Solving the problem of long service life for core components, improving efficiency and profitability!

Service areas: Screw motors, rotary steerable systems, downhole drilling tools, etc.

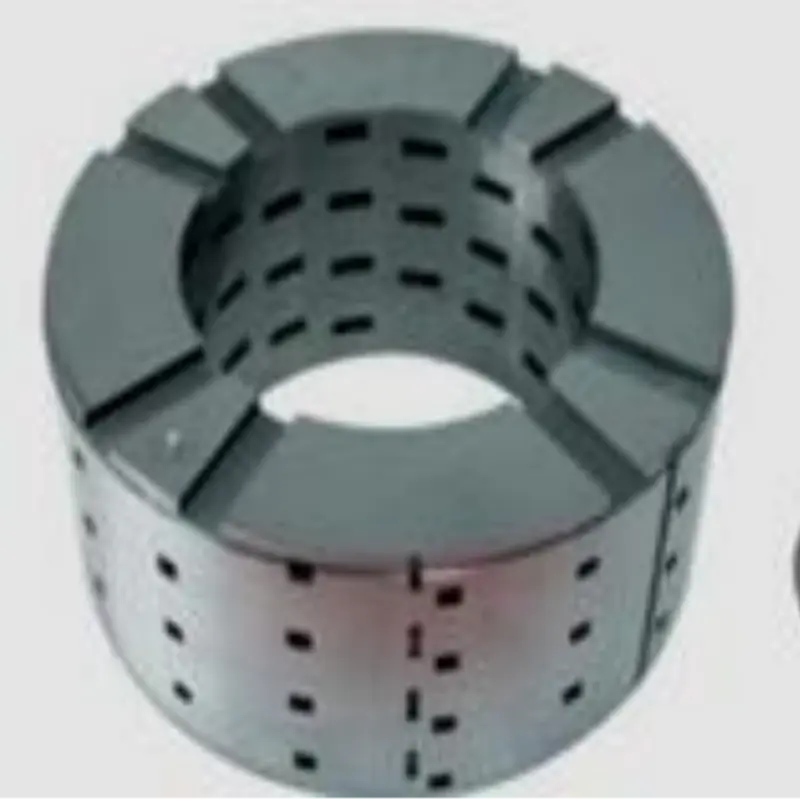

| Product Name | Specifications and model number | Alloy materials | Base material | |

| 42CrMo | ||||

| Rotary guide bearing | 675 | Zy11-G/SD168 | 4月17日 | |

| 4140 | ||||

| Rotary guide bearing | 950 | Zy11-G/SD168 | P550 | |

| 4340 | ||||

| Screw motor bearing | 120 | Zy11-G/SD158 | 4145 | |

| Screw motor bearing | 165 | Zy11-G/SD158 | ||

| Screw motor bearing | 185 | Zy11-G/SD158 | ||

| Screw motor bearing | 244 | Zy11-G/SD158 |

◆ Carbide inserts are fixed in a nickel-based binder phase containing cast WC particles, improving the product's corrosion resistance;

◆ Perfectly combines the wear resistance of carbide with the toughness of steel;

◆ The edges of the flow channels are specially reinforced to enhance the bonding strength and toughness, preventing brittle chipping and spalling of the hardened layer;

◆ Low-temperature preparation process preserves the excellent mechanical properties of heat-treated steel;

◆ Non-stick threads;

◆ High bonding strength between the hard surface layer and the steel substrate;

◆ Specially designed carbide blocks possess high wear resistance and fracture toughness;

◆ Excellent impact and erosion resistance;

◆ High load capacity;

◆ Longer service life than traditional sintering processes and coated products;

◆ Reusable;

◆ Lower cost per drilling operation;

◆ Maintains consistently excellent performance in any harsh working conditions;

◆ Lower replacement frequency and reduced inventory requirements;

◆ Provides your drilling tools with superior reliability and high competitiveness.

Operating conditions:

Location: Texas, USA

Product: Lower radial bearing

Rotational speed: 400-450 r/min

Slurry concentration: 5-6%

Problems:

* Large amounts of cemented carbide blocks are peeling off.

* Numerous cracks on the cemented carbide surface.

* Threads are seizing, making disassembly difficult.

* Base material is deformed, rendering the product unusable. * Microcracks on the cemented carbide surface.

* No cemented carbide block peeling.

* Threads are not seizing, disassembly is smooth.

* Still reusable.

Solution:

◆ The cemented carbide inserts are fixed in a nickel-based binder phase containing cast WC particles.

◆ This perfectly combines the wear resistance of cemented carbide with the toughness of steel.