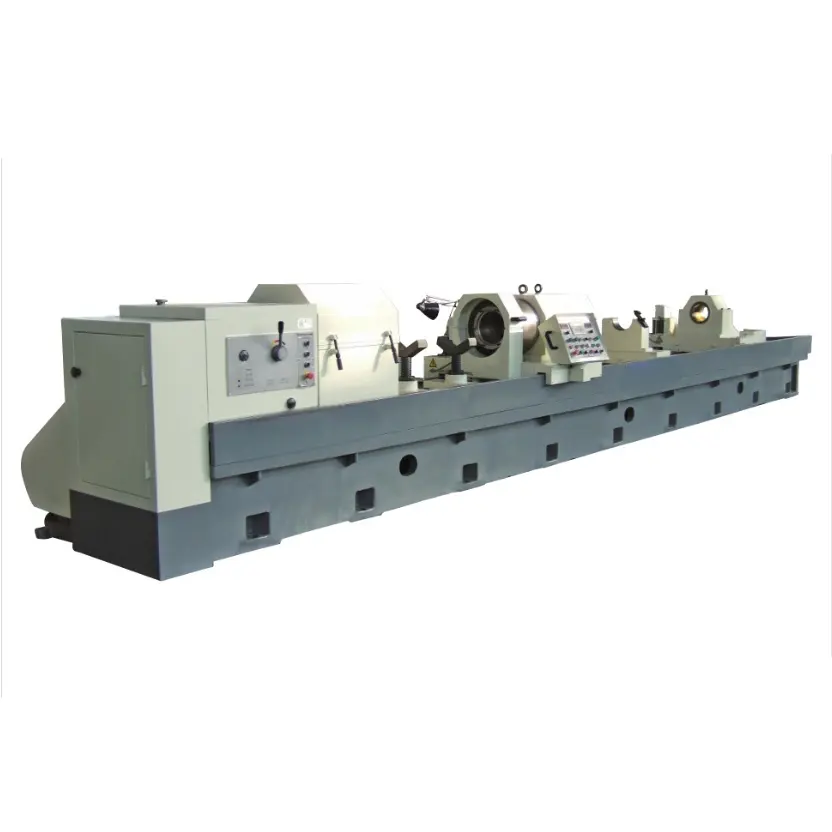

This machine tool is a specialized machine tool for machining cylindrical deep-hole parts, suitable for drilling and boring of cylindrical deep-hole workpieces. During drilling, an internal chip removal method (BTA method) is used, i.e., oil is supplied by an oil feeder, and the cutting chips are discharged from inside the drill rod to the chip hopper at the rear of the machine head through the cutting zone. During boring, oil is supplied from the tail end of the boring bar, and the chips are discharged to the chip hopper at the head of the machine head through the cutting zone.

Machine Tool Application: This machine tool is a special-purpose machine tool for machining cylindrical deep-hole parts, suitable for drilling and boring of cylindrical deep-hole workpieces. During drilling, an internal chip removal method (BTA method) is used, i.e., oil is supplied by an oil feeder, and the cutting chips are discharged from inside the drill rod to the chip hopper at the rear of the machine head through the cutting zone. During boring, oil is supplied from the tail end of the boring bar, and the chips are discharged to the chip hopper at the headstock through the cutting zone.

The machine tool bed guideway is rectangular and hardened for high wear resistance; the feed screw is installed in the middle of the bed guideway. The oil feeder uses a servo motor to clamp the workpiece, with adjustable pressure, ensuring safety and reliability. The oil feeder spindle has high concentricity with the machine tool spindle, resulting in good rotational accuracy; the guide sleeve is easy to replace. This machine tool is a deep hole drilling and boring machine that is easy to operate and control, and has high processing efficiency.

| Project Name | parameter | |

| T2150 | ||

| Drilling diameter range

(mm) |

40-100 | |

| Boring hole diameter range

(mm) |

50-500 | |

| Maximum depth of boring

(mm) |

2000-12000 | |

| Workpiece clamping diameter range

(mm) |

300~650 | |

| Headstock spindle bore

(mm) |

130 | |

| Main motor | N=30kW

N = 960 r/min |

|

| spindle front taper hole | Metric

140# |

|

| Spindle speed range

(rpm) series |

3.15~315

Level 21 |

|

| Drill rod box rotation speed range

(rpm) series |

60~1000

Level 12 |

|

| Boring bar box motor | N=30kW

N=1460r/min |

|

| Feed rate range

(mm/min) |

5-1000

Variable |

|

| Rapid movement speed of the tray

(mm/min) |

2000 | |

| feed motor | Yaskawa AC servo motor

N=7.5kW |

|

| Cooling pump motor | Yaskawa AC servo motor

N=7.5kW |

|

| Cooling system rated pressure

(MPa) |

2.5 | |

| Cooling system flow

(l/min) |

200、400

600、800 |

|

| Main machining accuracy of machine tools | IT7~IT9 | |

| Maximum load capacity of machine tool

(t) |

10 | |