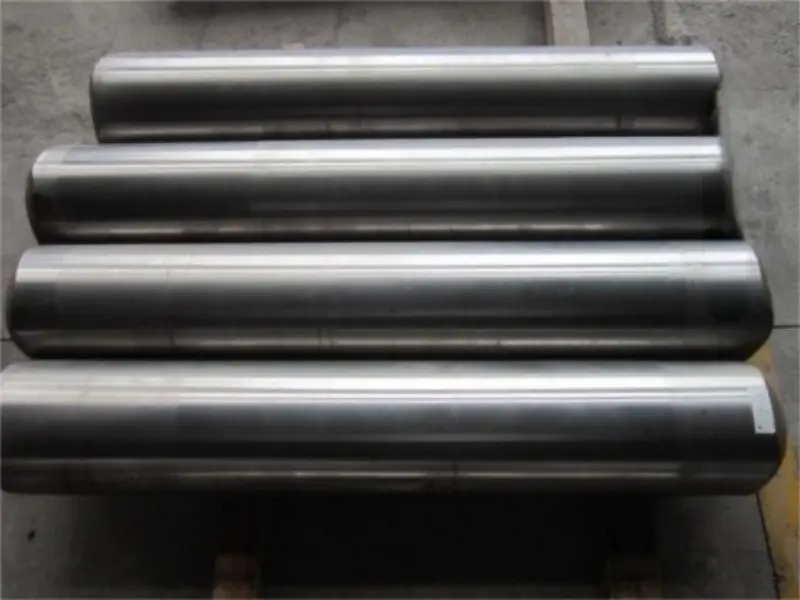

Carbide blocks, also known as tungsten carbide blocks or carbide blanks, are semi-finished, solid blocks of tungsten carbide that serve as raw materials or pre-forms for a wide range of industrial applications. They are prized for their exceptional hardness, wear resistance, and compressive strength, providing a durable base for creating critical wear parts and tools.

Exceptional Hardness & Wear Resistance: As a bulk form of tungsten carbide, these blocks offer superior resistance to abrasion, making them ideal for applications involving constant friction and material flow.

High Compressive Strength: They can withstand immense pressure without deforming, a critical property for use in heavy machinery and tooling.

Good Structural Integrity: Manufactured through powder metallurgy, they provide a uniform and dense structure suitable for further machining.

Versatility in Post-Processing: While extremely hard, they can be ground, wire-cut (by EDM), or brazed into final components with specialized equipment.

Carbide blocks are produced using powder metallurgy techniques:

Pressing: Tungsten carbide powder is mixed with a cobalt (or nickel) binder and pressed into a block form using a mold.

Sintering: The "green" block is then heated in a vacuum furnace at a temperature below its melting point. This process causes the powder particles to bond together, resulting in a dense, solid mass.

Carbide blocks are rarely used as-is. They are most commonly machined into specific components or used as wear-resistant liners.

Wear Parts & Liners: Used in chutes, hoppers, pumps, and cyclones to line surfaces exposed to highly abrasive materials (e.g., sand, ore, coal).

Tooling & Dies: Machined into forming dies, stamping dies, and drawing dies for metalworking and wire production.

Anvils & Rolls: Used in high-pressure processes like diamond synthesis (HPHT anvils) or as rolls in rolling mills.

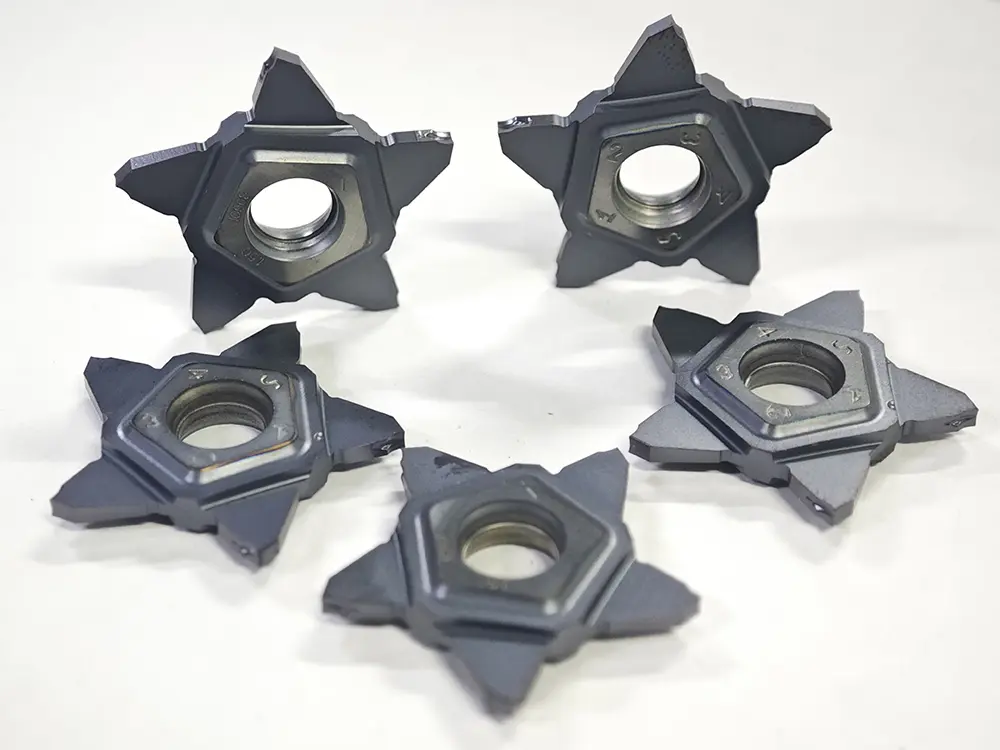

Pre-forms for Cutting Tools: Sintered blocks are cut and ground into indexable inserts, milling cutter blanks, and other custom tool geometries.

The following table summarizes the key features for a quick overview:

| Feature | Description | Advantage |

| Form | Semi-finished solid block or blank. | Serves as a versatile raw material for fabricating custom wear parts. |

| Material | Tungsten carbide with a cobalt/nickel binder. | Provides bulk hardness, wear resistance, and strength. |

| Manufacturing | Powder pressing and sintering. | Creates a dense, uniform, and high-performance material structure. |

| Core Value | Durability and Customization. | Can be machined into complex, long-lasting components for extreme conditions. |

| Key Benefit | Extended Service Life in Abrasive Environments. | Protects machinery and reduces downtime by providing a superior wear surface. |

| Common Applications | Abrasion-resistant liners, tooling dies, anvils, pre-forms for tools. | The foundational material for creating heavy-duty industrial components. |

In summary, Carbide Blocks are the fundamental building blocks of durability in many industries. They offer engineers and designers a robust, high-performance material that can be customized into virtually any shape to solve severe wear problems, ultimately enhancing the longevity and reliability of industrial equipment.