The RFD6ZX1010-1000 six-axis drilling and milling compound deep hole drilling machine is mainly used for deep hole drilling and milling. Equipped with a high-precision CNC turntable (B-axis) and a sliding table rotation axis (A-axis), it can complete five-sided drilling and milling with one clamping. This expands the machine’s processing range, reduces clamping times, greatly improves processing accuracy and efficiency, and effectively saves production costs. It is mainly used for oblique hole processing in molds, mechanical parts, etc.

The RFD6ZX1010-1000 six-axis drilling and milling compound deep hole drilling machine is mainly used for deep hole drilling and milling. Equipped with a high-precision CNC turntable (B-axis) and a sliding table rotation axis (A-axis), it can complete five-sided drilling and milling with one clamping. This expands the machine’s processing range, reduces clamping times, greatly improves processing accuracy and efficiency, and effectively saves production costs. It is mainly used for oblique hole processing in molds, mechanical parts, etc.

This machine integrates advanced technologies in modern industry:

The adoption of the above advanced technologies ensures that the machine’s performance, precision, processing range, operation, and work efficiency have reached the advanced level of similar machines.

| Machine Model | RFD6ZX1010-1000 | RFD6ZX1010-1000 | ||

| Item | Unit | |||

| 1. Hole diameter processing range | mm | Φ4~Φ38 | ||

| 2. Maximum drilling depth (W axis) | mm | 1000 | ||

| 3. Worktable left-right travel (X axis) | mm | 1300 | ||

| 4. Spindle up-down travel (Y axis) | mm | 1000 (900 above worktable, 100 below worktable) | ||

| 5. Worktable front-back travel (Z axis) | mm | 700 | ||

| 6. Square ram rotation (A axis) | degrees | Spindle head up 20°, down 45° | ||

| 7. Worktable rotation (B axis) | degrees | 360 | ||

| 8. Gun drill spindle maximum speed | rpm | 6000 | ||

| 9. Spindle feed speed | mm/min | 0~3000 | ||

| 10. Gun drill spindle motor power | kW | 15/18.5 | ||

| 11. Rapid traverse (X/Y/Z/W/) | m/min | 10/7.5/10/10 | ||

| 12. Worktable left-right movement motor (X axis) | kW | 5.9 | ||

| 13. Spindle up-down movement motor (Y axis) | kW | 5.9 | ||

| 14. Spindle front-back movement motor (W axis) | kW | 3.9 | ||

| 15. Worktable front-back movement motor (Z axis) | kW | 5.9 | ||

| 16. Slide rotary motor (A axis) | kW | 5.9 | ||

| 17. Turntable motor (B axis) | kW | 5.9 | ||

| 18. Total machine motor power | kW | 45 | ||

| 19. Rotary worktable load capacity | kg | 3000 | ||

| 20. Rotary worktable minimum division degree | degrees | 0.001 | ||

| 21. Rotary worktable area (length × width) | mm | 800X800 | ||

| 22. Coolant flow range | L/min | 0~80 | ||

| 23. Coolant pressure range | MPa | 0-10 | ||

| 24. Machine floor area (length X width) | mm | 6350X4030 | ||

| 25. Maximum machine height | mm | Sheet metal height 3250, maximum height 4500 | ||

| 26. Machine weight | ton | 14 | ||

One set of RFD6ZX1010-1000 six-axis drilling and milling compound deep hole drilling machine, configured as follows:

| Serial Number | Configuration | Remarks |

| 1 | Syntec 220MA CNC system | |

| 2 | Handwheel control box | |

| 3 | Full machine protective cover | |

| 4 | Centralized lubrication station | |

| 5 | Drilling cooling system | |

| 6 | Drilling air pressure system | |

| 7 | Spiral chip conveyor (3 units) | |

| 8 | Macro program | |

| 9 | Gun drill elastic chuck (Φ25) | |

| 10 | Three-color warning light | |

| 11 | Adjustment tools | |

| 12 | Work light | |

| 13 | Foundation pads, bolts | |

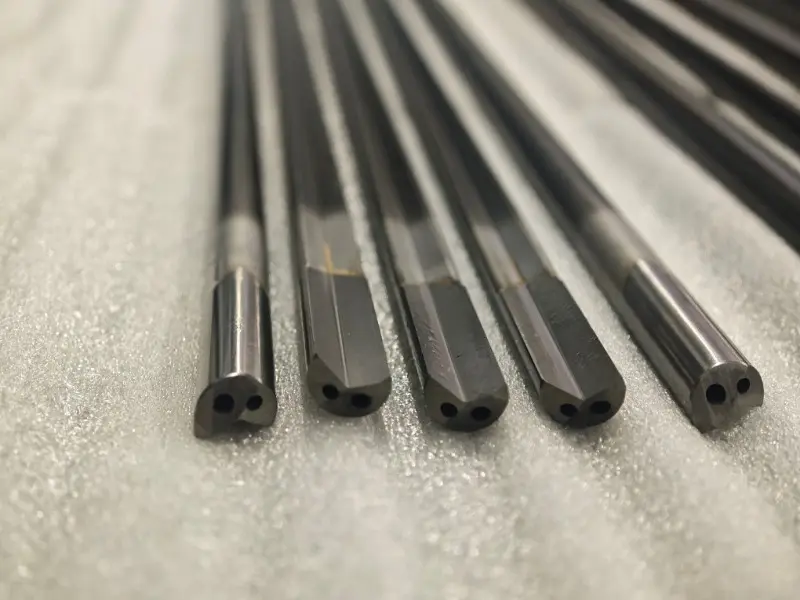

| 14 | Φ10.02 deep hole drill bit and guide sleeve (1 each), BT40 tool holder (1) | |

| 15 | Electrical cabinet air conditioner | |

| 16 | Oil temperature controller | |

| 17 | Hydraulic counterweight | |

| 18 | Guide seat (1), guide brackets (2) | |

| 19 | A axis gear drive | |

| 20 | Guide rails: X: RGW45 (2), Y: RGW55 (2) + RGW45 (1), Z: RGW45 (4), W: RGW45 (2) | |

| 21 | Ball screws: X/Y/Z/W: R5010 |

| Serial Number | Name |

| 1 | None |

| 2 | None |

| 3 | None |

1.Machine operation manual

2.CNC system operation manual

3.CNC system maintenance manual

4.Qualification certificate

5.Packing list

| Component Name | Supplier |

| 1. CNC system and servo motor | Syntec |

| 2. Main electrical components | Schneider |

| 3. Linear guides | Taiwan HIWIN |

| 4. Ball screws | Taiwan TBI/HIWIN |

| 5. Hydraulic components | Yuci Yuken |

| 6. Pneumatic components | AIRTAC |

| 7. Lubrication components | Deyang/Huangjinjia |

| 8. Filters | Qinghui Hydraulics |

| 9. Spindle | Taiwan Danquan/Jianchun |

| 10. CNC rotary table | Yantai Universal |

The buyer shall complete the equipment foundation work and have installation conditions two weeks before the seller’s equipment leaves the factory according to the seller’s equipment foundation diagram. The seller shall provide all materials required for installation (including layout plan and positions of power points for electricity, oil, gas, etc.) within 30 days after the contract takes effect to the buyer for preparing equipment foundation and energy configuration in advance to ensure the seller’s on-site construction on schedule.

During on-site installation and commissioning, the seller shall appoint an on-site person in charge to supervise on-site and handle all issues related to the site. During on-site installation and commissioning, the seller shall report the construction progress and quality as required by the buyer, and the rectification items proposed by the buyer shall be resolved through friendly negotiation between both parties.

After the seller completes the machine installation, the buyer shall send technical personnel for acceptance. The acceptance items shall be in accordance with <Dongguan Ruifeng Precision Machinery Co., Ltd. Machine Tool Accuracy Inspection Items>>.

After the machine is accepted, the seller’s technical personnel shall train the buyer’s operators until they can fully operate the machine independently.

Customer Installation and Commissioning Preparation Form

Prepare a 45KW power supply and a 16mm2 power cable between the machine and the power supply, with the length determined by the actual distance between the machine and the power supply.

Prepare an air source with a pressure of 5kg/cm2.

Prepare 800 liters of special cooling cutting oil for deep hole drilling (requiring extreme pressure additives).

Prepare 4 liters of 46# guide rail lubricating oil.

Before the machine is transported to the work site, please clear the passage that affects transportation.

Ambient temperature: -5℃ ~45℃

Power supply: Three-phase 380V±10%, 50Hz

| Item Status | Dark brown transparent liquid | Kinematic viscosity 40cst | 13-18 |

| Flash point (open) ℃ | Not lower than 100 | Safety test | (-10℃) qualified |

| Acid value | Mg koh/g not more than 2 | Sintering load PB.N | Not less than 6080 |

| Pour point ℃ | Not higher than -8 |

| Serial Number | Inspection Item | Tolerance |

| 1 | Straightness of the worktable moving along the X axis in the X-Y plane | Local arbitrary 300mm measuring length: 0.02 |

| 2 | Inclination of the worktable when moving along the X axis | 0.02/300 over full stroke |

| 3 | Perpendicularity of Y axis movement to the worktable surfacea: In X-Y planeb: In Y-Z plane | 300mm lengtha: 0.02b: 0.02 |

| 4 | Perpendicularity between W axis movement of the spindle box and X axis movement | 0.02 over any 300mm measuring length |

| 5 | 1. Parallelism between spindle box movement along W axis and worktable surface2. Parallelism between worktable movement along Z axis and worktable | 1. 0.03 over 300mm length2. 0.02 over full stroke |

| 6 | a. Indexing accuracy of the rotary table | a. ±0.006° |

| b. Bidirectional repeat positioning accuracy | b. ±0.003° | |

| 6 | a. Indexing accuracy of A axis rotation | a: ±0.006° |

| b. Repeat positioning accuracy of A axis rotation | b: ±0.003° | |

| 7 | Bidirectional positioning accuracy of X, Y, Z axis movements | X axis 0.02Y axis 0.02Z axis 0.02 |

| 8 | Bidirectional repeat positioning accuracy of X, Y, Z axis movements | X axis 0.015Y axis 0.015Z axis 0.015 |

Working accuracy inspection

| Material | Hole depth mm | Tool | Hole diameter tolerance | Feed rate mm/min | Hole deflection (vertical/horizontal) | |

| Oblique hole | Straight hole | |||||

| 45 | 300 | Φ10.02 drill bit | IT8~IT10 | 50 | 0.2/300 | 0.15/300 |

Notes: 1. Deflection of the drill hole center from the reference plane. 2. Standard test piece length 300mm, material 45, normalized state. 3 Effective measuring length for guaranteed hole diameter quality: hole diameter * 100. 4. Roundness of drilled hole: 0.008~0.015. 5. Roughness of drilled hole: 3.2 to 0.4. 6. Hole diameter accuracy grade: IT8~IT10.

The quality guarantee period for domestically sold products is calculated from the date of equipment installation and acceptance, with a warranty period of one year.

During the warranty period, except for damage caused by human factors and force majeure, if the equipment itself has quality problems, the company’s maintenance services and material costs are fully covered.

During the warranty period, if the domestically sold equipment malfunctions, both parties can communicate through telephone, fax or email to solve the problem. If the buyer cannot solve the problem by themselves, the seller shall send personnel to the factory for maintenance within 24 hours.

Our company provides lifelong technical support for the equipment. After the warranty period, if our service is needed, we only charge cost fees.