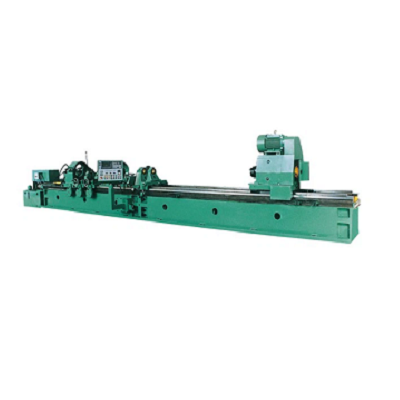

Technical Parameters Item Specification Range Honing Diameter Range Φ25mm – Φ1000mm Max Honing Depth 1m – 20m Hole Accuracy Grade IT7 – IT9 Surface Roughness Ra 0.2μm – 0.4μm Spindle Speed 25r/min – 250r/min (Stepless) Reciprocating Speed 3m/min...

| Item | Specification Range |

| Honing Diameter Range | Φ25mm - Φ1000mm |

| Max Honing Depth | 1m - 20m |

| Hole Accuracy Grade | IT7 - IT9 |

| Surface Roughness | Ra 0.2μm - 0.4μm |

| Spindle Speed | 25r/min - 250r/min (Stepless) |

| Reciprocating Speed | 3m/min - 20m/min |

| Cooling System Flow | 100L/min - 200L/min |

| Machine Weight | 2200kg - 5800kg |

• Hydraulic/pneumatic industry: Hydraulic cylinders, pneumatic cylinders, precision pipes.

• Automotive manufacturing: Engine blocks, crankcase oil channels/cooling holes.

• Aerospace: Aircraft engine blade cooling holes, turbine disk oil passages.

• Construction machinery: Coal mining equipment, large hydraulic components.

• Mold/energy industry: Precision mold cavities, oil/gas equipment pipes.

1、High Precision: Corrects taper/ovality to ensure hole roundness/cylindricity.

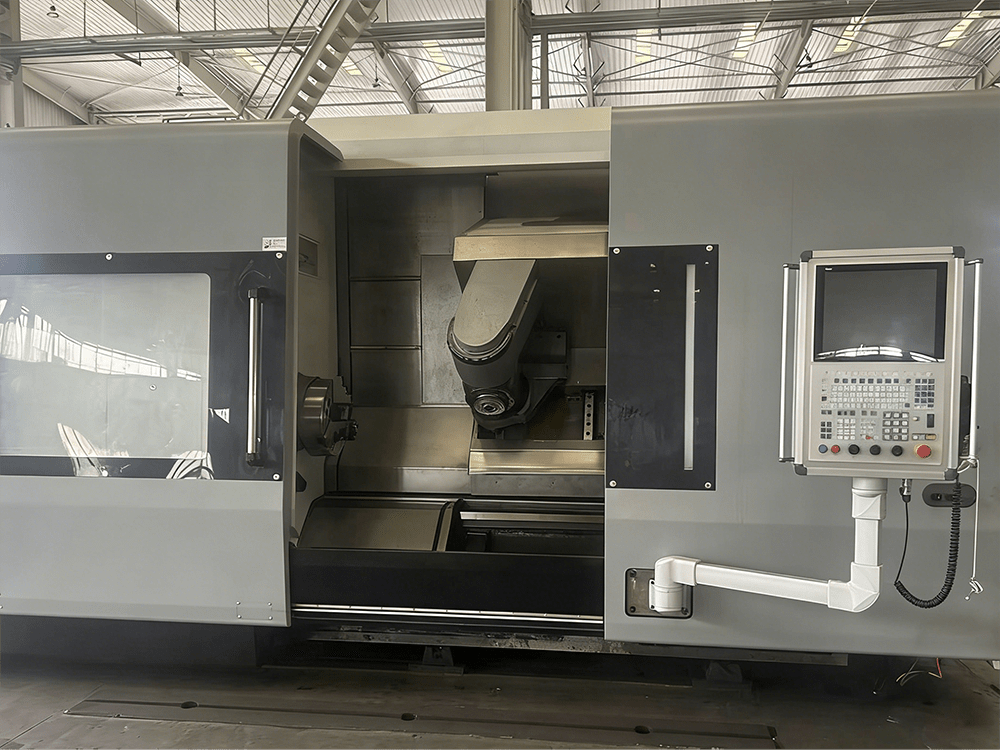

2、Efficient & Intelligent: Equipped with CNC system (Siemens/FANUC) + servo motor, supporting automatic rough/fine honing switch.

3、Strong Adaptability: Directly hones cold-drawn steel tubes; compatible with cast iron, hardened steel, etc.

4、Stable & Durable: Hydraulic constant-pressure honing head (stable abrasive force); double linear guides for long service life.

5、Customizable: Optional CNC system, guides, hydraulic valves, etc., based on requirements.

| Category | Item | Specification Range |

| Basic Processing Capacity | Max Honing Diameter | Φ25mm - Φ1000mm (Customizable to Φ1200mm) |

| Min Honing Diameter | Φ25mm (Mini model supports Φ15mm) | |

| Max Honing Depth | 1m - 20m (Ultra-long stroke model supports 30m) | |

| Hole Length-Diameter Ratio | 1:5 - 1:200 | |

| Accuracy Index | Hole Size Accuracy | IT7 - IT9 (Precision model up to IT6) |

| Hole Roundness | ≤0.003mm | |

| Hole Cylindricity | ≤0.005mm/1000mm | |

| Surface Roughness | Ra 0.2μm - 0.4μm (Ultra-precision model up to Ra 0.05μm) | |

| Hole Straightness | ≤0.01mm/1000mm | |

| Spindle System | Spindle Speed | 25r/min - 250r/min (Stepless frequency conversion) |

| Spindle Drive Mode | Servo motor (Power: 5.5kW - 37kW) | |

| Spindle Runout Accuracy | ≤0.002mm | |

| Reciprocating System | Reciprocating Speed | 3m/min - 20m/min (Servo-controlled, accuracy ±0.1mm) |

| Reciprocating Stroke Range | 50mm - 2000mm (Customizable for longer strokes) | |

| Reciprocating Drive Mode | Servo motor + ball screw/gear rack | |

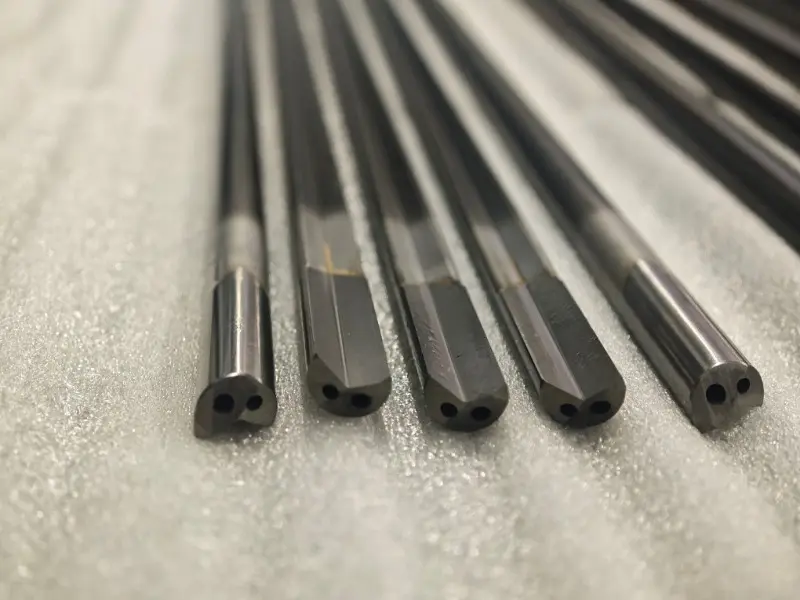

| Honing Head System | Honing Head Type | Hydraulic constant-pressure / Mechanical expansion / Pneumatic servo (Optional) |

| Abrasive Strip Quantity | 4/6/8 strips (Matched with hole diameter) | |

| Abrasive Strip Specification | Width 15mm - 50mm, Length 50mm - 300mm | |

| Abrasive Strip Pressure Range | 0.5MPa - 5MPa (Stepless adjustment) | |

| Cooling & Filtration System | Cooling Pump Flow | 100L/min - 200L/min |

| Filtration Precision | 10μm - 20μm (Multi-stage filtration) | |

| Cooling Medium | Emulsion / Honing oil (Compatible) | |

| CNC System | Control System Brand | Siemens 828D / Fanuc 0i-MF / Huazhong HNC-818 (Optional) |

| Function Configuration | Automatic cycle, rough/fine/superfinishing switching, parameter storage (≥100 groups), fault alarm | |

| Machine Structure | Bed Material | High-strength cast iron (Aging treatment) |

| Guide Rail Type | Heavy-duty linear guide (Accuracy grade P4) | |

| Feeding Mode | Servo motor + precision ball screw (Accuracy grade C3) | |

| Electrical Parameters | Power Supply Voltage | 380V/50Hz (Customizable to 220V/60Hz) |

| Total Power | 15kW - 55kW | |

| Overall Dimensions | Length×Width×Height | 3500mm×1800mm×2200mm - 8000mm×2500mm×3000mm (Depends on stroke) |

| Machine Weight | Total Weight | 2200kg - 5800kg (Ultra-long stroke model up to 12000kg) |