V-CUT knives (also known as V-shaped cutting knives or V-groove knives) are specialized tools for PCB (Printed Circuit Board) processing, metal sheet grooving, and V-groove machining of materials such as acrylic and plastic. Below is a detailed description from the perspectives of core characteristics, classification, parameters, and applications:

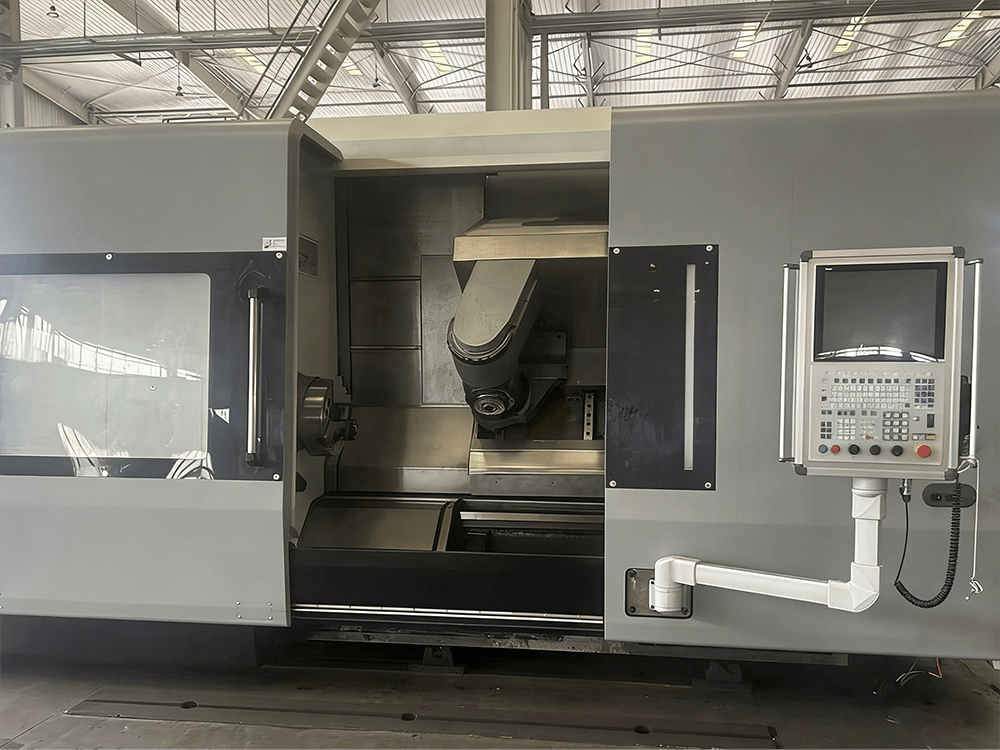

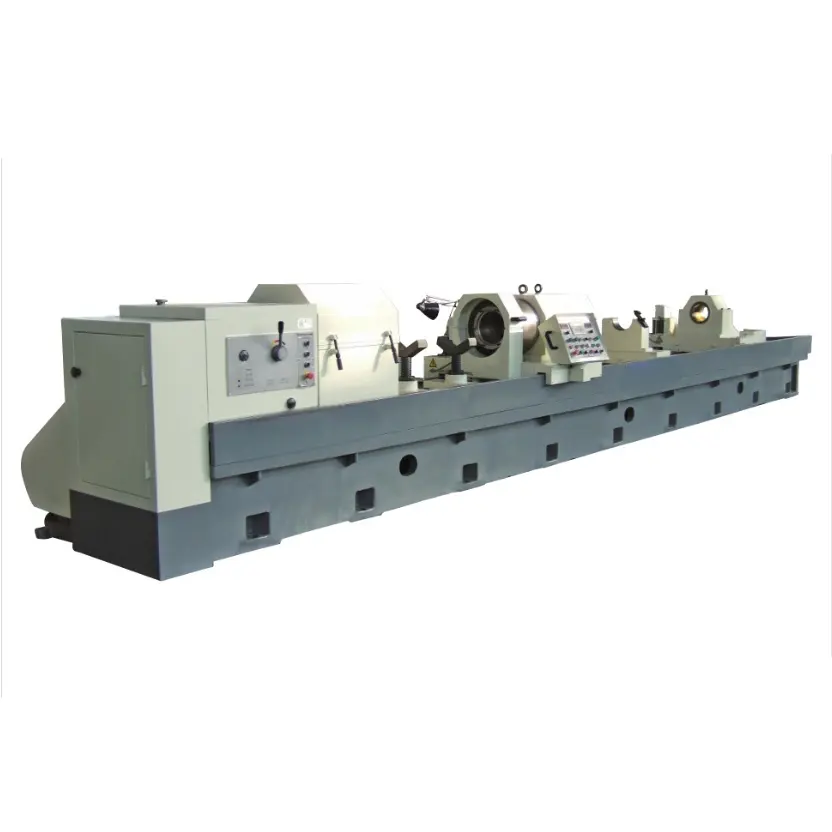

The cutting edge of a V-CUT knife features a V-shaped included angle (commonly 30°, 45°, 60°, 90°). The knife body is mostly made of a cemented carbide (tungsten steel) substrate, while some high-end models adopt PCD (Polycrystalline Diamond) or CBN coatings. The cutter head is designed with symmetric V-shaped cutting edges, paired with a central positioning hole or shank connection structure. It can be installed on V-CUT machines, engraving machines, CNC milling machines, and other equipment, achieving V-groove machining on material surfaces through rotary cutting.

V-shaped included angle: Determines the groove shape. 45°/60° are commonly used for PCB processing, 90° for metal grooving, and 30° for acrylic engraving;

Cutting edge diameter: φ3.175mm, φ6mm, φ8mm, etc. (compatible with different equipment chucks);

Cutting edge width: 0.1mm–1.0mm (corresponding to groove width; 0.1–0.3mm is selected for precision PCB processing);

Material and coating:

Cemented carbide (WC-Co): Universal type, suitable for PCBs, wood, and plastic;

PCD (Polycrystalline Diamond): High hardness, suitable for wear-resistant PCB fiberglass boards and aluminum substrates;

TiAlN coating: Enhances oxidation resistance, suitable for metal sheet grooving;

Total length / Shank diameter: Regular total length is 38mm/40mm; shank diameter is φ3.175mm (for engraving machines) or φ12mm (for V-CUT machines).