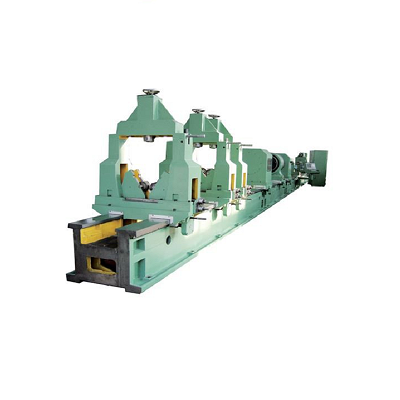

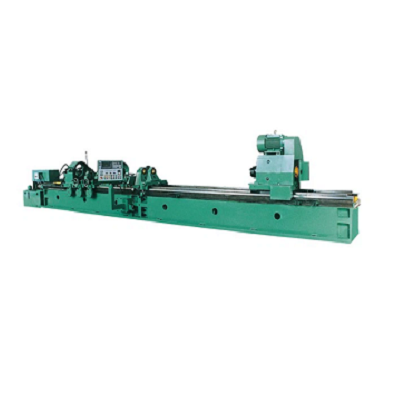

This machine tool is a special-purpose machine tool for machining cylindrical deep-hole parts. It is suitable for drilling and boring cylindrical deep-hole workpieces. During boring, an oil feeder is used to supply oil, and the chips are discharged to the chip hopper at the head of the machine through the cutting zone. During drilling, an internal chip removal method (BTA) is used, that is, an oil feeder supplies oil, and the chips are discharged from the inside of the drill rod to the chip hopper at the rear of the machine through the cutting zone.

Machine tool application: This machine tool is a special-purpose machine tool for machining cylindrical deep-hole parts. It is suitable for drilling and boring cylindrical deep-hole workpieces. During boring, an oil feeder is used to supply oil, and the chips are discharged to the chip hopper at the headstock through the cutting zone. During drilling, an internal chip removal method (BTA) is used, that is, an oil feeder supplies oil, and the chips are discharged from the inside of the drill rod to the chip hopper at the rear of the machine through the cutting zone.

The machine tool is PLC controlled, and the clamping of the oil feeder and the reciprocating motion of the feed slide are both controlled by servo motors. The transmission adopts a rack and pinion drive located in the middle of the two guide rails, ensuring the accuracy and rigidity requirements of the feed transmission during ultra-long movements. Protective devices are installed on both sides of the machine bed, and a ground-mounted oil tank structure is adopted to improve the machine tool environment. The machine tool can be equipped with manually operated high-efficiency expanding and contracting tools, which greatly improves the machining efficiency.

This machine tool is a deep hole drilling and boring machine that is easy to operate and control, efficient, and environmentally friendly.

| Project Name | T2110G

T2110G/1 |

| Drilling diameter range

(mm) |

20~60 |

| Boring hole diameter range

(mm) |

40~100 |

| Central High

(mm) |

400 |

| Maximum boring depth range

(mm) |

1000~5000 |

| Chuck diameter

(mm) |

325 |

| Center frame clamping diameter range

(mm) |

20-180 (Standard configuration) 50-400 (Special order) |

| Spindle speed range, number of stages | 70~1200r/min

Three levels, 12 stages |

| Main motor | N=15kW |

| Feed rate range

(mm/min) |

5~2000

Variable |

| feed motor | N=4.5kW

Servo motor |

| Oil feeder motor | N=4.5kW

Servo motor |

| Cooling pump motor | N=5.5kW

N=1440r/min Two groups |

| Cooling system rated pressure

(MPa) |

2.5、6.5 |

| Cooling system flow

(L/min) |

80 180

280 |

| If equipped with a variable frequency motor | Spindle rotation range (r/min)

series |

Main motor |

| 60~1200

Three-speed continuously variable transmission |

N=22Kw

Variable frequency motor |

|

| 60~1200

Three-speed continuously variable transmission |

N=37Kw

Variable frequency motor |

|

| T2110G/1 with

15Kw 60-800 r/min drill pipe box |

T2120G/1 with

15Kw 40-500 r/min drill pipe box |

|

| The main motor can be changed to 30KW.

Drilling diameter can reach 80mm |

The added small hole drilling function can process holes with a diameter of 20-40mm. | |