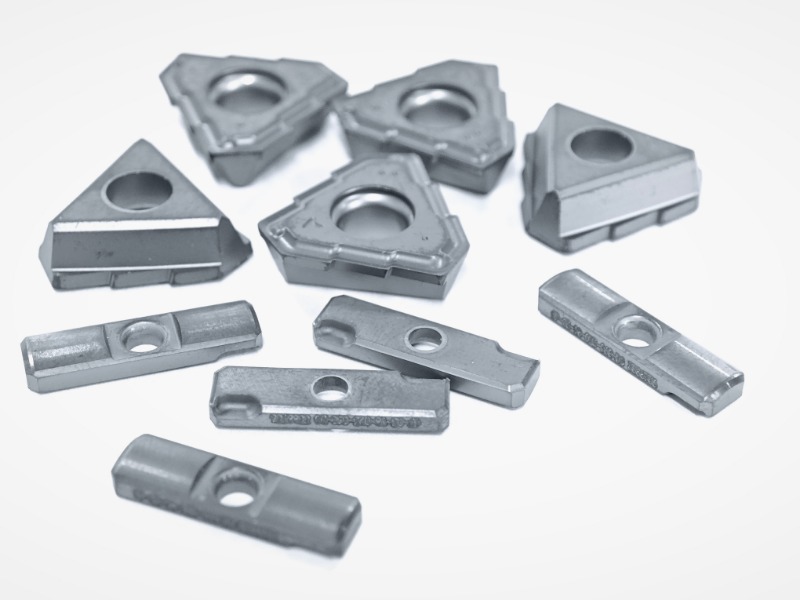

Square CNC turning inserts are one of the commonly used cutting tools in CNC turning processes.

Shape Characteristics:

Square CNC turning inserts have a tool nose angle of 90°, four cutting edges, and a total of eight usable tool noses on both sides. They feature a large insert base, which provides excellent stability during cutting and makes them suitable for heavy cutting operations.

Model Specifications:

The model of a square CNC turning insert typically includes information such as insert side length, thickness, and tool nose radius. For example, SNGN090304: “SNGN” indicates a square insert shape; “09” means the insert side length is approximately 9mm; “03” denotes an insert thickness of 3.18mm; and “04” represents a tool nose radius of 0.4mm.

Material Types:

Common materials include cemented carbide and cubic boron nitride (CBN). Cemented carbide inserts offer good wear resistance and toughness, suitable for machining various materials such as steel, stainless steel, and cast iron. CBN inserts have higher hardness and heat resistance, primarily used for machining high-hardness materials like hardened steel.

Coating Treatment:

To enhance insert performance, coating treatment is usually applied. For instance, TiAlN-coated inserts have excellent wear resistance and oxidation resistance, ideal for machining stainless steel and other materials. Ti(C,N)+Al₂O₃-coated inserts feature high cutting edge toughness and wear resistance, performing outstandingly in steel turning.

Application Scope:

Square CNC turning inserts are compatible with various external turning tools, face turning tools, and boring bars with a tool cutting edge angle of 45°, 60°, or 75°. They can be used for multiple machining operations including external turning, facing, chamfering, and internal boring, offering good versatility.