. The “carbide” designation indicates that the critical wear-prone parts of this valve are made from or protected by tungsten carbide to ensure extreme durability.

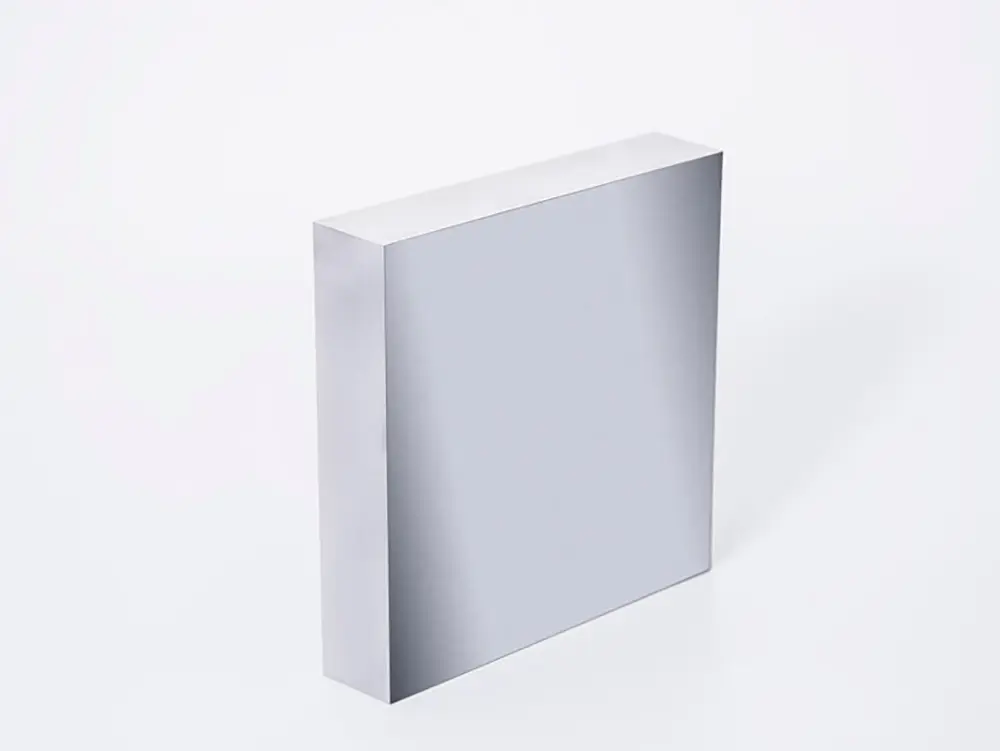

A Composite Sheet Substrate refers to a base material, typically in sheet form, that is composed of two or more distinct physical or chemical phases combined to create a new material with superior properties compared to its individual components. In advanced industrial contexts, this often involves combining a tough, ductile matrix (like a metal or polymer) with a hard, reinforcing phase (like ceramic particles or fibers) to achieve a balance of strength, toughness, and other specific functional properties. These substrates are engineered to serve as a foundational platform for further processing or as a core structural component in demanding applications.

Carbide drill bits are high-performance cutting tools designed for drilling into hard, abrasive, or challenging materials. They are distinguished by their cutting edges or tips, which are made from tungsten carbide, a composite material known for its superior hardness and wear resistance compared to standard high-speed steel (HSS).

Carbide Ball Teeth, also known as carbide ball inserts, tungsten carbide ball teeth, or conical picks, are a specific type of wear part and cutting tool characterized by their hemispherical (ball-shaped) head made of tungsten carbide. They are primarily designed for robust impact, crushing, and grinding applications, rather than precise shearing or slicing. Their unique design allows them to transmit high point load forces into the material, making them ideal for breaking extremely hard and abrasive substances.

Carbide cutting teeth refer to the tooth-like or tip components made from tungsten carbide, a composite material known for its exceptional hardness, wear resistance, and durability. These teeth are typically brazed or mounted onto various tools and machinery to serve as the primary cutting, drilling, or grinding surface.

Cemented carbide ball is a spherical cemented carbide product made by high-precision forming and sintering processes. It has extremely high hardness, wear resistance, corrosion resistance and dimensional accuracy. Widely used in bearings, valves, precision instruments, abrasive media and other fields, it can be used as rolling elements, seals, grinding media, etc., with the characteristics of long service life and stable operation.

Wear-Resistant Alloys are a class of materials specifically engineered to withstand surface degradation and material loss caused by mechanical wear. This wear can result from abrasion (scraping), erosion (impact by particles), adhesion (galling and seizing), and impact. Their primary function is to extend the service life of industrial equipment, reduce downtime, and improve operational efficiency in demanding environments.

Rotary digging teeth are heavy-duty, replaceable cutting tools mounted on the rotating drums or heads of excavation machinery. They are the primary interface that engages with and breaks up soil, rock, and other materials. Their design is optimized for applications involving a continuous rotary motion combined with high impact and abrasion.

Coal Picks, also known as miner picks, conical picks, or rock picks, are essential cutting tools used in the mining and tunneling industries. They are specifically designed to fracture and excavate materials like coal, soft rock, and other minerals by being mounted on rotating drums of continuous miners, roadheaders, and shearers. Their primary function is to act as the point of attack, transferring the machine’s power into concentrated impact and shear force to break the material.

Carbide strips, also known as tungsten carbide strips or cemented carbide flat bars, are rectangular or flat-bar-shaped pieces made from tungsten carbide. They are engineered to provide superior wear resistance as protective liners or cutting edges on machinery and equipment subjected to severe abrasion.

Carbide blocks, also known as tungsten carbide blocks or carbide blanks, are semi-finished, solid blocks of tungsten carbide that serve as raw materials or pre-forms for a wide range of industrial applications. They are prized for their exceptional hardness, wear resistance, and compressive strength, providing a durable base for creating critical wear parts and tools.

Features: 1.Use high-quality tungsten carbide as raw material. 2.Adopt the world advanced preparation technology. 3.Various types can be produced, with German import automatic extrusion equipment.