Service Areas Screw Motors, Rotary Steerable Systems, Downhole Drilling Tools, etc. PDC Composite Selection Selecting composite materials with high impact resistance and high wear resistance. PDC Composite Technical Specifications 1. Wear Resistance: Average volume wear ratio g...

Screw Motors, Rotary Steerable Systems, Downhole Drilling Tools, etc.

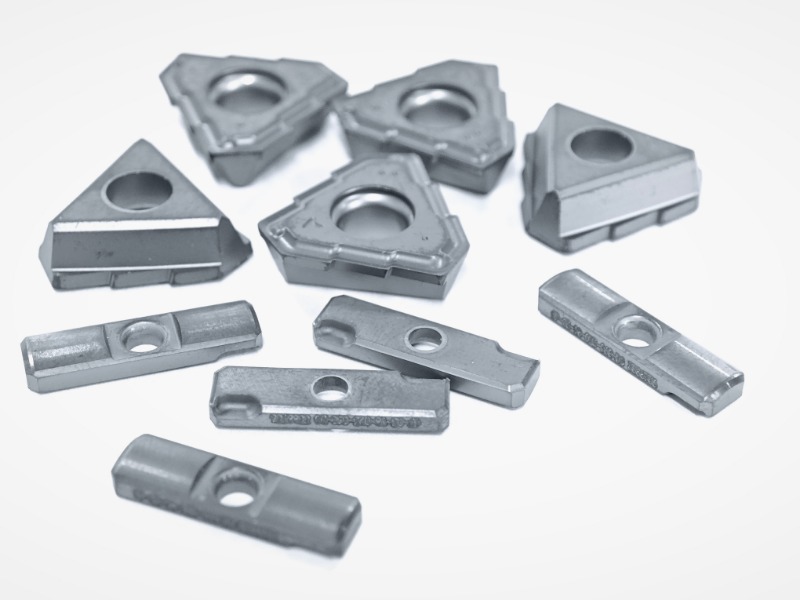

Selecting composite materials with high impact resistance and high wear resistance.

1. Wear Resistance: Average volume wear ratio greater than 400 x 10,000;

2. Heat Resistance: Heat resistance temperature not less than 700℃;

3. Impact Resistance: Cumulative impact energy ≥ 40J;

4. Diamond Layer: Under a microscope (20x magnification), no visible cracks, no obvious unevenness, no defects with a diameter > 0.15mm and a depth > 0.15mm are allowed, and the maximum edge chipping size is < 0.15mm.

| size | |||||

| Integrated impact-resistant PDC composite insert | |||||

| 1308 | 1313 | 1608 | 1613 | ||

| diameter(D)mm | 13.44±0.025 | 13.44±0.025 | 15.875±0.025 | 15.875±0.025 | |

| height(h)mm | 8.00±0.05 | 13.2±0.05 | 8±0.05 | 13.2±0.05 | |

| thickness(t)mm | 2.2±0.15 | 2.2±0.15 | 2.2±0.15 | 2.2±0.15 | |

| DiamondChamfer | |||||

| high c1 | 0.3/0.4mm | ||||

| angle a1 | 45° | ||||

| Hard alloy chamfering | |||||

| high c2 | 0.40/0.76mm | ||||

| angle a2 | 45° | ||||