Vertical lathes (VTLs) are specialized machining equipment designed for turning large, heavy, or oversized workpieces—ideal for industries like wind power (turbine hubs), shipbuilding (hull components), mining (equipment parts), and aerospace (large structural parts).

Vertical lathes (VTLs) are specialized machining equipment designed for turning large, heavy, or oversized workpieces—ideal for industries like wind power (turbine hubs), shipbuilding (hull components), mining (equipment parts), and aerospace (large structural parts).

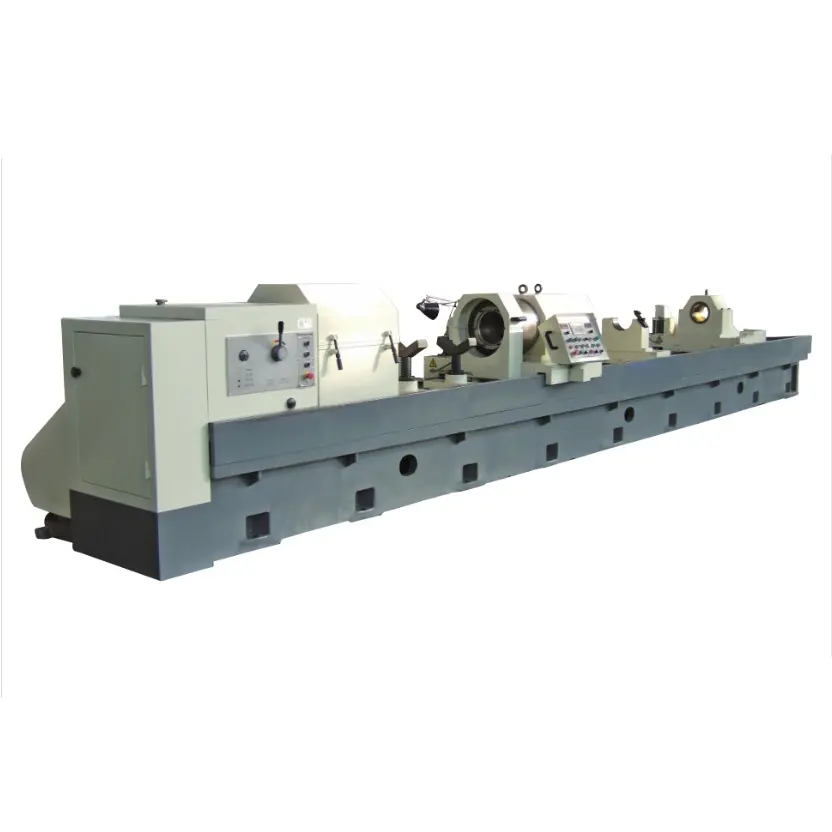

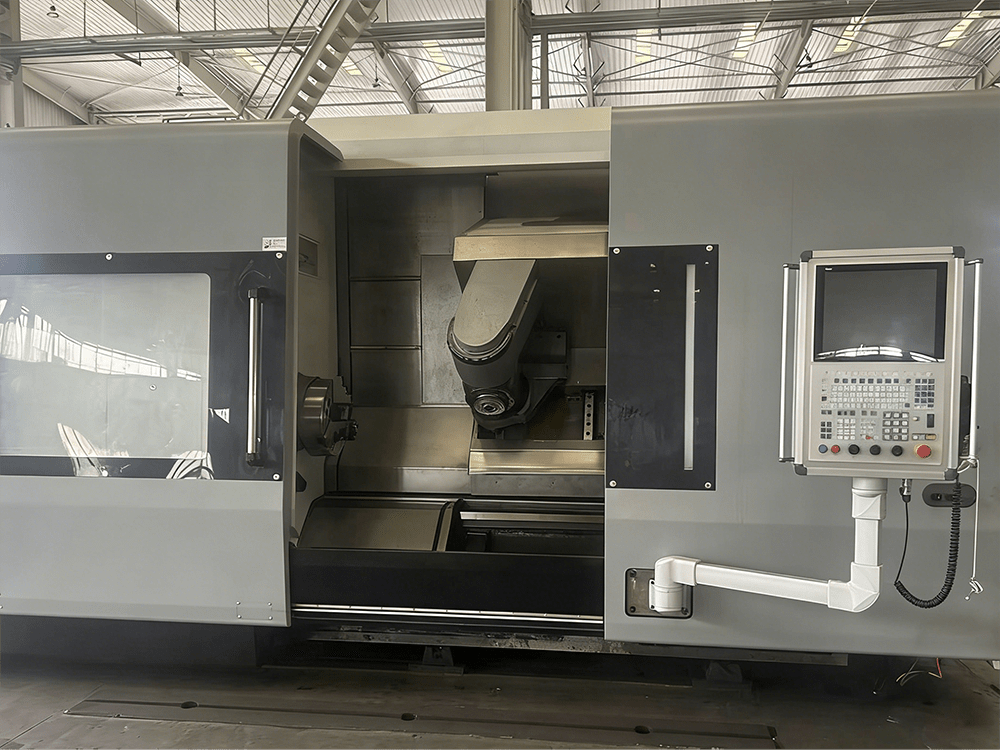

Available in multiple types (e.g., CNC double-column VTLs, single-column heavy-duty VTLs, and automatic vertical turning machines), they cater to diverse production needs: double-column models handle ultra-large workpieces with high stability, while CNC variants enable precise, automated operation for complex parts like flanges or gears.

Key attributes include high load-bearing capacity (supporting tons of workpiece weight), large swing diameter (accommodating wide components), high machining accuracy (ensuring tight tolerances for industrial parts), and efficient cutting performance—making them a core asset for heavy manufacturing and precision component production.

| Workbench rpm range | r/min | 5-250 | 5-200 | 5-180 |

| tool post rapid feed speed | mm/min | 4000 | 4000 | 4000 |

| tool post feed speed range | mm/min | 0.5~1000 | 0.5~1000 | 0.5-1000 |

| main motor power | kw | AC 22 | AC 30 | AC 30 |

| machine tool weight | t | 13/14 | 16/17/18 | 18/19/20 |