Large aperture deep hole drill i a deep hole machining machine that integrates BTA drill cutter drill,and gun dril,with a driling diameter of up to φ120mm.

High efficient,high-precision,and high smoothness machining of large holes,with a smoothness of Ra0.4~0.8.

Horizontal layout; simultaneously supports both gun drilling (external chip removal) and BTA (internal chip removal) machining modes. These two modes cannot be used concurrently; for example, BTA cannot be used while gun drilling is in operation. The workpiece is fixed to a dedicated fixture, and the tool rotates and feeds.

BTA can only machine coaxial holes, while gun drilling can machine both coaxial and eccentric holes.

Employs a dual-spindle structure; the gun drill rod box and the BTA drill rod box are mounted on a single support plate, sharing a common feed system.

CNC System: KND system

Servo Axis: Z-axis, controls tool feed

Machining Diameter Range:

Gun Drill: Φ5mm~Φ30mm

BTA: Φ25mm~Φ80mm

Maximum Machining Depth: 1000mm

Drilling Deviation: 1mm/1000mm

Roughness: Ra0.8~Ra6.3um

Dimensional Accuracy: IT8~IT11

Workpiece clamping during BTA machining: The workpiece is clamped and positioned using chamfered ends, a tapered disc, a guide sleeve, and a hydraulic system. The workpiece is first placed on an auxiliary support, and the hydraulic system controls the tapered disc to press against the chamfered ends of the workpiece, achieving workpiece clamping and positioning.

Workpiece clamping during gun drilling: The workpiece is placed on a V-block and manually clamped. The gun drilling fixture can move laterally, suitable for eccentric hole machining, with a travel stroke of 150mm. Replace the pads on the V-block when the workpiece diameter is different.

(1) Simultaneously supports both gun drilling (external chip removal) and BTA (internal chip removal) machining methods.

(2) The bed, housing, worktable, and other basic components are made of high-quality cast iron.

(3) A suspended CNC system operating table facilitates machine tool operation. (4) Equipped with a dedicated cooling system: consisting of an automatic chip conveyor, oil cooler, filtration system, and high-pressure pump unit.

(5) Employs the KND system.

(6) The Z-axis feed guide is a double rectangular sliding guide, providing high rigidity.

(7) Tool rotation is driven by the spindle motor, and tool feed is achieved through a servo motor driving a ball screw. Both tool rotation and feed are infinitely variable.

(8) The main unit uses a flow-type protective cover.

(9) Electrical system: Employs the KND CNC system, which can be programmed to complete automatic machining cycles, and also allows for manual, jogging, and on/off adjustments.

(10) The machine tool has functions such as pressure protection, cooling system liquid level and temperature protection, tool protection, and stroke protection.

| Technical Specifications | parameter | Remark | ||

| Scope of work | Drilling diameter range | Gun drill: Φ5~Φ35mm | ||

| BTA:Φ25~Φ80mm | ||||

| Maximum drilling depth | 1000mm | |||

| Maximum workpiece length | 1000mm | |||

| Machine tool performance | Gun drill rod box | Speed range | 600~6000rpm | Variable |

| Main motor power | 5.5KW | spindle motor | ||

| BTA Drill Pipe Box | Speed range | 200~2000rpm | Variable | |

| Main motor power | 30KW | spindle motor | ||

| Z-axis | Feed rate range | 5~500mm/min | Variable | |

| Fast movement speed | 2000mm/min | |||

| Motor torque | 20Nm | |||

| other | Drill length-to-diameter ratio | ≤100 | ||

| Total power of the machine tool (approximately) | 85kW | |||

| Machine tool floor space (approximately) | 7m (length) × 3m (width) | |||

| Machine tool weight (approx.) | 12 tons | |||

| CNC system | FANUC 0i Mate TD system | |||

| Cooling system | Cooling system pressure range | 1~10MPa | Adjustable | |

| Cooling system flow range | 100、200、300L/min | Adjustable | ||

| Filtration accuracy | 40μm | |||

1. Machine Bed

Made of high-quality cast iron with a closed casting structure, providing the machine tool with sufficient rigidity and strength. Double rectangular sliding guideways are machined onto the bed, and these guideways undergo medium-frequency quenching.

2. Drill Rod Box

Main components: Drill rod box for gun drills, drill rod box for BTA (Boiler Actuation), and feed slide.

Two drill rod boxes are mounted on the slide.

Drill rod box for gun drills: Drives the tool rotation and supplies oil to the tool.

Drill rod box for BTA: Drives the tool rotation and provides a chip removal channel for drilling.

Common features of both drill rod boxes: Spindle motor drives spindle rotation with stepless speed regulation; rear-mounted main motor prevents cutting oil from entering the motor and facilitates tool changing; high-precision angular contact ball bearings with automatic lubrication.

3. Feed System

Uses an AC servo system for drive, with stepless speed regulation, ranging from 5 to 500 mm/min. Utilizes a ball screw drive. The feed guide is a double rectangular sliding guide, which is hardened by medium frequency and precision ground, thus possessing advantages such as high precision, long service life, high rigidity, and good accuracy retention.

4. Cooling System

Equipped with a dedicated cooling system, providing high-pressure, high-flow-rate, and high-cleanliness cutting fluid for deep hole drilling.

Automatic chip conveyor: Automatically removes chips, achieving initial oil-chip separation.

Oil cooler: Controls cutting fluid temperature and prevents cutting fluid deterioration.

Filtration system: Paper tape, mesh, and magnetic rod filters improve cutting fluid cleanliness.

High-pressure pump set: Generates cutting oil with adjustable flow and pressure to supply oil to the cutting tools.

5. Centralized Lubrication System

The front and rear bearings of the drill rod box spindle, the slide guide surfaces, etc., are all automatically lubricated with timed and metered lubrication. The oil tank has an automatic low oil level alarm function.

6. Electrical System

Employs a KND system, which can be programmed to complete automatic machining cycles, and can also be manually operated, jogged, and adjusted for start/stop. The CNC system control panel is suspended.

It features ladder diagram display, is programmable, and supports Chinese display.

It has reliable interlocking, safety protection, over-torque protection, or other fault diagnosis, alarm, and protection functions, emitting audible and visual signals (red, yellow, and green column lights).

7. Guide Frame and Oil Feeder

The guide frame and oil feeder are mounted on the slide. The slide is axially moved by the guide sleeve controlled by the hydraulic system to tighten or loosen the workpiece.

Guide Frame: Used for gun drilling; Functions: drill bit guidance, oil sealing, chip removal, and tool holder support.

Oil Feeder: Used for BTA (Boiler Actuation) machining; Functions: drill bit guidance, oil sealing, tool oil supply, and tool holder support.

8. Drill Rod Support

Two sets, providing drill rod support and vibration damping.

9. Hydraulic System

Controls the guide frame and oil feeder to tighten or loosen the workpiece, and provides a seal during drilling to prevent cutting fluid splashing.

10. Fixtures

BTA: Utilizing chamfered ends, a tapered disc, guide sleeves, and a hydraulic system, the workpiece is clamped and positioned. The workpiece is first placed on an auxiliary support, and the hydraulic system controls the tapered disc to press against the chamfered ends of the workpiece, achieving clamping and positioning.

Gun Drill: The workpiece is placed on a V-block, and a hydraulic rotary cylinder automatically clamps the workpiece. The gun drill fixture can move laterally, suitable for machining eccentric holes, with a travel stroke of 100mm. When the workpiece diameter is different, the pads on the V-block can be replaced.

11. Sliding Semi-Protective System

The machine bed is equipped with oil baffles and a sliding door, fully considering the convenience of loading and unloading workpieces and tools.

Accessories: Special order, cost borne by the user.

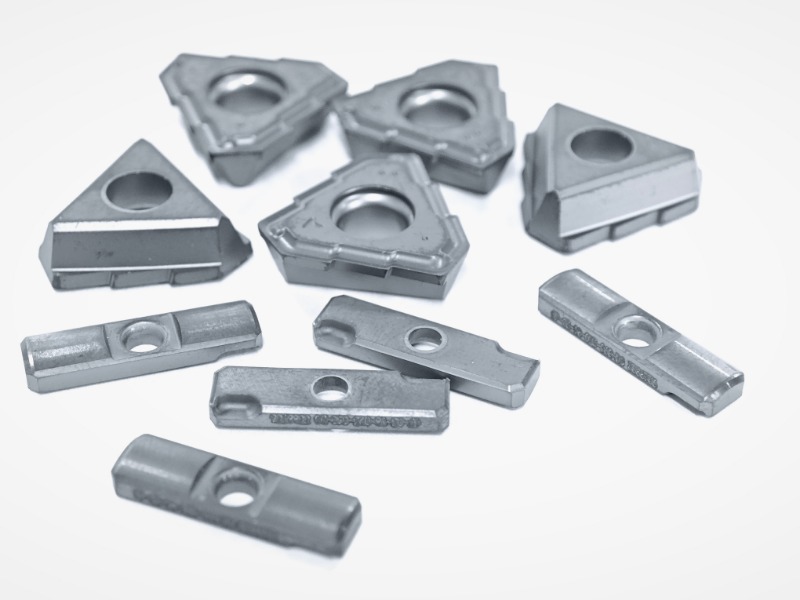

Cutting Tools: Provided by the user or procured by us, used for pre-acceptance and final acceptance of the machine tool, cost borne by the user.

Cutting Oil: Provided by the user for final acceptance.

One copy of the machine tool instruction manual, one copy of the certificate of conformity, and one copy of the packing list. One copy of the CNC system operation and maintenance manual.

1. Pre-acceptance by the user at the machine tool manufacturer's factory. Machining one workpiece; test piece and cutting tools provided by the user; acceptance according to item 2.

2. Final acceptance at the user's factory. Machining two workpieces; test piece and cutting tools provided by the user; acceptance according to item 2. Upon successful completion, both parties sign the final acceptance minutes, which become effective upon signature.

1. Installation and Commissioning

After the machine tool arrives at the user's factory, the machine tool manufacturer will send personnel to guide the equipment installation and be responsible for commissioning.

2. Training: The machine tool manufacturer will provide three working days of training for the user's programming, operation, and maintenance personnel. During the training, the manufacturer will guide the user's technical and operational personnel to conduct trial production on typical parts.

3. The machine tool manufacturer strictly adheres to the after-sales service commitments of Dezhou Delong (Group) Machine Tool Co., Ltd.

4. The equipment is covered by a one-year warranty.