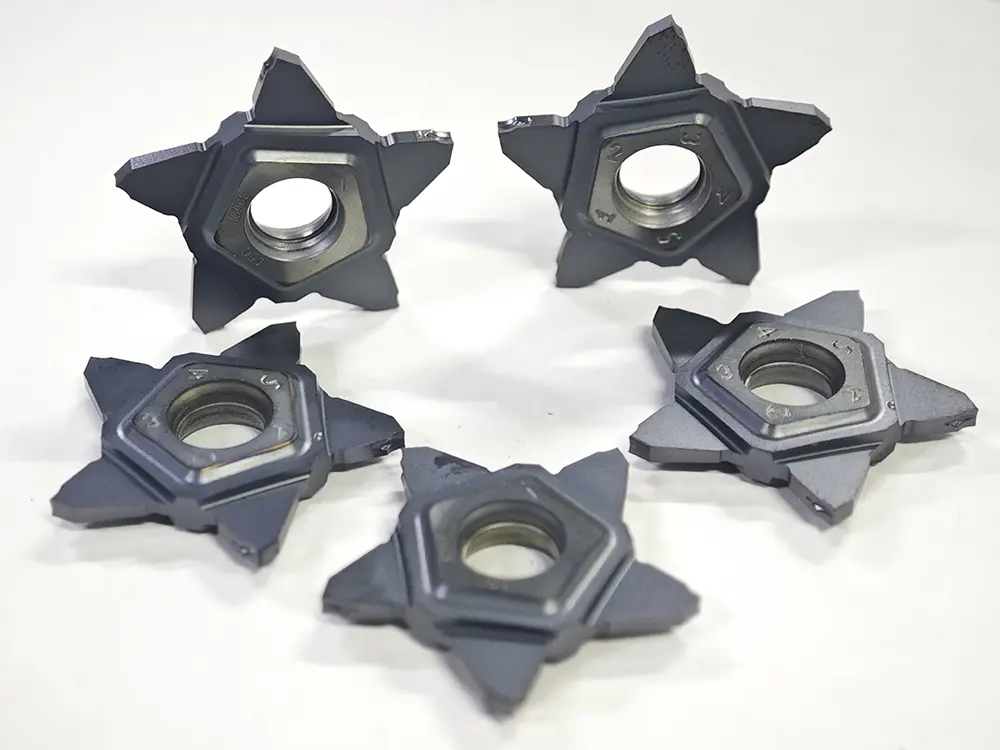

Rotary digging teeth are heavy-duty, replaceable cutting tools mounted on the rotating drums or heads of excavation machinery. They are the primary interface that engages with and breaks up soil, rock, and other materials. Their design is optimized for applications involving a continuous rotary motion combined with high impact and abrasion.

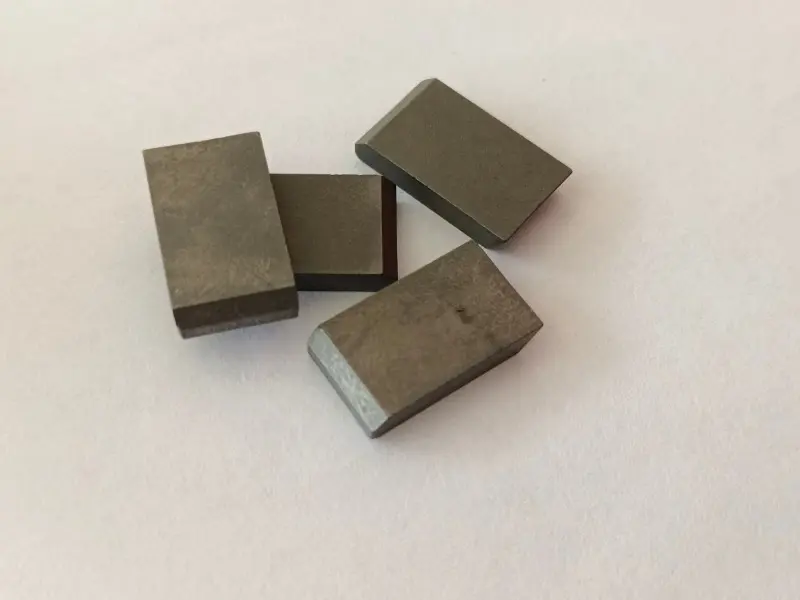

Robust Tungsten Carbide Tip: The core of the tooth features a tungsten carbide insert or tip, chosen for its superior hardness and wear resistance to withstand extreme abrasion.

High-Strength Steel Body: The body is forged from tough, impact-resistant alloy steel to absorb the massive shock loads encountered during digging and crushing. The shank is precision-engineered to fit securely into a holder or adapter.

Optimized Geometry for Rotation: These teeth have a pronounced conical, pointed, or chisel shape. This geometry is designed to efficiently penetrate and fracture material as the drum rotates, prying loose chunks rather than just grinding.

Secure Retention System: They are held in place by a robust mechanical system, typically a spring lock pin or a retainer ring. This system keeps the tooth firmly seated while allowing for relatively quick replacement when worn or broken.

The operational principle is based on transferring the machine's hydraulic power and rotational force into focused impact and shear stress on the material.

As the drum rotates, the teeth sequentially strike and penetrate the working face.

The combination of the machine's forward thrust and the rotary motion creates a prying and fracturing action.

For many designs, the asymmetric forces cause the tooth to rotate slightly in its holder with each impact. This self-rotation promotes even wear around the carbide tip, extending service life and maintaining a sharp cutting profile—a key feature similar to other rotary tools like conical picks.

Rotary digging teeth are critical components on a wide range of earth-moving and mining equipment:

Trenching & Excavation: Mounted on trencher wheels and excavator-mounted milling heads for digging utility trenches in soil and rock.

Surface Mining: Used on continuous surface miners for precise layer-by-layer mining of coal and other minerals.

Rock Wheel Excavators: Installed on the rotating heads of "rock wheels" or "rock cutters" for hard rock excavation in tunneling, quarrying, and site development.

Land Reclamation & Dredging: Employed on cutter heads of dredgers for cutting and mixing underwater materials.

The following table summarizes the key features for a quick overview:

| Feature | Description | Advantage |

| Primary Function | To cut, fracture, and break up ground material via rotary action. | Enables efficient mechanical excavation. |

| Material | Tungsten carbide tip brazed onto a high-strength steel body. | Combines extreme wear resistance with high impact toughness. |

| Core Mechanism | Impact and shear force from a rotating drum; often includes self-rotation. | Promotes even wear, self-sharpening, and long service life. |

| Key Benefit | High Excavation Efficiency & Reduced Downtime. | Maintains cutting performance in abrasive conditions, reducing replacement frequency. |

| Equipment | Trenchers, continuous surface miners, rock wheels, dredger cutters. | The essential cutting tool for rotary-style excavation machinery. |

In summary, Rotary Digging Teeth are fundamental, consumable tools that enable modern mechanical excavation. Their robust and intelligent design allows heavy machinery to efficiently and economically dig through some of the toughest materials on earth, from compacted soil to solid rock.