Cobalt-based superalloys are a class of high-performance metallic materials designed to maintain exceptional mechanical strength, surface stability, and corrosion resistance at extremely high temperatures, often exceeding those where nickel-based superalloys begin to weaken. They are a cornerstone material for critical components in the most demanding environments, particularly in aerospace, industrial gas turbines, and medical implants.

Their superior performance stems from a strengthened cobalt-chromium matrix and a high volume of hard, refractory carbide particles.

Exceptional High-Temperature Strength: Cobalt alloys exhibit higher melting points and better hot hardness and creep resistance than nickel alloys at temperatures above 1000°C (1832°F). This means they resist softening and deformation under stress at near-melting-point temperatures.

Outstanding Wear & Galling Resistance: Their inherent hardness, often enhanced by a network of hard carbides, provides excellent resistance to abrasive wear, adhesive wear (galling), and fretting. This makes them ideal for wear-facing applications.

Excellent Hot Corrosion & Oxidation Resistance: The high chromium content (often over 20%) forms a protective, adherent chromium oxide (Cr₂O₃) scale that resists degradation in oxidizing and sulfidizing atmospheres.

Superior Thermal Fatigue Resistance: They can withstand repeated cycles of heating and cooling without cracking, a critical property for components like turbine vanes.

The performance of cobalt superalloys is derived from several key mechanisms:

Solid-Solution Strengthening: Elements like tungsten (W) and molybdenum (Mo) dissolve in the cobalt matrix, impeding dislocation movement.

Carbide Precipitation: The formation of hard carbides (e.g., Cr₇C₃, Cr₂₃C₆, WC, TaC) throughout the microstructure provides immense resistance to creep and wear. The size, type, and distribution of these carbides are critical to performance.

The Cobalt Allotropy: Cobalt undergoes a phase transformation upon heating, and this characteristic is exploited to enhance properties through heat treatment and thermo-mechanical processing.

Cobalt-based superalloys are indispensable in applications where failure is not an option.

Aerospace & Power Generation Turbines: Used for stationary components like:

Turbine Vanes & Nozzle Guide Vanes: Where the highest gas temperatures are encountered and creep resistance is paramount.

Industrial Wear Components: The basis for Stellite™ alloys, used for:

Valve Seats & Trim in high-pressure, high-temperature valves.

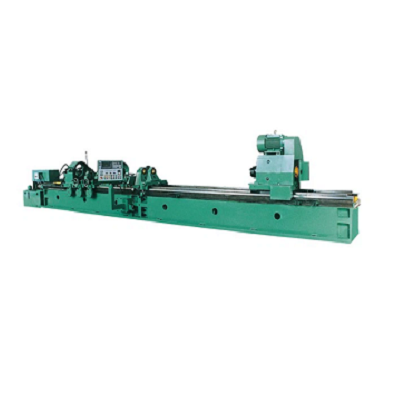

Hardfacing Wires & Rods to coat critical wear surfaces on tools and machinery.

Pump Sleeves, Shafts, and Cutting Knives.

Medical Implants: Used in orthopedic implants (especially for metal-on-metal bearing surfaces) due to their excellent biocompatibility, wear resistance, and corrosion resistance in the human body.

The following table summarizes the key features for a quick overview:

| Feature | Description | Advantage |

| Base Element | Cobalt (Co), with a high Chromium (Cr) content. | Provides the fundamental matrix for high-temperature performance and corrosion resistance. |

| Key Strengtheners | Tungsten (W), Molybdenum (Mo), and Carbon (C) for carbide formation. | Imparts high-temperature strength, creep resistance, and wear resistance. |

| Operating Temperature | Very high, excelling above 1000°C (1832°F). | Enables higher engine efficiencies and performance in extreme environments. |

| Key Properties | Hot Hardness, Creep Resistance, Wear & Corrosion Resistance. | A unique combination for the most severe service conditions. |

| Common Forms | Cast components, wrought bar/plate, powder for HIP, hardfacing alloys. | Versatile manufacturing for both complex near-net-shape parts and protective coatings. |

| Primary Industries | Aerospace, Power Generation, Medical, Chemical & Petrochemical. | The material of choice where extreme temperature and wear converge. |

In summary, Cobalt-Based Superalloys are niche but critical materials that push the boundaries of high-temperature engineering. While often more expensive and denser than nickel superalloys, their unmatched performance in specific areas—particularly very high-temperature strength, thermal fatigue, and wear resistance—secures their vital role in advanced technology.