Valve internals refer to the critical components housed within a valve body that directly control the flow, direction, and pressure of a fluid (liquid or gas). While the valve body contains the pressure, it is the internals that perform the essential work of sealing, modulating, and shutting off the flow. Their performance and durability are paramount to the entire system’s reliability.

These components are typically designed as replaceable parts, allowing for maintenance and repair without replacing the entire valve body.

The specific components vary by valve type (e.g., globe, gate, ball, check), but key internals often include:

Trim: This is a collective term for the set of components that come into direct contact with the flowing fluid and control it. ce that forms a seal with the closure member (e.g., plug, ball, gate). It is critical for achieving tight shut-off.

The "trim" typically includes:

Seat: The stationary surfaClosure Member (Disc, Plug, Ball, Gate): The movable component that moves against or away from the seat to stop or allow flow.

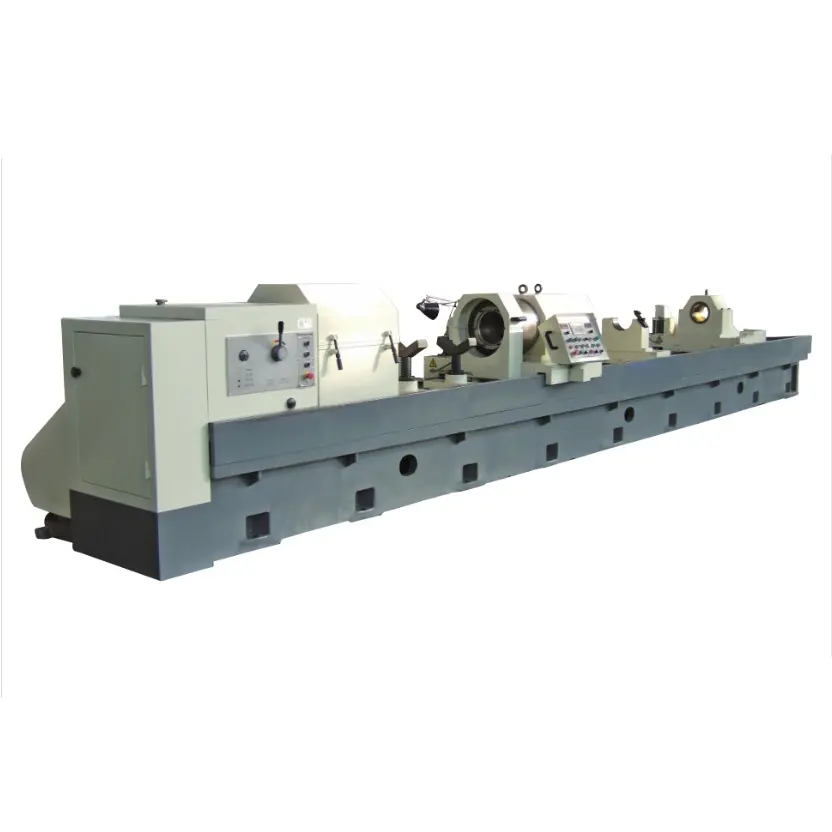

Stem: The shaft that connects the actuator (manual handwheel or automated system) to the closure member, transmitting the force to open or close the valve.

Cage: A part that surrounds the closure member in certain control valves. It guides the plug, provides stability, and its ports or holes help control flow characteristics and reduce cavitation and noise.

Seals & Gaskets: These include O-rings, gland packings, and gaskets that prevent leakage along the stem (stem sealing) and between the valve body and bonnet.

Valve internals operate in extremely demanding environments, facing:

Erosion: Caused by high-velocity or particle-laden fluids.

Corrosion: From chemically aggressive media.

Cavitation: The formation and collapse of vapor bubbles, causing surface pitting.

High-Pressure/Temperature: Leading to galling (adhesive wear) and deformation.

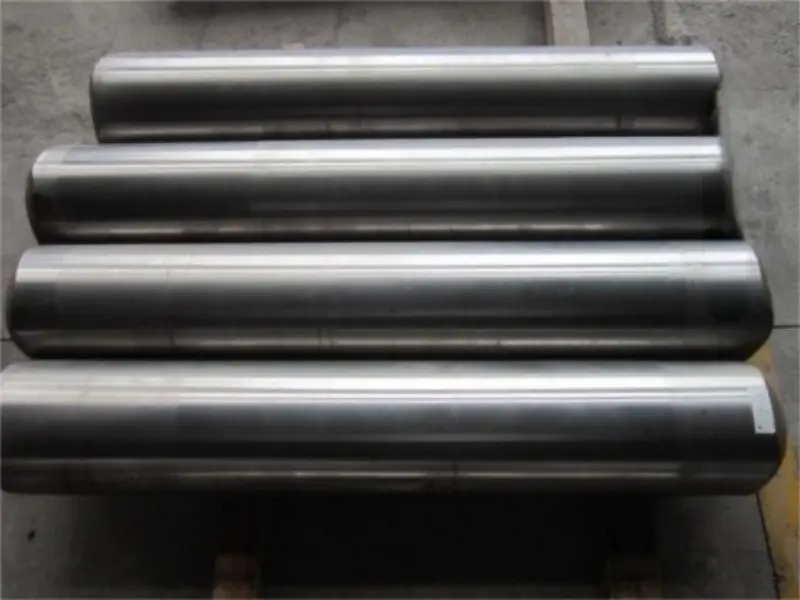

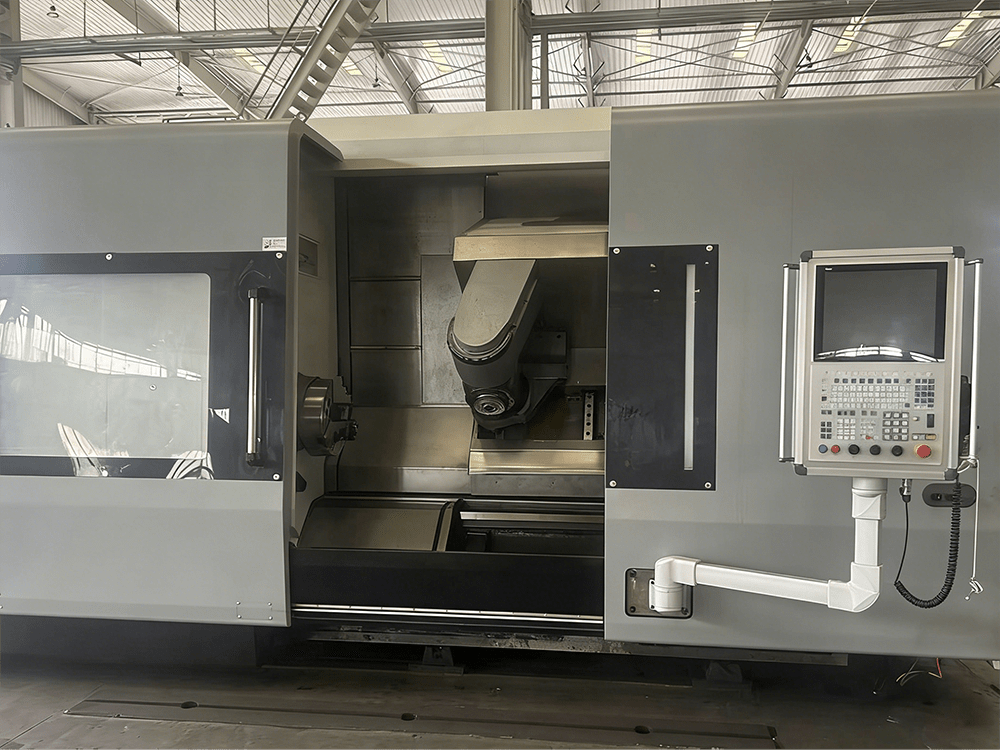

To combat these issues, valve internals are often made from or protected by advanced materials, with tungsten carbide being a top choice for the most severe services.

The following table summarizes common valve internals, their challenges, and typical material solutions:

| Component | Function | Common Wear Mechanisms | Typical Material Solutions |

| Seat | Provides a sealing surface for shut-off. | Erosion, Cavitation, Galling, Corrosion. | Tungsten Carbide, Stellite (Cobalt-Chrome), 316SS, Alloy 6, Ceramics. |

| Closure Member (Plug/Disc) | Moves to open/close the flow path. | Erosion, Cavitation, Galling, Corrosion. | Tungsten Carbide, Stellite, 316SS, Hardened Steels. |

| Stem | Transmits motion from actuator to closure member. | Abrasion, Fatigue, Corrosion. | 17-4PH Stainless Steel, Nitrided Steels, Corrosion-Resistant Alloys. |

| Cage | Guides the plug and controls flow characteristics. | Severe Erosion, Cavitation, Noise/Vibration. | Tungsten Carbide, Stellite, 316SS, Duplex Stainless Steels. |

| Seals & Gaskets | Prevents external and internal leakage. | Extrusion, Chemical Degradation, Heat Aging. | PTFE (Teflon), Grafoil, Elastomers (Viton, EPDM). |

In critical applications found in the oil & gas, power generation, and chemical processing industries, tungsten carbide is specified for trim components because of its:

Exceptional Erosion Resistance: To withstand sand and other hard particles in the fluid stream.

Outstanding Cavitation Resistance: Its hardness prevents material loss from imploding vapor bubbles.

High Compressive Strength: To resist deformation under high pressure.

Good Galling Resistance: When paired with a compatible material, it reduces the risk of seizing.

In summary, Valve Internals are the heart of the valve. Their selection, particularly the choice of wear-resistant materials like tungsten carbide for trim parts, is a critical engineering decision that directly determines the valve's performance, service life, and overall system safety in challenging operational conditions.