This carbide gun drill, also known as a deep hole cutting insert drill, represents an advanced and efficient solution for deep hole machining. It integrates drilling, boring and reaming into a single operation, enabling high – precision hole processing in one pass. Crafted from premium carbide materials with specialized coating and structural design, it excels in handling harsh machining conditions while maintaining excellent stability and long service life, making it a core tool for precision manufacturing across multiple industries.

| Parameter Category | Specific Details |

| Basic Dimensions | Drilling Diameter: 8 - 60mmOverall Length (OAL): 10 - 4000mm (customizable)Length - to - Diameter Ratio (L/D): 8 - 45, capable of processing deep holes with a ratio up to 1:250Shank Diameter: 25mm (standard), customizable for different machine interfacesShank Length: 570mm (standard), available in polished straight shank and other types |

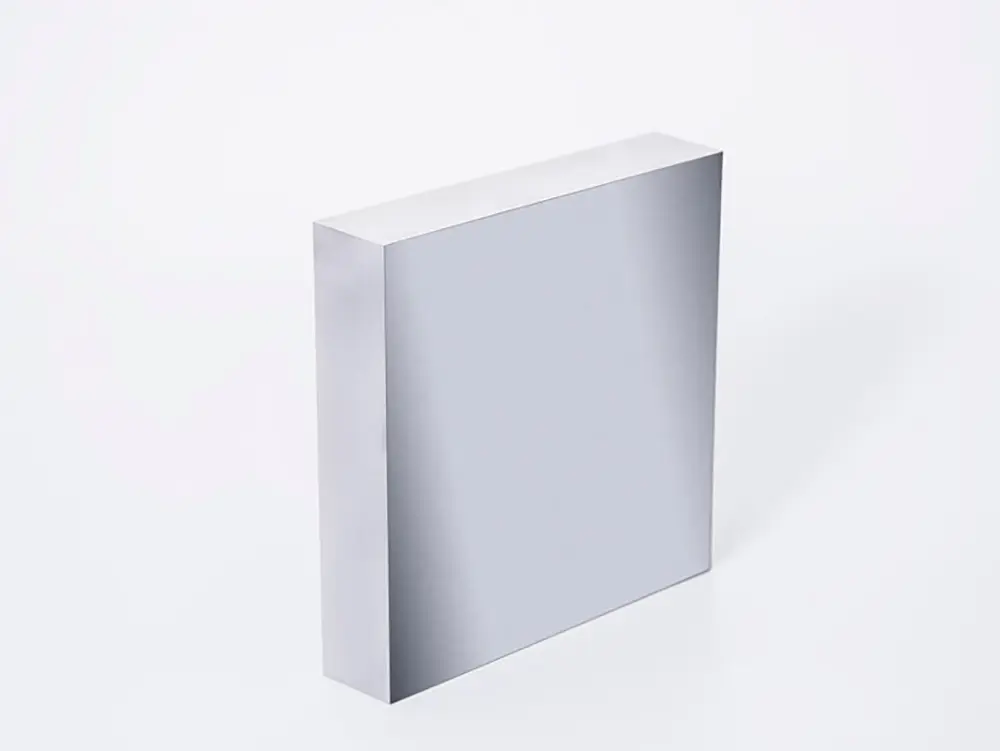

| Material & Hardness | Insert Material: WC + Co + 65# SteelGrain Size: 0.4 - 1.2μmHardness: HRA 87.5 - 93; applicable to workpieces with hardness > 45HRCMain Insert Grades: AH9130, AH725, FH3125, FH3135- AH9130: Suitable for multi - material drilling with high wear resistance- AH725: Balances wear and chipping resistance, ideal for steel and stainless steel- FH3125: Premium grade for guide pads with long tool life via special substrate and coating- FH3135: High fracture resistance, perfect for water - soluble coolant scenarios |

| Cutting Performance | Cutting Speed: 30 - 150m/min (varies by workpiece material)Feed Rate: 0.015 - 0.13mm/revTensile Strength (T.R.S): 2500 - 4500N/mm²Processing Precision: Hole accuracy up to IT6 - 8 grade; straightness: 0.16 - 0.33mm/1000mm; surface roughness: Ra 0.1 - 3.2μm |

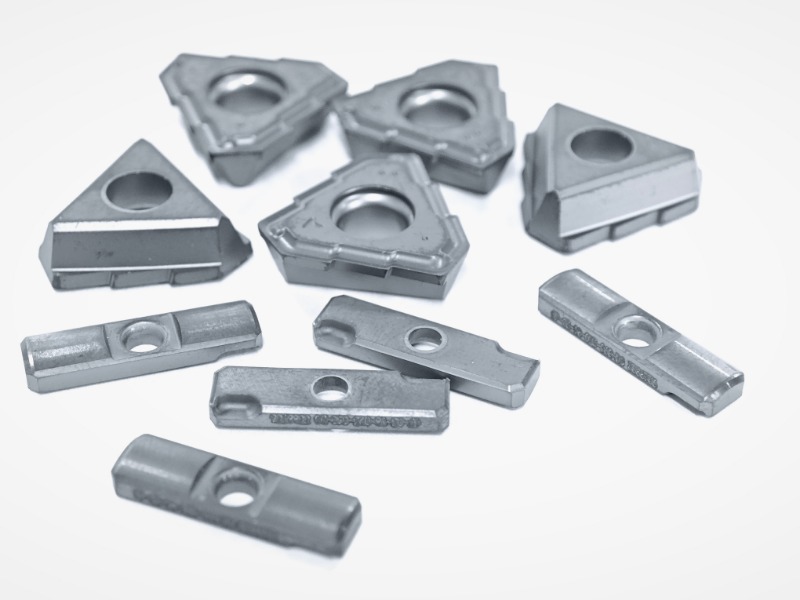

| Insert & Structural Design | Insert Types: 1 - edge single - sided insert, 2 - edge insert, 3 - edge insert (with chip splitter)Coating Options: TiAlN, AlCrN, DLC (for difficult - to - machine alloys like Inconel) and uncoated versionsCoolant System: Built - in through - hole for coolant circulation; recommended coolant pressure: 2.5 - 6.0Mpa; flow rate: 0.2 - 0.65L/s |

| Customization & Others | Minimum Order Quantity: 1 PCWarranty Period: 3 yearsCustomization Support: OEM, ODM, OBM; logo and dimension customization available |

This carbide gun drill is widely applied in industries requiring high - precision deep hole machining, with typical application scenarios as follows:

1.Automotive & Engine IndustryIt is used for machining key components such as engine shafts, cylinder blocks, and fuel injection pump bodies. For example, drilling deep holes in SCM420H shafts and hydraulic system parts. It ensures the tight tolerance requirements of automotive parts, which is crucial for the stable operation of the engine and transmission system.

2.Aerospace IndustryIt processes titanium alloys, nickel - chromium alloys and other high - strength materials for aircraft engine casings, landing gear components and aerospace structural parts. Its excellent wear resistance and heat resistance can cope with the difficult - to - machine characteristics of aerospace materials.

3.Die & Mold IndustryIt is suitable for drilling cooling holes and through - holes in plastic molds (e.g., SKD61 material with 45HRC hardness) and stamping dies. The high hole surface finish it provides avoids secondary polishing and improves mold production efficiency and product quality.

4.Heat Exchanger & Pipe IndustryIt drills tube sheets made of SUS304 and X5CrNi18 - 9 stainless steel. The efficient chip evacuation design ensures smooth drilling even in large - area tube sheet machining, and the high roundness of the holes guarantees the sealing performance of heat exchanger tubes.

5.General Machinery & HardwareIt is used in the production of hydraulic cylinders, gearboxes, and mining machinery parts. It can process various materials including carbon steel, cast iron, copper and aluminum alloys, meeting the diverse drilling needs of general machinery manufacturing.

1.Superior Durability & Wear ResistanceThe insert is made of fine - grain carbide (WC + Co) with a hardness of HRA 87.5 - 93, which can resist severe wear during high - speed cutting. The optional advanced coatings (TiAlN, AlCrN, etc.) further enhance oxidation resistance and reduce friction between the tool and the workpiece, extending the tool life by 3 - 5 times compared with ordinary drills.

2.High - Precision Machining CapabilityThe special cutting edge geometry and optimized guide pads ensure exceptional hole quality. It achieves IT6 - 8 grade hole accuracy, excellent straightness and roundness, and a smooth surface with Ra 0.1 - 3.2μm. This eliminates the need for subsequent finishing processes, saving production time and costs.

3.Efficient Chip EvacuationAll inserts are equipped with integrated chip splitters and optimized chip breaker designs. Regardless of the feed rate, they can split chips into narrow and easy - to - remove fragments. Matched with the built - in high - pressure coolant channel, chips are quickly discharged from the deep hole, avoiding chip jamming that may damage the tool or workpiece. It can work normally even under the standard coolant pressure of 1 - 2Mpa.

4.Strong Versatility & CustomizationIt covers a wide range of insert grades and sizes, suitable for machining diverse materials such as carbon steel, stainless steel, titanium alloy, cast iron, aluminum alloy and nickel - chromium alloy. We provide OEM, ODM and OBM services, supporting customization of dimensions, coatings and shank types to match different machine tools and special machining needs.

6.Stable & Reliable OperationThe insert adopts a direct mount design, requiring no adjustment for accurate hole diameter, which reduces operation errors. The high tensile strength (2500 - 4500N/mm²) ensures the tool does not deform or break during high - speed rotation. It is compatible with both horizontal and vertical machining centers, lathes and specialized gun drill machines, adapting to various production line configurations.