Comma face grooving cutters (also known as comma grooving cutters or face comma cutters) are specialized tools in CNC machining for processing annular face grooves and special-shaped face grooves. They are named for their cutting edge cross-section resembling a “comma (,)” shape,...

Comma face grooving cutters (also known as comma grooving cutters or face comma cutters) are specialized tools in CNC machining for processing annular face grooves and special-shaped face grooves. They are named for their cutting edge cross-section resembling a “comma (,)” shape, and are primarily used to address working conditions that ordinary grooving cutters cannot handle, such as asymmetric face grooves and narrow-deep face grooves. Below is a detailed description from the perspectives of structure, parameters, and applications:

Cutting edge morphology: The cutting edge consists of a straight segment (main cutting edge) and an arc segment (transitional cutting edge), forming an overall comma profile — the straight segment is responsible for groove bottom/groove wall cutting, while the arc segment adapts to groove mouth transitions or special-shaped groove profiles. The cutting edge is sharp with no corner blind spots, capable of machining narrow grooves with a minimum width of 0.5mm.

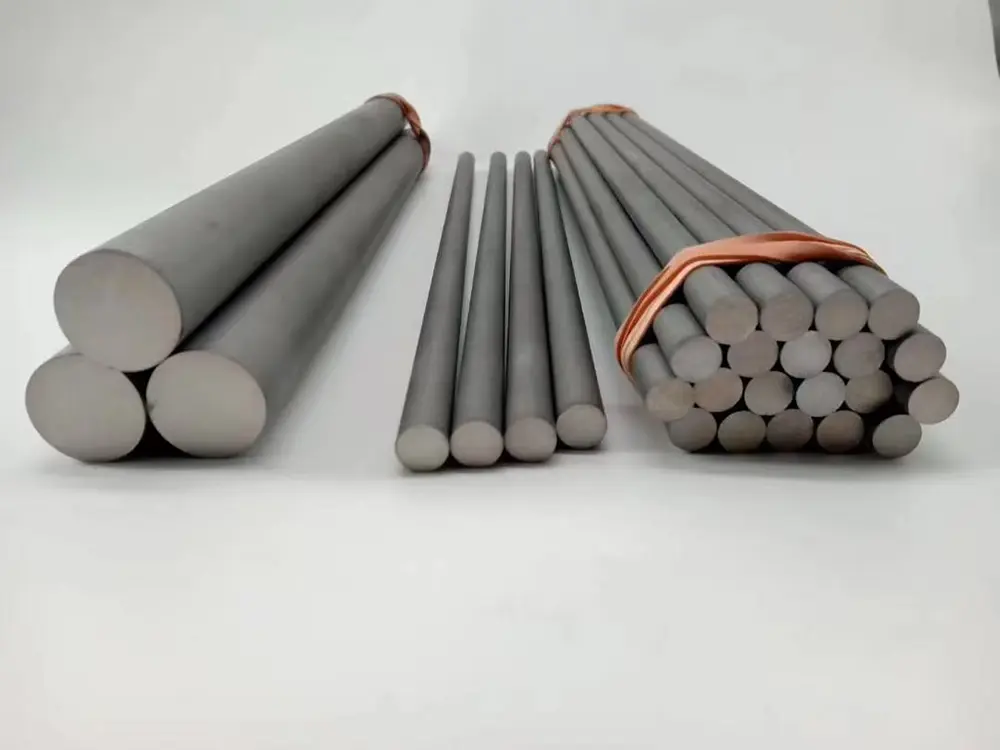

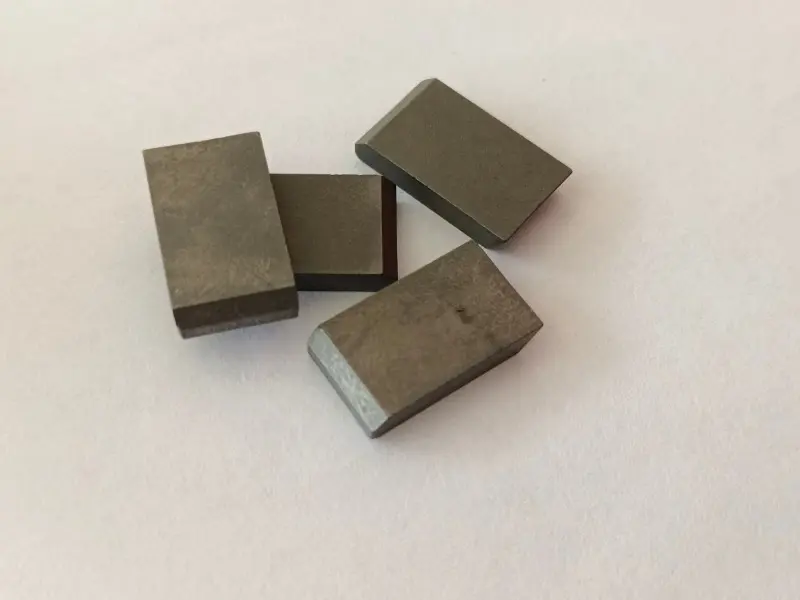

Cutter body structure: Adopts an integral cemented carbide (WC-Co) or brazed insert structure (the insert material is cemented carbide/PCD, and the cutter bar is alloy steel). The cutter bar is designed as a straight bar or a 90° bent bar to meet the clearance requirements during face machining. Some models are equipped with internal cooling holes (chip removal via high-pressure coolant).

Positioning accuracy: The insert and cutter bar use a high-precision positioning groove (positioning accuracy ±0.005mm), with radial runout ≤0.01mm after clamping, ensuring dimensional consistency of face grooves.

Typical Machining Objects:Annular grooves and seal grooves on the end face of hydraulic valve blocks;Positioning grooves and special-shaped mounting grooves on the end face of motor end covers;Oil grooves and labyrinth grooves on the end face of bearing blocks;Narrow-deep special-shaped grooves on the end face of aerospace components (e.g., end face grooves of engine casings).

Process Advantages:Solves the problem of “end face machining interference” with ordinary grooving cutters (the bent design allows close proximity to the workpiece end face);Asymmetric groove profiles are formed in one pass (no multiple passes required), increasing machining efficiency by over 30% compared to ordinary grooving cutters;No risk of cutting edge chipping, and the machined surface roughness can reach Ra0.4μm, meeting the precision requirements of precision end face grooves.